1. Zhongcheng machinery can provide technological process plans and technical support and can also design non-standard supporting components according to the actual requirements of customers.

2. The whole set of equipment was purchased from our company. The equipment performed very well after the operation.

3. The total set up for limestone crushing plant is high efficienty and flexible to meet different demamds.

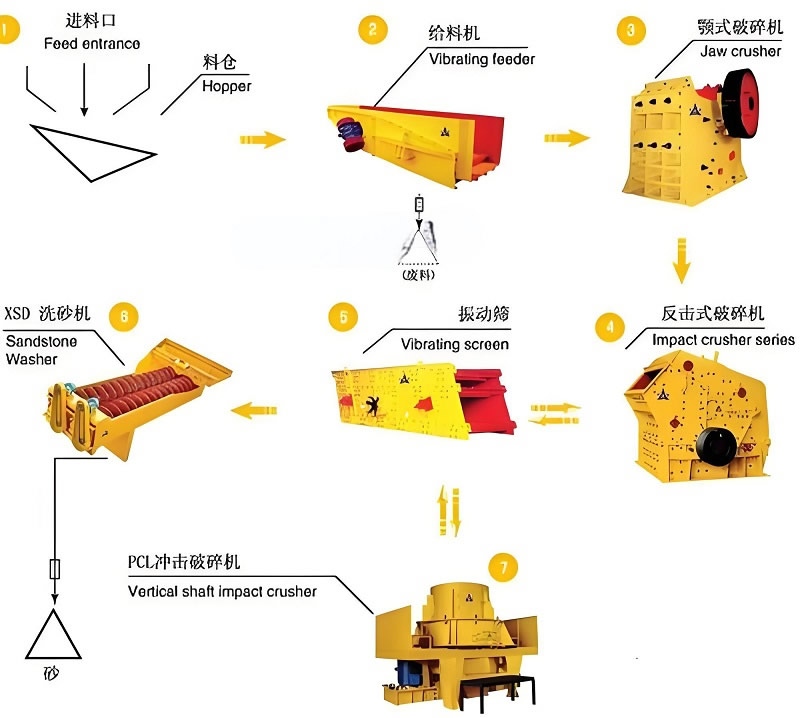

1. Feeding equipment, like vibration feeder or plate type feeder: These machines feed the jaw crusher with the rocks and stones to be crushed.

2. Crushing equipment: These are the machines where the rocks and stones are crushed. Generally jaw crushers and Gyratory crushers are used for primary crushing, while impact crusher, Symons cone crusher, sand crusher are used for secondary crushing and tertiary crushing.

3. Vibrating Screen: These machines are used to separate the different sizes of the material obtained by the crushers.

4. Belt Conveyor: They are used for transportation of the material from one machine to another during different phases of process.

5. Central electric control system: Control and monitor the operation of the entire system.

Save Time! Get A Detailed Quotation Quickly.