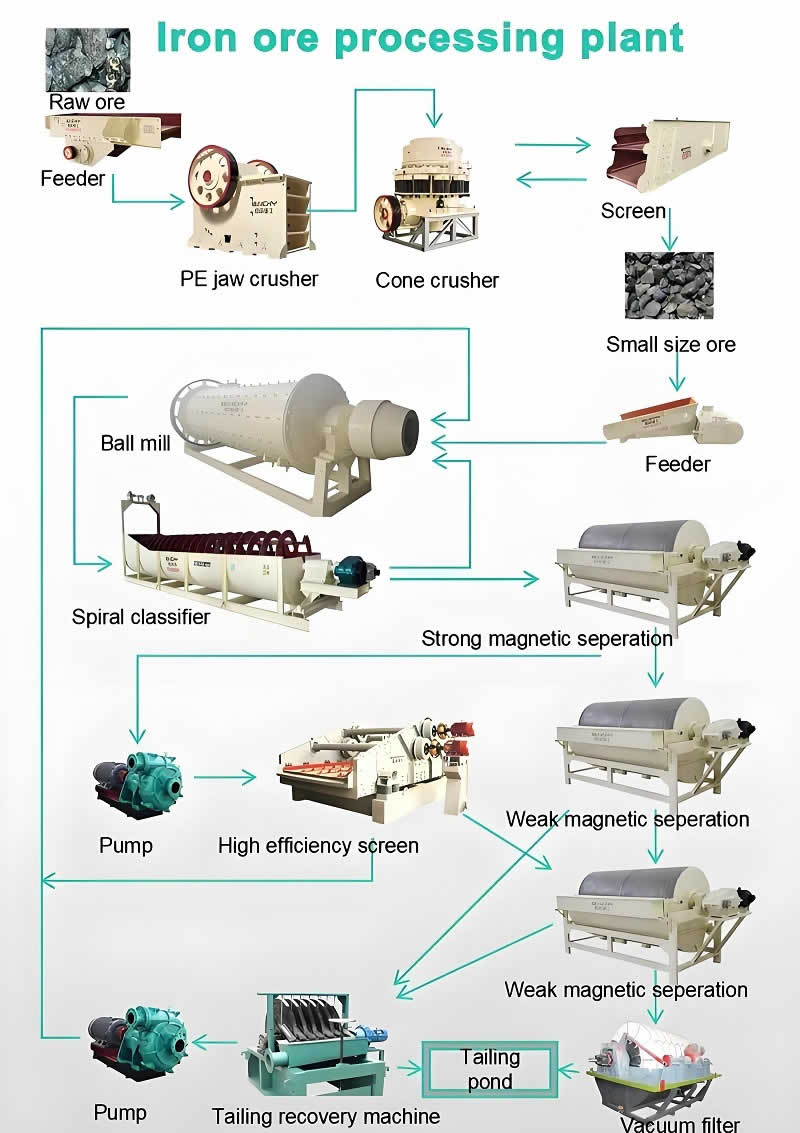

The iron ore production line system consists of a feeding system, a crushing system, and a screening and conveying system. Firstly, the material is fed through a feeder, followed by a coarse jaw crusher for preliminary crushing, followed by a fine jaw crusher for further crushing. The stones that meet the feeding particle size are sent to the sand machine for sand feeding, and finally, sand that meets the requirements is produced through the screening and washing system.

| Equipment list | Feeder,Screen,PE jaw crusher,Cone crusher,Ball mill,Feeder,Strong magnetic seperation,Pump,High efficiency screen,Weak magnetic seperation,Tailing pond,Tailing recoverymachie,vacuum filter etc. |

| Raw materials | separate copper, gold, sliver, zinc & lead, maganese ore and other non-ferrous metals and non-metallic minerals. |

| Mohz hardness | 3.0-8.5 |

| Feeding size | ≤1000mm |

| Capacity | 50-100t/h |

| Output size | 5--20mm |

| Application | Widely used in industrial sectors such as metallurgy, iron ore, gold mine, mining, etc. |

1.Crushing & screening A vibrating feeder is to evenly feed iron ore into jaw crusher and secondary cone crusher, then use vibrating screen to screened out to meet the particle size for grinding. Machine list: hopper, vibrating feeder, jaw crusher, cone crusher or hammer crusher(optional).

2.Grinding & Classifying The ore has relatively high hardness and extremely fine particle size. It adopts two-stage grinding process, which is ball mill combined with a spiral classifier to achieve the required grinding fineness. Machine list: electromagnetic vibrating feeder or similar, ball mill, sprial classifier.

3.Magnetic Separation: Separation generally adopts permanent magnet drum type magnetic separator.Most magnetite beneficiation plants often adopt coarse-grained dry magnetic separation tailings. For the ultra-lean magnetite ore with a grade below 20.00%, the ultra-fine crushing-wet magnetic separation tailing process can be used before entering the mill. That is to say, the ore is finely crushed to below 5mm-3mm, and then wet magnetic separation and tailing are carried out with a permanent magnetic field magnetic separator. Machine list: strong magnetic separator,weak magnetci separator, high efficiency screen etc.

4. Tailings treatment: After obtaining the magnetite concentrate, the tailings must be concentrated and dehydrated. After passing through the dryer, the dried mineral products can be obtained. Machine list: tailing recovery machine, vacuum filter, rotary dryer etc is optional.

Save Time! Get A Detailed Quotation Quickly.