PCX fine crusher is kind of hammer crusher to crush limestone, cement, quartz etc. Due to more wear-resistant hammerhead and larger capacity, it is used to making artifical sand and gravels too.

Energy saving and consumption reduction.The structural design principle of PCX fine crusher is composed of "stone beating stone" coarse crushing cavity, fine crushing cavity, adjustable counter plate and discharging grates. It has the advantages of high output and stable operation.

High output rate. Fine crusher could control the material discharging granularity due to the grates, so the required material granularity can reach more than 95 percent, to achieve a more ideal material granularity control, screening. It has changed the problems of poor grain size and irregular grain shape of finished products.

Discharging size adjustable.The discharging particle size of fine crusher can be adjusted. And the adjustment plate can be turned over at both ends, simple operation, convenient adjustment, no jam, no block. It is a stable performance of crushing equipment.

High component performance. The hammer head of fine crusher can be used on all sides, with high utilization rate and high hardness.

High crushing efficiency: grate plate design, rigid hard extrusion crushing, making the fine crushing efficiency greatly improved.

Environmental and energy saving: high speed and fast operation , save electricity and reduce consumption.

Wear-resistant parts durable: more durable with wear-resistant parts material.

Low maintenance cost: compared with traditional pulverizer, energy saving is better, stable operation, maintenance cost is lower.

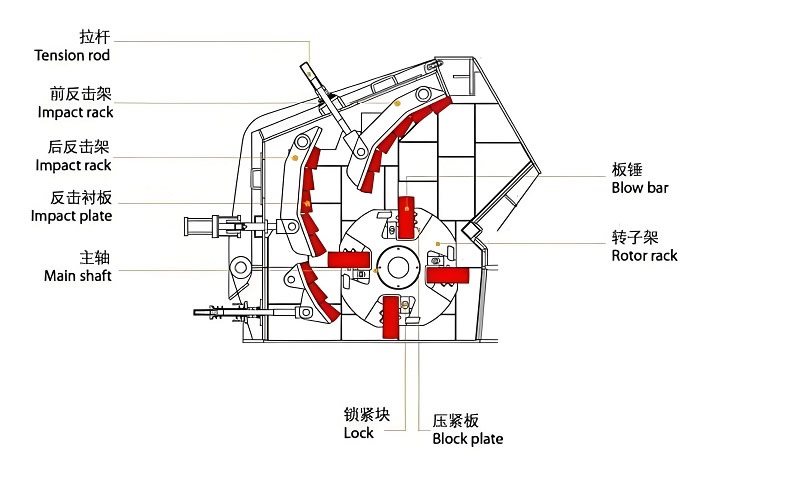

When PCX fine crusher works, the rotor keeps rotating in high speed driven by the motor. Hammers are installed on the rotor. When the materials get into the area which the hammer affects, under the high-speed impact effect by the hammer, they are thrown to the impact device above the rotor continuously. Then the materials are rebounded from the impact liner to the area where the hammer affects for being re-crushed. The materials no matter large or small are all crushed in the impact chamber repeatedly. This process will not stop until the materials are finally crushed into prospected size and discharge from the grate screen at the bottom.

| Model | Feeder Opening Size(mm) | Feeding Size(mm) | Output Size(mm) | Capacity of Cement(t/h) | Capacity of Limestone(t/h) | Motor Power(kw) |

| PCX-0804 | 400X185 | < 120 | < 3(85%) | 20-30 | 35-45 | 45 |

| PCX-0806 | 500X250 | < 180 | 35-40 | 45-45 | 55 | |

| PCX-0808 | 550X330 | 35-45 | 55-65 | 55 | ||

| PCX-1010 | 1000X350 | 45-55 | 65-75 | 75 | ||

| PCX-1210 | 1200X400 | 50-100 | 80-100 | 110 | ||

| PCX-1212 | 1200X450 | < 5(85%) | 90-110 | 100-110 | 132 | |

| PCX-1414 | 1500X500 | < 190 | 100-150 | 100-150 | 160 | |

| PCX-1616 | 1600X550 | 170-210 | 190-250 | 250 | ||

| PCX-1818 | 1800X800 | 250-270 | 280-310 | 315 |

*The output will vary according to different materials, feed particle size and other factors.

Save Time! Get A Detailed Quotation Quickly.