Preface: Jaw crusher, also known as tiger mouth, is a mechanical equipment that simulates the movement principle of the two jaws of animals to crush materials. It has the characteristics of simple structure, large crushing ratio, uniform product particle size, and low operating cost. It is widely used in mining, building materials, roads, railways, water conservancy and chemical industries. With its advantages of high efficiency and energy saving, jaw crusher plays an important role in these industries and has become the preferred equipment in crushing operations.

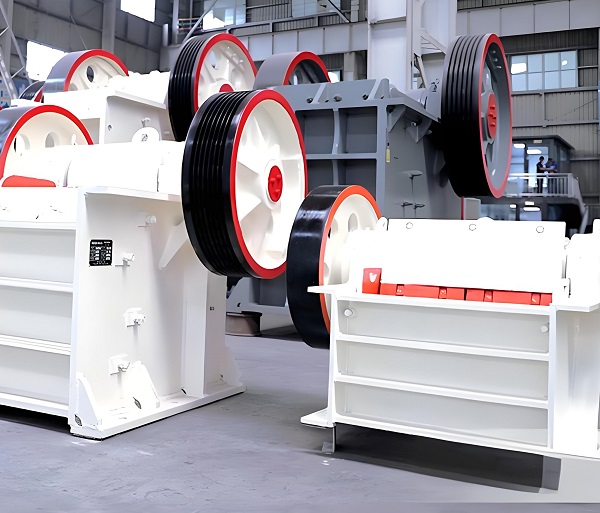

Jaw Crusher

1. Working principle of jaw crusher

As a key equipment in the field of material crushing, the jaw crusher has a sophisticated and practical structural design. Its core components include fixed jaw plate, movable jaw plate, solid frame, eccentric shaft and toggle plate. These components cooperate with each other, based on the basic principle of extrusion crushing, and efficiently complete the material crushing work.

When working, the power of the motor is transmitted to the eccentric shaft through the pulley, and the eccentric shaft rotates at high speed. The unique eccentric motion of the eccentric shaft drives the movable jaw plate to make regular reciprocating motion. When the movable jaw plate approaches the fixed jaw plate, the material between the two is subjected to the combined effect of strong extrusion force, rubbing force and bending force. As the pressure continues to increase, once it exceeds the compressive strength of the material itself, the material will be broken. When the movable jaw plate moves in the opposite direction and away from the fixed jaw plate, the material that has been crushed to a size smaller than the discharge port size is discharged smoothly from the crushing chamber under the action of gravity. Those materials that have not been completely crushed remain in the cavity, waiting for the next round of extrusion and crushing. This cycle repeats until the material is accurately crushed into a particle size that meets the requirements and is finally discharged.

Jaw Crusher

2. Uses of jaw crushers

Mining: In the mining operations of metal mines and non-metallic mines, jaw crushers have become the preferred equipment due to their powerful coarse crushing capabilities. Taking iron ore mining as an example, large pieces of raw ore mined from underground are often of large particle size and cannot be directly entered into the subsequent mineral processing process. At this time, the jaw crusher plays a key role in preliminarily crushing the raw ore to greatly reduce its particle size, meet the feeding requirements of subsequent medium and fine crushing equipment and mineral processing technology, and lay a solid foundation for the entire mining process.

Construction aggregate production: It is the core equipment in the production process of construction aggregates. In the construction field, the demand for sand and gravel aggregates is extremely large and the quality requirements are strict. Jaw crushers can accurately crush various types of rocks such as limestone and granite into gravel and stone powder according to different specifications. These aggregates are widely used in concrete mixing to provide high-strength support for buildings; they are also used for road paving to ensure the durability and flatness of roads. They are indispensable basic raw materials in the modern construction industry and are directly related to the quality and safety of construction projects.

Jaw Crusher

Metallurgical industry: In the metallurgical industry, jaw crushers undertake the important task of processing metallurgical waste slag and ore raw materials. For metallurgical waste slag, the valuable metals contained in it can be effectively recovered through crushing treatment, and efficient recycling of resources can be achieved, which not only reduces production costs, but also reduces environmental pollution. For ore raw materials, the coarse crushing effect of the jaw crusher can reduce the particle size of the ore, facilitate the subsequent smelting and purification process, and greatly improve the efficiency and quality of metallurgical production.

Industrial raw material processing: In the fields of industrial raw material processing such as chemicals and refractory materials, jaw crushers also play an irreplaceable role. In the process of chemical raw material processing, many bulk chemical raw materials need to be crushed before they can smoothly participate in the subsequent chemical reactions and ensure the quality and production efficiency of chemical products. In the production of refractory materials, precise control of the particle size of raw materials is the key to ensuring the quality and performance of refractory materials. The jaw crusher provides a strong guarantee for the production of refractory materials by crushing the raw materials to the appropriate particle size.

Jaw Crusher Technical Parameters:

| Parameter name | Parameter description | Unit | Example value |

|---|---|---|---|

| Model | Equipment model (such as PEV series, JC series, etc.) | - | PEV600×900 |

| Feed opening size | Width × length of the jaw crusher feed opening (determines the maximum feed size) | mm | 600×900 |

| Maximum feed size | Maximum material size allowed to enter the crushing chamber (usually 80%-85% of the feed opening width) | mm | ≤500 |

| Processing capacity | Material processing volume per unit time (related to material hardness, humidity, and discharge opening adjustment range) | t/h | 50-160 |

| Discharge opening adjustment range | Adjust the particle size range of the crushed material by hydraulic or mechanical means | mm | 50-150 |

| Eccentric shaft speed | The swing frequency of the movable jaw affects the crushing efficiency and output | r/min | 250-330 |

| Motor power | The power of the main motor driving the crusher (depending on the model) | kW | 75-110 |

| Equipment weight | Machine weight (without motor or with motor) | t | 15-30 |

| Overall dimensions (length × width × height) | Equipment installation space dimensions | mm | 1900×2200×1800 |

| Applicable materials | Types of materials that can be crushed (such as granite, basalt, limestone, etc.) | - | Medium hardness ore, construction waste, etc. |

| Voltage / Frequency | Motor rated voltage and frequency | V/Hz | 380V/50Hz |

| Energy saving efficiency | Energy saving ratio marked on some high-end models (compared with traditional equipment) | % | 15%-30% |

| Special functions | Optional configuration (such as hydraulic protection device, automatic lubrication system, intelligent control system, etc.) | - | Overload protection, remote monitoring |

PS: Jaw crusher plays a vital role in the field of material handling. It is mainly used to crush large pieces of material into smaller particles for subsequent processing, transportation or storage. By simulating the movement principle of the two jaws of animals, the jaw crusher can complete the crushing operation efficiently and stably. In industries such as mining, construction, and roads, jaw crushers not only improve production efficiency and reduce operating costs, but also make important contributions to the reuse of materials and resource conservation. Its powerful crushing capacity and wide range of applications make it an indispensable equipment in crushing operations.

Save Time! Get A Detailed Quotation Quickly.