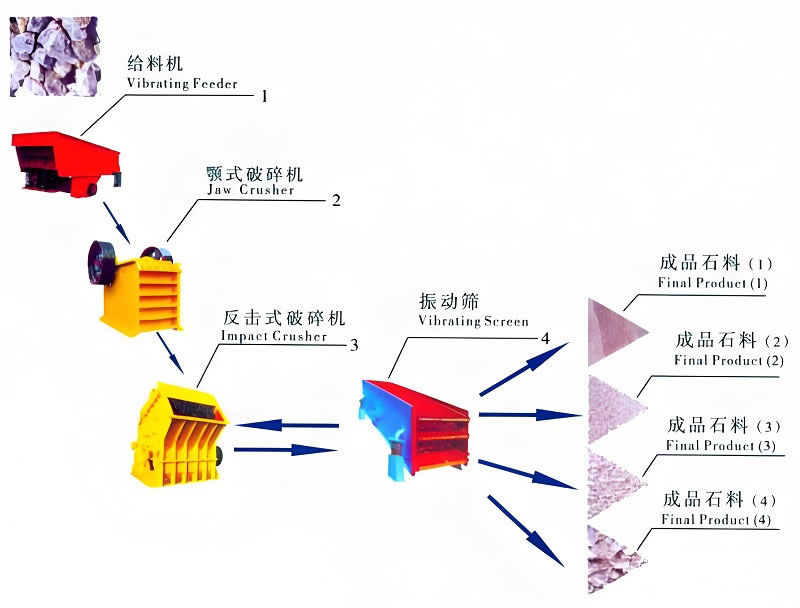

Sand making plant is a special production line for producing sand and aggregate materials for construction. In the sand making plant, natural rocks, limestone, granite, sandstones, river pebbles and other materials can be processed into artificial sand that meets the requirements of building sand. It is to replace the natural river sand for the buildings and construction industries which need high-quality aggregates. Usually the raw material is crushed by tertiary crushing process, including primary jaw crusher, secondary impact crusher or cone crusher, tertiary VSI sand crusher. To get high grade sand, sand washing machine could be added per requirement.

Equipment configuration

| Hopper, ZSW850x3000 vibrating feeder, PE500x750 jaw crusher, CS75 cone crusher, VSI7611 sand making machine, Vibrating screen, Sand recycling machine, Belt conveyor. |

Raw materials

| Limestone, Granite, Basalt, Quartz, River stone etc. |

Feed Size

| Less than 425mm |

Finished product

| Fine sand 0.25-0.35mm, medium sand 0.35-0.5mm, coarse sand 0.5mm. |

Capacity

| 50-100t/h |

Application

| In sand quarry, mine, construction site, highway, road and bridge construction, concrete mixing station, water conservancy and hydropower, chemical industry and other industries. |

Advantages

| High production efficiency and low operating cost; Multi-functions and Flexible application; Good shape of finished sand and fineness is adjustable. |

1. Complete crushing and screening plant is consisting of one or several crushing and screening units based on the customers' needs.

2. This series of plant is used to crush rocks in the industries such as road construction, building construction, construction materials, water and electricity and civil building etc working with commercial concrete, dry mixed mortar and mixing plant.

3. Core equipment for manufactured sand production line is sand making machine such as vsi crusher, vsi5x crusher etc.

4. It is suitable for crushing high quality of basalt, diabase, granite, river gravel, limestone and other hard or medium hard rocks.

5. High production efficiency, regular end product granularity, good grain cubical sand, and low powder content.

Save Time! Get A Detailed Quotation Quickly.