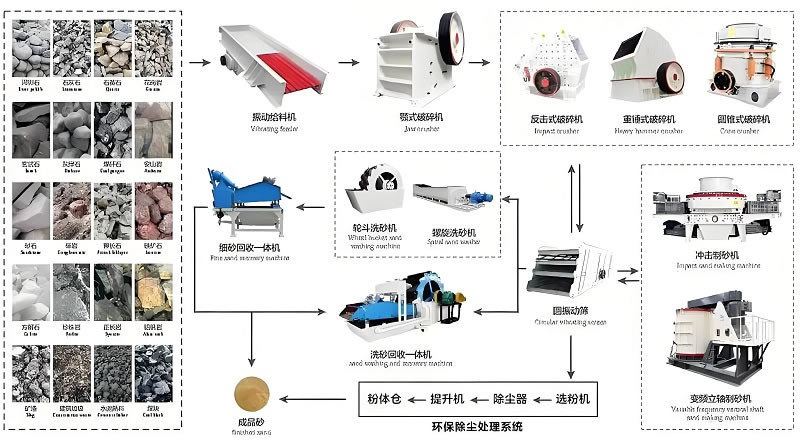

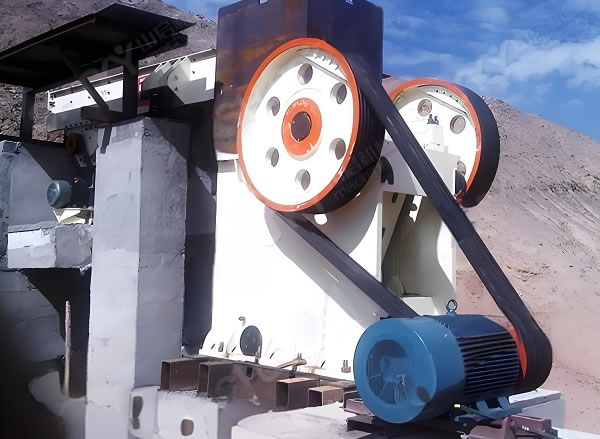

This 100 t/h Stone crusher plant 100 tph is including Hopper, vibrating feeder ZSW850x3000, jaw crusher PE500x750, impact crusher PF1214, vibrating screen, belt conveyor. It is primarily involved in the manufacture of aggregates (coarse aggregates, crusher run, rock sand, fine aggregates) from limestone, quartz,basalt and so on. Coarse aggregates are usually used in ready mix concrete and asphaltic concrete. Crusher run is used for the bases and sub-bases for road making. Fine aggregates are used for the production of concrete and plastering.

Equipment configuration

| Hopper, ZSW960x3800 vibrating feeder, PE600x900 jaw crusher, PF1214impact crusher, Vibrating screen, Belt conveyor. |

Raw materials

| Limestone, Granite, Basalt, Quartz, River stone etc. |

Feed Size

| Less than 350mm |

Capacity

| 40-60t/h |

Finished product

| 3-100mm |

Application

| produce aggregate of limestone, granite, basalt, river stone, marble, iron ore, dolomite, quartz, slag etc, which is widely applied for hydropower, construction, highway, railway, airport runway, civil engineering projects and etc. |

Advantages

| High production efficiency and low operating cost; Large output, uniform particle size of finished stones and good grain shape, which meets the requirements of national high-speed materials. |

1. The complete stone production plant is a two-stage crushing plant. It could produce sand & gravels with various granularities of limestone, granite, dolomite, quartz etc.

2. The final size is 0-6mm(0-1/4' ), 6-12mm(1/4’-1/2’), 12-25mm( 1/2’-1’)(or other sizes according to your need) as aggregate for construction. It is suitable for application in hydropower, construction, highway, railway, airport runway, civil engineering projects and etc.

3. High degree of automatic operation. The whole crushing plant requires sevral workers for machine starting and stopping, routine maintenance.

4. High production efficiency, low cost, regular end product granularity, good grain shape, and low powder content. Adopting high advanced control system to ensure security and reliable operation of the entire stone crushing plant.

5. We also design and provide stone crusher plant with capacity 50 t/h, 100 t/h, 150 t/h, 200 t/h, 300 tph, 400 t/h, 500 t/h, 800 t/h, 1000 t/h. The solution with flowchart and price could be sent for free.

Save Time! Get A Detailed Quotation Quickly.