1. Customers have requirements for 0-5mm finished sand output. In the selection of sand making machine , according to the proportion of raw sandstone to calculate the final production to determine the appropriate model.

2. There are two sources of sand making machine feeding. One is the raw material. Less than 40mm could direct goes to VSI sand making machine. The second part is according to the cone crusher output, check which finished product demand is small, then some material after cone crusher will be appropriated into VSI sand making machine.

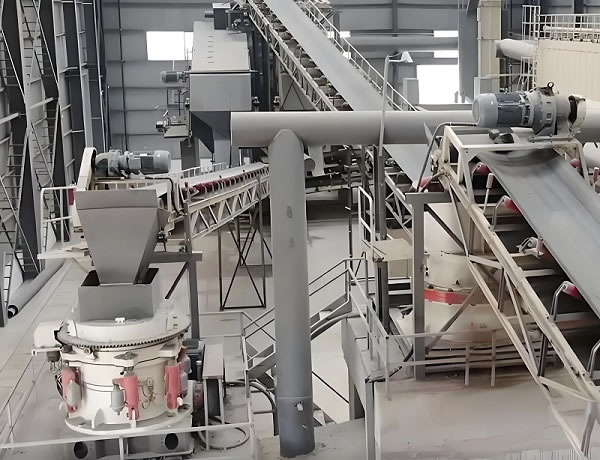

3. The total set up for limestone crushing plant is high efficienty and flexible to meet different demamds.

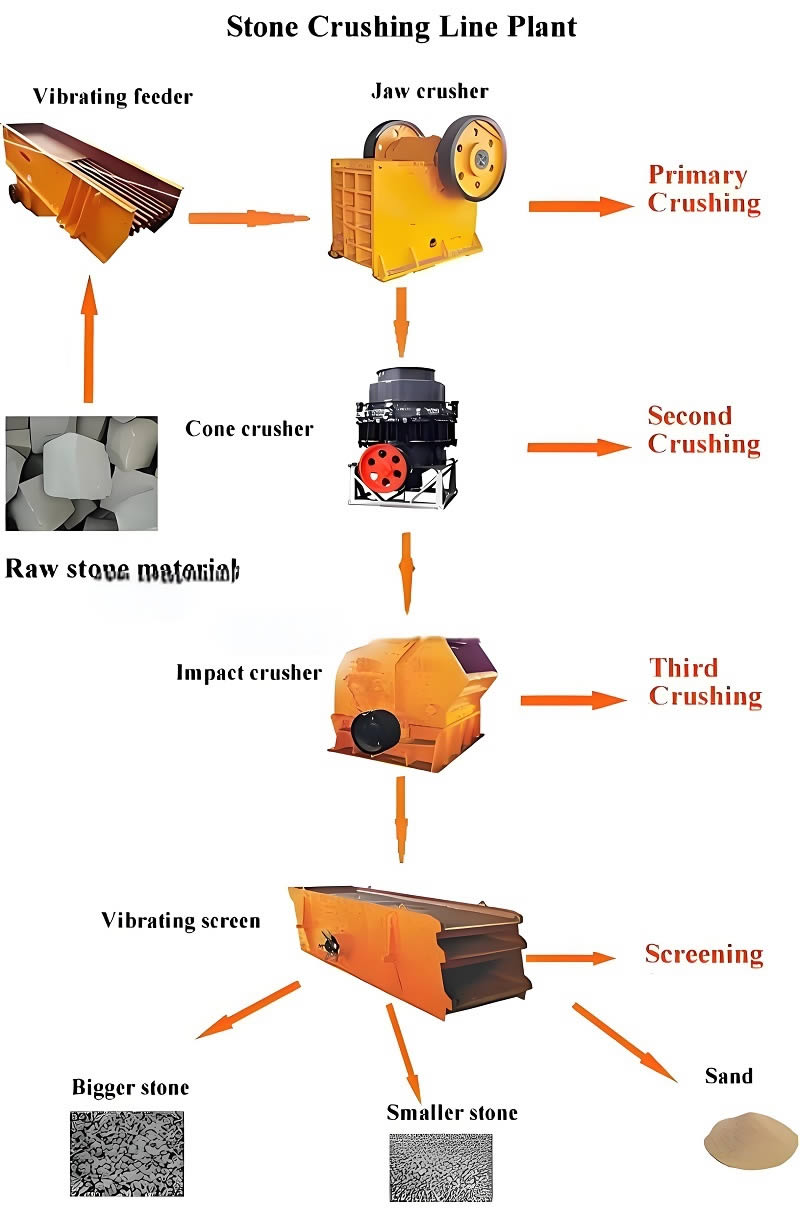

1. Feeding equipment, like vibration feeder or plate type feeder: These machines feed the jaw crusher with the rocks and stones to be crushed.

2. Crushing equipment: These are the machines where the rocks and stones are crushed. Generally jaw crushers and Gyratory crushers are used for primary crushing, while impact crusher, Symons cone crusher, sand crusher are used for secondary crushing and tertiary crushing.

3. Vibrating Screen: These machines are used to separate the different sizes of the material obtained by the crushers.

4. Belt Conveyor: They are used for transportation of the material from one machine to another during different phases of process.

5. Central electric control system: Control and monitor the operation of the entire system.

Save Time! Get A Detailed Quotation Quickly.