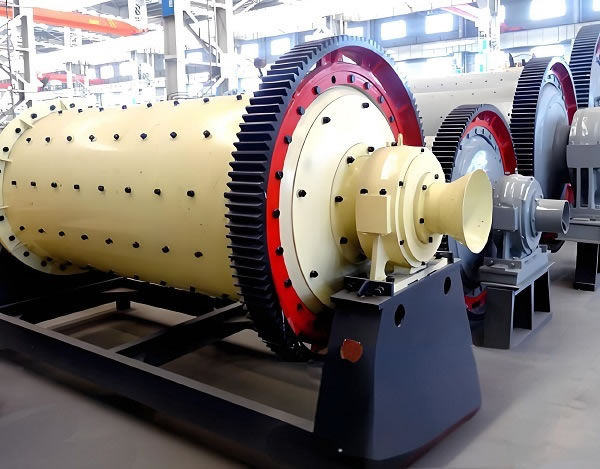

Cement mill is a kind of grinding ball mill to grind materials into fine powder. It is used to grind cement, limestone, gypsum, flay ash, clinker, bauxite etc. The complete cement mill plant is equipped with ball mill, bucket elevator, air classiffier...

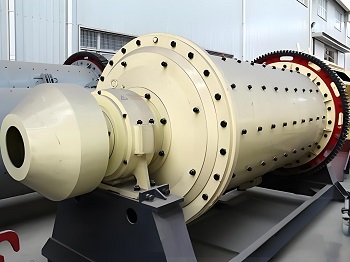

1.Dry ball mill is suitable for all kinds of metal ore, non-metal ore, including water will react to materials, such as cement, marble and other building stones, or require to be stored and sold in the form of powder products.

2.In addition, if the plant is located in the dry area with scarce water resources, dry ball mill is a good choice to save water.

3.Dry ball mill has strong adaptability to grind various materials, continuous production, easy to adjust the material fineness .

4.Dry ball mil can be used for open flow grinding system, and also suitable for circulating flow grinding system formed with air classifier.

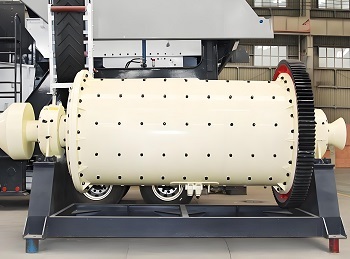

Dry type Ball mill is widely used in cement, silicate, new construction material, refractory material, chemical fertilizer, ferrous metal, non-ferrous metal and ceramics.

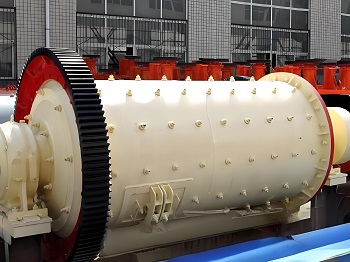

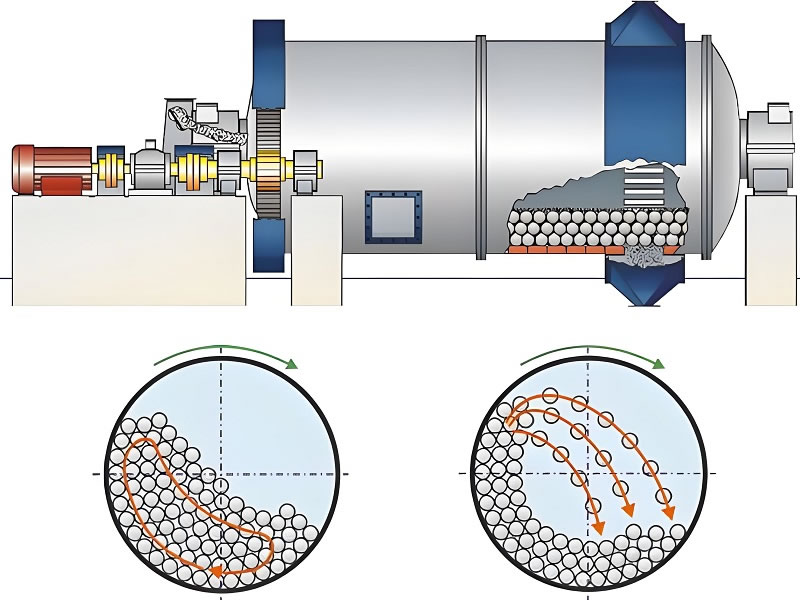

It could add partition panel in ball mill cylinder. After rough grinding in 1st chamber , by partition plate, the material will enter 2nd chamber for fine grinding.

