Mobile Crushing and Screening machine is high-efficiency and modular stone crusher plant. It can work by single machine, and also can it combine with other several machines to be a plant. It is widely used to stone process such as limestone, granite, quartz, gold ore etc

1.The mobile crushing and screening machine sonsist of"feeder + jaw crusher + cone crusher + vibrating screen",it can crush various stone materials and the finished product size can be kept within 0-40mm stably. It is mainly used for the production of aggregates , or secondary crushing stage of artificial sand. The cone crusher has feature of lower cost and large output for processing hard rock, and it possess long service life and few failures.

2. The mobile crushing and screening integrated machine consist of "feeder + jaw crusher + impact crusher + vibrating screen",it has two functions of two-stage crushing and sand making simultaneously. The vibrating screen assists in sorting sand and gravel. It can handle most stone raw materials in the mining industry, final products size can be controlled within 0-40mm.The sand grains are standard , the overall finished product quality is high, production process is efficiency.

3. The mobile crushing and screening integrated machine consist of "feeder + heavy hammer crusher + vibrating screen" has uniform particle size, good grain shape, and high quality. If utilizing the heavy hammer as the primary crushing machine, the processing capacity will be stronger, and feeding raw materials with larger particle size can be accepted, moreover the production cost will be lower.

4. The mobile crushing and screening machine consist of "sand making machine + vibrating screen" is a special combination for sand making. This combination can be used for sand making by itself . While If the particle size of raw material is far too large, it could combine with mobile jaw crusher or mobile cone crusher, the finished sand can meet the high-quality construction sand standard.

Primary and secondary crushing and screening machines are combined onto one carbody.

Flexible configuration. Various models can quickly combine with other models to meet the different needs of production.

Saving transportation cost of raw material.

Reasonable bearing structure and fast installation.

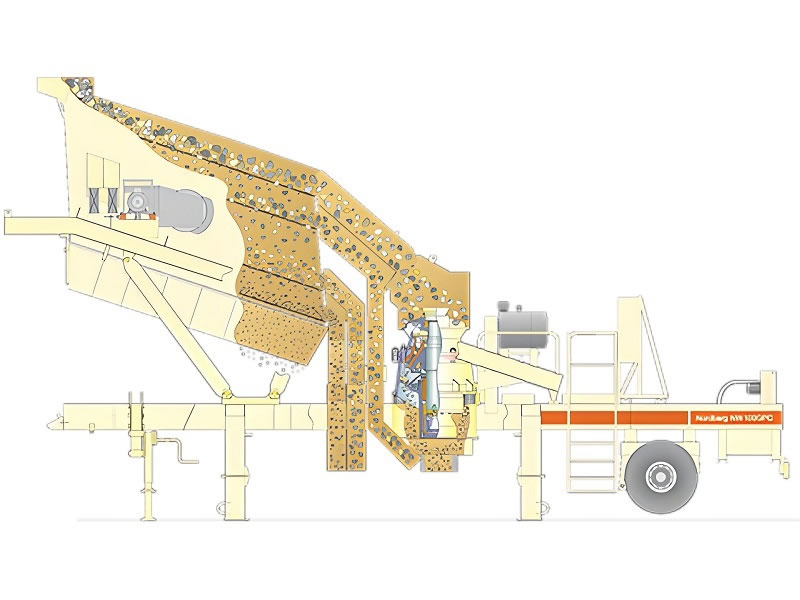

Mobile crushing plant is a kind of wheel type mobile stone crusher plant. It mount vibrating feeder, jaw crusher, cone / impact crusher, vibrating screen on one truck body to crush and screen gravels automatically. This four-in-one crushing plant is reasonable circular crushing system, it crushs stone in higher efficiency. When mobile stone crusher plant works, material by the feeded into jaw crusher by vibrating feeder. After primary crushing by jaw crusher, the stone be transmit to vibrating screen by main belt conveyor. During screening, the first layer unqualified material be transmited into secondary crusher to process. The rest qualified materials from other layers are discharged to different finished material area respectively based on their different sizes . The output from secondary crusher is conveyed to main belt conveyor for screening too. Thus, the material is in the circulation system of crushing-screening-crushing. The finished material could meet the final demand greatly.

| Technical Data//Model | MF1010E46 | MB900E57 |

| Transportation size (mm) | 14700x2400x4150 | 17000x2500x4300 |

| Weight(t) | 40 | 45 |

| Vibrating feeder | ZSW8530 | ZSW8530 |

| Crusher 1 | PE400x600 | PE500x750 |

| Crusher2 | PF1010 | PYB900 |

| Vibrating screen | 3YK1548 | 3YK1860 |

| Belt conveyer above screen | B500x8m | B500x8m |

| Belt conveyer under screen | B500x8m | B500x8m |

| Main belt conveyer | B650x11m | B650x11m |

| Side belt conveyer | B500x16m | B500x16m |

| Electric control (standard) | control box + control panel | control box + control panel |

| Support leg (standard) | 6 | 6 |

*The output will vary according to different materials, feed particle size and other factors.

Save Time! Get A Detailed Quotation Quickly.