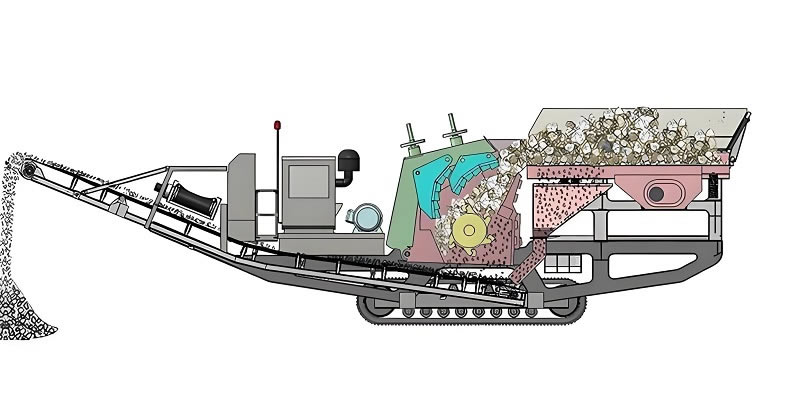

Mobile jaw crusher is heavy duty crushers to crushing hard stone in mining,mineral,construction waste recycling fields. Mobile stone crusher integrates feeder, jaw crusher, belt conveyor, control system to solve site infrastructure effectively.

1.When choosing a mobile crusher machine, it should meet the processing capacity requirements of the production line, so as to avoid the stacking problem caused by excess raw materials, and also improve efficiency. At the same time, the characteristics of the material should also be considered. If the particle size of the input material is uneven, a feeder with a pre-screening function can be selected; if the material has high moisture content and high hardness, it will increase the difficulty of crushing, Therefore, mobile crushing machine with theoretical capacity higher than that of production line should be selected.

2. Consider the compatibility with existing devices. For the quarry, the production line equipment mainly includes: electric shovel, truck and other feeding equipment, as well as sand making machine and other process equipment, and the production capacity of the mobile crusher should match it, in order to avoid the waste of stone. For tire-type mobile crusher plant, the traction and mobility of the existing truck should also be considered. If the two do not match, it will affect the use and will also bring a waste of existing resources.

3.Consider the movement period. If the crushing equipment needs to move flexibly, the crawler mobile crusher is a better choice; if it does not need frequent transitions, then you can choose semi-mobile or tire-type, which can not only meet the mobile needs, but also reduce equipment purchase costs.

Mobile stone crusher is incorporated design. Feeder and vibrating screen integrated with jaw crusher, cone crusher, impact crusher, hammer crusher etc.

With support legs on truck,quick to set-up. The mobile stone crusher plant supporting legs height can be adjustable, adopt hydraulic controling parts.

Truck mounted and easy to move. Due to strong structure, mobile stone crusher can be transported on highway and moved between different crushing sites.

Mobile Crusher Plant can be used by single operator, feed can be done by truck, loader or excavator. Closed Circuit stone crushing system till to get desired size of product.

A complete mobile stone crushing and screening plant which consists of raw material bins which located on one or more trailers, vibrating feeders, primary jaw crushers, multi-layer vibrating screens, secondary crushers, fine crushers, mobile belt conveyors, sand washers, electric control systems and etc. Mobile stone crusher plant incorporates all the equipment together on one truck, which has high chassis, narrower body compared with other trucks. Materials are fed to vibrating feeder by loader, then evenly go into jaw crusher for primarily crushing. The final aggregates will be tranport into piles by belt conveyor. Mobile jaw crusher could be used a singel crushing unit or work with mobile impact crusher or mobile cone crusher plant.

| Model | SMC600 | SMC750 | SMC900 | SMC1060 | SMC1200 | SMC1300PEX |

| Transport size | ||||||

| Length(mm) | 8600 | 9600 | 11097 | 13300 | 15800 | 9460 |

| Width(mm) | 2520 | 2520 | 3759 | 2900 | 2900 | 2743 |

| Height(mm) | 3770 | 3500 | 3500 | 4440 | 4500 | 3988 |

| Alex weight(kg) | 10121 | 14500 | 21380 | 38430 | 64000 | 14730 |

| King pin weight(kg) | 5118 | 7500 | 10890 | 19450 | 34000 | 10490 |

| Jaw crusher | ||||||

| Model | PE | PE | PE | PE | PE | PEX |

| Feed opening(mm) | 400X600 | 500X750 | 600X900 | 750X1060 | 900X1200 | 300X1300 |

| Discharging hole setting range(mm) | 40-100 | 50-100 | 65-180 | 80-180 | 95-225 | 20-90 |

| Capacity(t/h) | 15-60 | 40-110 | 90-180 | 110-380 | 220-450 | 30-105 |

| Feeder | ||||||

| Feed hopper volume | 3 | 4 | 7 | 10 | 10 | 3 |

| Hopper width | 2200 | 2500 | 3000 | 3000 | 3000 | 2200 |

| Model | ZSW6520 | ZSW8530 | ZSW9638 | ZSW1142 | ZSW1349 | ZSW8530 |

| Belt conveyor | ||||||

| Model | B650X6 | B800X7 | B1000X8 | B1000X11 | B1200X13 | B1000X7 |

*The output will vary according to different materials, feed particle size and other factors.

Save Time! Get A Detailed Quotation Quickly.