Raymond mill is a type of grinder used to grind materials into fine powder.Applied material: limestone,calcite, gypsum,talc,dolomite,calcium carbonate materials with Moh's< 6 and humidity < 6%.

1. Raymond roller mill is an efficient closed-circuit circulating powder making equipment. Compared with the ball mill, it has the advantages of high efficiency, low power consumption, small footprint, small investment and no environmental pollution.

2. Raymond grinding mill is vertical structure with small coverage. From raw material rough processing to transportation to powder and final packaging, it can be an independent powder production system.

3.For Raymond mill, its application is mainly in small and medium-sized mines, chemicals, building materials, metallurgy, refractory materials, pharmaceuticals, cement, etc., Zhongcheng Machinery could provide great help for the processing of different materials in these industries.

Stable Raymond grinding mill is an independent milling system from primary material to final powder. It covers small area with solid structure.

Fineness of finished powder is even, and qualified screening rate could reach 99%, which is difficult to reach for other milling equipment.

The transmission device adopts a sealed gear box and pulley, with smooth transmission and reliable operation.

The whole powder grinding process is completed in the closed air circulation system to reduce environmental pollution.

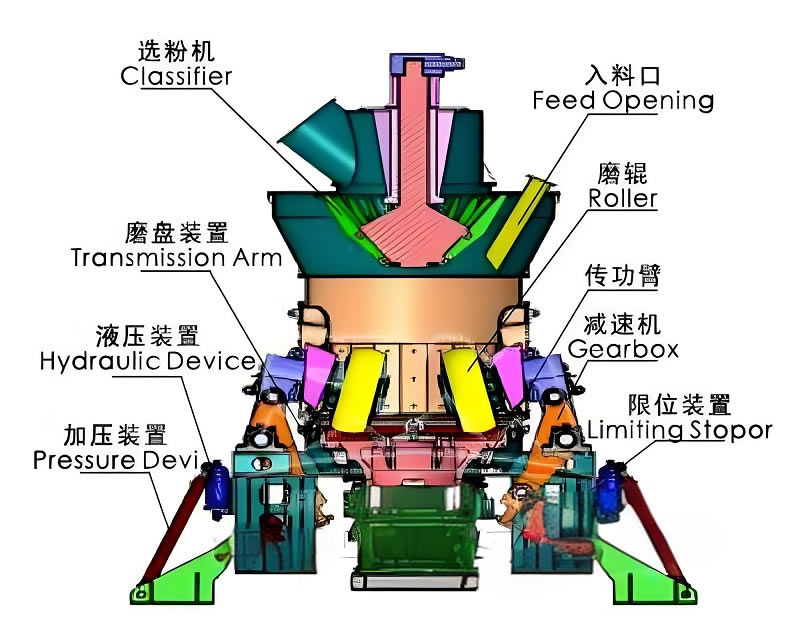

Raymond mill is mainly composed of main grinding machine, fineness analysis machine, blower, cyclone, bag dust collector and connecting air duct. According to user needs, Zhongcheng Machinery could supply jaw crusher, bucket elevator, vibrating feeder, electric control cabinet and other auxiliary equipment. How does raymond mill machine work? Large rocks are crushed by jaw crusher machine to 0-20mm, and carried by bucket elevator to storage hopper. The crushed rocks by jaw crusher to the needed size are fed into the storage hopper and then they are fed into main raymond mill grinding chamber evenly by vibrating feeder. The grinded materials are blown into analyzer by blower for classification. With the function of impellers and airflow of the fan, materials without meeting fineness are fallen into grinding chamber for grinding again. Qualified powder are blown into a cyclone with airflow through pipelines for collection. The powder from a discharging device is the finished product to packing machine. Separated airflow is back to blower through return duct on the top of the cyclone powder collector.The entire airflow system of this machine is closed and circulating, and it circulates under the condition of positive and negative pressure.

| Model | Roller (pcs) | Roll Dia. (mm) | Roll Ring Size (mm) | Max. Input Size (mm) | Output Size (mm) | Capacity t/h | Power (Kw) | Dimension (mm) |

| 3R2115 | 3 | 210*150 | 630*150 | 15 | 0.125-0.044 | 0.4-1 | 15 | 3500*3300*4500 |

| 3R2615 | 3 | 260*150 | 780*150 | 20 | 0.125-0.044 | 0.5-2 | 18.5 | 4650*3600*5100 |

| 3R2715 | 3 | 270*150 | 830*150 | 20 | 0.125-0.044 | 0.8-3 | 22 | 4700*3600*5100 |

| 4R3016 | 4 | 300*160 | 890*160 | 25 | 0.125-0.044 | 1-4 | 30 | 5400*4100*5200 |

| 4R3216 | 4 | 320*160 | 970*160 | 25 | 0.125*0.044 | 1.8-4.5 | 37 | 7100*5900*7900 |

| 5R4119 | 5 | 410*190 | 1270*190 | 30 | 0.613-0.044 | 2.5-9.5 | 75 | 9200*7250*9700 |

*The output will vary according to different materials, feed particle size and other factors.

Save Time! Get A Detailed Quotation Quickly.