As an advanced crushing equipment widely used in mining, construction, chemical and other industries, the European version of the jaw crusher has become a key equipment in the field of material processing with its excellent performance and unique design. The European version of the jaw crusher has the following characteristics:

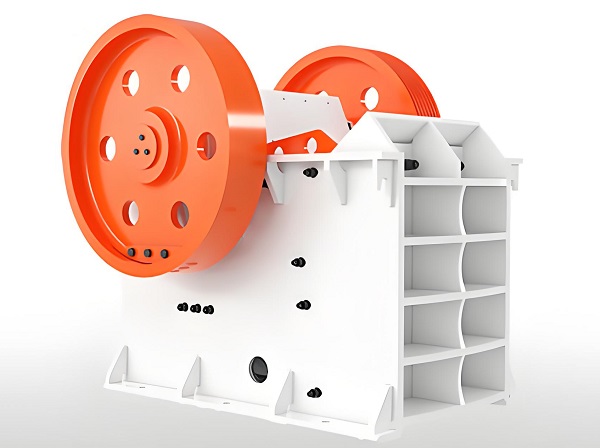

European jaw crusher

1. Structural design

Sturdy frame: It adopts a non-welded detachable frame, which is mostly made of integral cast steel. For example, the frame side panels and front wall panels and rear crossbeams of the CJ series European version of the jaw crusher are connected by cylinders. Compared with the traditional welded frame, it is more convenient to transport and install, and has higher strength and stability.

Advanced movable jaw assembly: The movable jaw assembly is composed of high-quality cast steel parts and is driven by two large cast steel flywheels. The heavy eccentric shaft is processed by forging billets, which makes the equipment have extraordinary reliability and more durable.

Integral cast steel bearing seat: It can ensure full cooperation with the crusher frame, greatly enhance the radial strength of the bearing seat, and has stronger stability and load-bearing capacity than the split bearing seat.

Symmetrical "V"-shaped crushing chamber: The actual feed opening width is consistent with the nominal feed opening width, which can increase the feed opening width, so that the material can enter the crushing chamber more smoothly, while optimizing the material flow path and improving the crushing efficiency.

Wedge-type discharge port adjustment device: Compared with the old-fashioned gasket adjustment method, this device makes the adjustment of the discharge port simpler, safer and faster, and can easily adjust the discharge particle size according to production needs.

2. Working principle

The motor drives the belt and pulley to swing the movable jaw forward and backward and up and down through the eccentric shaft. When the movable jaw pushes the movable jaw plate to move toward the fixed jaw plate, the material is crushed or split; when the movable jaw and the movable jaw plate retreat under the action of the eccentric shaft and spring, the previously crushed or split material is discharged from the lower discharge port of the jaw plate. As the motor rotates continuously, the movable jaw of the crusher periodically crushes and discharges the material to achieve batch production.

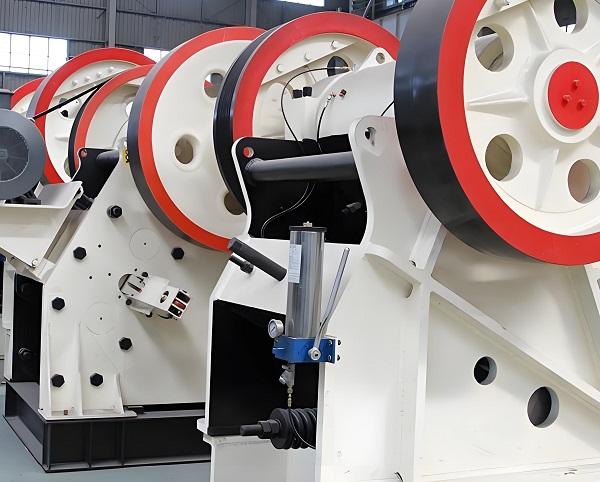

European jaw crusher

3. Performance characteristics

Manufacturing process and materials: World-class manufacturing process is adopted, and the most advanced manufacturing materials, such as high manganese steel, are selected, so that the key components of the equipment, such as jaw plates, have good wear resistance, which prolongs the service life of the equipment.

High crushing efficiency: The optimized crushing chamber type and motion parameters enable the material to be more fully crushed in the crushing chamber, with a large crushing ratio, which can effectively crush large pieces of material into smaller particles, and has a large production capacity. Compared with ordinary jaw crushers, the output can be increased by 100-150 tons.

Uniform discharge particle size: The wedge-type discharge port adjustment device can accurately control the size of the discharge port, ensure the uniformity of the discharge particle size, and better meet the requirements of different users for product particle size.

Convenient lubrication and maintenance: The oil lubrication system is adopted, which has greater fluidity and higher lubrication efficiency than the butter lubrication of ordinary jaw crushers, and is not easy to leak and oxidize, which can effectively reduce the maintenance cost and maintenance workload of the equipment. At the same time, the overall structural design of the equipment is convenient for inspection and maintenance, reducing downtime.

Significant energy-saving effect: For example, the CX series European version jaw crusher can reduce energy consumption by 10%+ through optimized stroke design, which can save a lot of energy costs in long-term operation.

European jaw crusher

4. Application fields

Mining industry: used for coarse and medium crushing of various ores, such as iron ore, copper ore, gold ore, etc., and can crush the mined large pieces of ore into a particle size suitable for subsequent processing.

Construction industry: can crush limestone, granite, basalt and other stones to produce stone, stone powder and other materials for construction, which are used in infrastructure construction such as roads, bridges, and houses.

Chemical industry: crush some chemical raw materials, such as gypsum and coal, to meet the particle size requirements in the chemical production process.

Metallurgical industry: in the metallurgical process, it is used to crush various metal ores and waste slag, etc., to provide raw materials of suitable particle size for subsequent smelting processes.

Overview of the characteristics of the European version jaw crusher: In terms of working principle, the European version jaw crusher drives the pulley through the motor to drive the eccentric shaft to make the movable jaw swing periodically. During the swinging process, the movable jaw squeezes and crushes the material, and then discharges the crushed material. In terms of structural design, the European version of the jaw crusher adopts a non-welded detachable frame made of high-strength integral cast steel, which not only ensures the stability of the equipment during operation, but also greatly reduces the difficulty of transportation and installation. The movable jaw assembly also uses high-quality cast steel parts, with a heavy-duty eccentric shaft and an integral cast steel bearing seat, which significantly improves the load-bearing capacity and reliability of the equipment.

The excellent performance of the European version of the jaw crusher is reflected in many aspects: the use of high-end manufacturing technology and wear-resistant materials greatly extends the service life of the equipment; the optimized crushing cavity and motion parameters greatly improve its crushing efficiency and make the discharge particle size more uniform; the advanced oil lubrication system not only improves the lubrication efficiency, but also reduces maintenance costs and workload. In addition, its energy-saving effect is significant, which can effectively reduce long-term operating costs. Whether it is coarse crushing or medium crushing, the European version of the jaw crusher can efficiently handle all kinds of ores and stones, providing reliable support for material processing in various industries.

Save Time! Get A Detailed Quotation Quickly.