The dry grinding needs dry materials, so it can't add water or other liquids during the dry milling process.

The ball mill could be equipped with steel lining plate, high aluminum porcelain lining plate or rubber lining plate to meet different requirement.

The materials are uniformly fed into the first chamber of cementball mill by the feeding device through the feeding hollow shaft. There is a stepped or corrugated liner plate and some steel balls of different specifications in the chamber. The impact force of steel balls falling will have a grinding effect on the material. After the kibbling in the first chamber, the materials will enter the second chamber through the monolayer partition board, which is inlaid with a flat liner plate and contains steel balls to further grind the materials. After that, the powder will be discharged through the discharge device.

| Model | Cylinder Rotating Speed (r/min) | Ball weight (t) | Feeding Size (mm) | Discharging Size (mm) | Capacity (t/h) | Power (kw) |

| Ф900×1800 | 38 | 1.5 | ≤20 | 0.075-0.89 | 0.65-2 | 18.5 |

| Ф900×3000 | 38 | 2.7 | ≤20 | 0.075-0.89 | 1.1-3.5 | 22 |

| Ф1200×2400 | 35 | 4.6 | ≤25 | 0.075-0.6 | 1.6-5.8 | 37 |

| Ф1200×3000 | 36 | 3.5 | ≤25 | 0.074-0.4 | 1.6-5 | 37 |

| Ф1200×4500 | 35 | 5.5 | ≤25 | 0.074-0.4 | 1.6-5.8 | 55 |

| Ф1500×3000 | 29 | 9 | ≤25 | 0.074-0.4 | 2-7 | 75 |

| Ф1500×4500 | 27 | 11 | ≤25 | 0.074-0.4 | 3-6 | 110 |

| Ф1500×5700 | 29 | 17 | ≤25 | 0.074-0.4 | 3.5-6 | 110-130 |

| Ф1830×4500 | 25.4 | 15 | ≤25 | 0.074-0.4 | 4.5-12 | 155 |

| Ф1830×6400 | 24.1 | 21 | ≤25 | 0.074-0.4 | 6.5-15 | 210 |

| Ф1830×7000 | 24.1 | 23 | ≤25 | 0.074-0.4 | 7.5-17 | 245 |

| Ф2100×4500 | 23.7 | 24 | ≤25 | 0.074-0.4 | 8-43 | 245 |

| Ф2100×7000 | 23.7 | 26 | ≤25 | 0.074-0.4 | 8-48 | 280 |

| Ф2200×4500 | 21.5 | 27 | ≤25 | 0.074-0.4 | 9-45 | 280 |

| Ф2200×6500 | 21.7 | 35 | ≤25 | 0.074-0.4 | 14-26 | 380 |

| Ф2200×7000 | 21.7 | 35 | ≤25 | 0.074-0.4 | 15-28 | 380 |

| Ф2400×3000 | 21 | 23 | ≤25 | 0.074-0.4 | 30-50 | 245 |

| Ф2400×4500 | 21 | 30 | ≤25 | 0.074-0.4 | 40-60 | 320 |

| Ф2700×3600 | 20.7 | 40 | ≤25 | 0.074-0.4 | 45-80 | 430 |

| Ф2700×4500 | 20.7 | 48 | ≤25 | 0.074-0.4 | 50-90 | 430 |

| Ф2700×13000 | 20.7 | 60 | ≤25 | 0.074-0.4 | 50-90 | 630 |

| Ф3200×4500 | 18 | 65 | ≤25 | 0.074-0.4 | -- | 800 |

*The output will vary according to different materials, feed particle size and other factors.

Save Time! Get A Detailed Quotation Quickly.