Calcium carbonate is an inorganic compound that is the main component of limestone and calcite. It has types of heavy calcium carbonate and light calcium carbonate. Heavy calcium carbonate and light calcium carbonate are different in particle size, crystal shape, and interface properties. The characteristics are also very different. Calcium carbonate is usually used as a filler, artificial floor tiles, rubber, plastics, paper making, coatings, paints, inks, cables, construction supplies, food, medicine, textiles, feed, toothpaste, etc

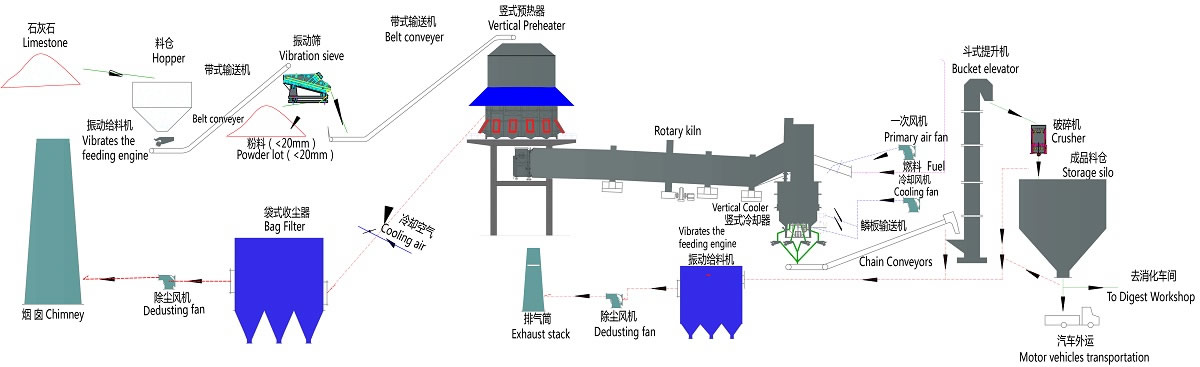

Heavy calcium carbonate production process includes:

Firstly, the raw material including calcite, limestone, chalk, shells, etc. transported from the quarry are selected by hand to remove the gangue; then the stones are crushed with a stone crusher, and then feed crushed material to HGM powder grinding mill to obtain ultra fine powder. Finally Use a classifier to classify the milled powder, and the powder that meets the particle size requirements is packed into the warehouse as a product, otherwise return to the calcium carbonate powder mill for regrinding.

HGM series calcium carbonate grinding mill machine

It is mainly suitable for ultra-fine powder processing of non-flammable and explosive brittle materials with medium and low hardness, Mohs hardness ≤ 6, such as calcite, chalk, limestone, dolomite, carbon black, Kaolin, bentonite, talc, mica, diatomite, barite, gypsum. It can be adjusted freely between 325-3000 meshes after being processed by HGM grinding mill.

| Equipment list | hammer crusher, bucket elevator, storage bin, vibrating feeder, HGM ring roller mill, frequency conversion classifier, double cyclone powder collector, pulse dust removal system, high-pressure fan, air compressor, electrical control system. |

| Raw materials | Limestone,calcium carbonate, calcite etc |

| Mohz hardness | 3-6 |

| Feeding size | <20mm |

| Capacity | 0.5-6tph (Zhongcheng provides professional solution for different capacity requirement) |

| Output Size | 325-3000mesh |

| Application | used as a filler, artificial floor tiles, rubber, plastics, paper making, coatings, paints, inks, cables, construction supplies, food, medicine, textiles, feed, toothpaste, etc. |

1. High efficiency and energy saving

In the case of the same finished product fineness and motor power, the output of this calcium carbonate mill is more than double that of jet mill, stirring mill and ball mill.

2. Long service life of wearing parts

The grinding roller and grinding ring of the calcium carbonate mill are forged from special materials, which greatly improves the utilization degree.

3. High safety and reliability

Calcium carbonate mill has no rolling bearings and no screws in the grinding chamber, so there is no problem of easy damage of bearings and seals, and no problem of easy loosening of screws and damage to the machine.

4. High product fineness

The fineness of calcium carbonate processed by calcium carbonate mill can reach D97≤5μm at one time.

5. Environmentally friendly and clean

The pulse dust collector in HGM grinding plant is used to capture dust, and the muffler is used to reduce noise, which is environmentally friendly and clean.

Save Time! Get A Detailed Quotation Quickly.