MTW raymond mill is the latest grinding machine. It is widely used to grind limestone, gypsum, marble, dolomite, kaolin, diatomite, silicate,slag,flyash etc.

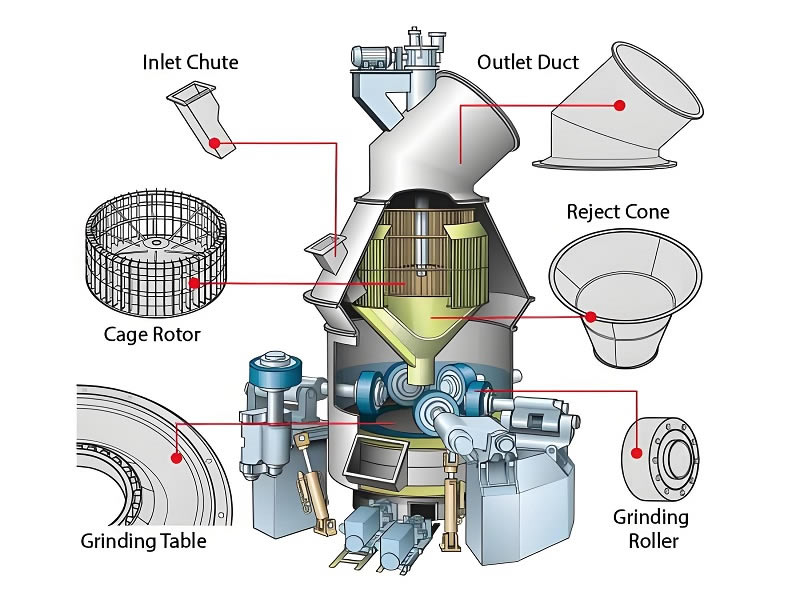

1. The integral transmission of bevel gear is adopted, so the transmission is stable and transmission chain is reduced. Also the transmission ratio is accurate and energy loss is greatly reduced. Performance of MFW grinding mill is significantly improved.

2. The frequency conversion type powder separator is adopted, and the isolation structure is adopted between the inner cylinder of the powder separator and the mixed air powder flow, which can effectively improve the efficiency and precision of powder selection.

3. Unique air self-circulation system, less dust discharge. Powder grinding mill plant can be equipped with pulse dust collector, high dust removal efficiency, low emission concentration, basically realize the dust-free operation of the workshop.

4. The output is large, and it is widely used in medium and large-scale processing of ultra-fine dry grinding powder such as limestone, calcium carbonate, lime calcium powder, talcum powder, barite, kaolin, bauxite, bentonite, calcite, and gypsum. And so on.

New type edge-replaceable shovel save cost.

Arc air channel reduces energy consumption and intelligent control ensures better operation.

frequency-control separator and cyclone powder collector ensure higher capacity.

Unique air recycling system and dust collector make clean environment.

Big lump materials are crushed to required size by jaw crusher, then it is elevated to buffering hopper through elevator. After that it is fed into the mill to grind between ring and rollers. The grinded particles move up with the air flow, those cannot pass the separator will fall down and be ground again, while others will be collected as finished product. Air flow passing through separator will go to the air blower for recycling, it's a closed system.

| Model | Roller Size (mm) | Grind Ring Size DxH(mm) | Main Roller Speed (r/min) | Max Feeding Size (mm) | Output Size (mm) | Capacity (t/h) | Power (Kw) | Overall Dimension (mm) |

| MTW110 | 360×210 | 1100×210 | 120 | 30 | 0.038-0.6 | 3-10 | 75 | 8425×8933×8642 |

| MTW138 | 460×260 | 1380×260 | 96 | 35 | 0.038-0.6 | 6-20 | 90 | 10920×9470×10227 |

| MTW175 | 520×300 | 1750×300 | 75 | 40 | 0.038-0.6 | 10-35 | 185 | 12195×9555×9916 |

| MTW215 | 640×340 | 2150×340 | 65 | 50 | 0.038-0.6 | 20-50 | 280 | 13922×9810×13226 |

*The output will vary according to different materials, feed particle size and other factors.

Save Time! Get A Detailed Quotation Quickly.