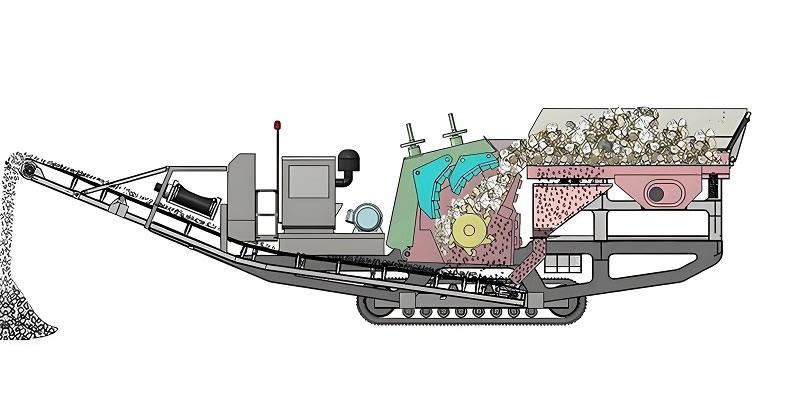

The tracked mobile crusher is a fully hydraulic driven tracked vehicle chassis mobile crushing and screening equipment , which produced by our company to meet market demand. The tracked mobile crushing station is mainly used for processing materials that often be required to move operation ,such as metallurgy, chemical industry, building materials, water and electricity, etc. Users can adopt various configuration forms according to the type, scale, and requirements of the processed raw materials.

1.The chassis adopts an all steel ship structure, with high strength and stronger adaptability to the work site.

2.High power walking motor with strong horsepower, safe and reliable.

3.Using well-known brand motors to achieve excellent performance of the power system, with low noise, energy-saving and other characteristics.

4.According to customer requirements, various levels of crushing and screening equipment can be allocated, and the entire machine is optimized to ensure quality.

5.Can be equipped with a generator set to meet the normal operation requirements of complex situations such as no electricity or power outage, ensuring continuous operation and reducing losses.

Tracked jaw crusher is used as an efficient primary crusher on tracks with a large feed opening provides outstanding crushing capacity.

Dual power mode – flexibility to power the plant either by external electric connection or by on-board diesel generator power pack unit (optional).

Heavy duty track unit with dual speed configuration. Easily remote control for walking.

This equipment is a mobile crushing and screening equipment developed independently by our company to meet market demand, which is a fully hydraulic driven tracked vehicle chassis. It adopts an integrated group operation method, eliminating complex installation operations and reducing material labor consumption.

The materials are uniformly conveyed to the jaw crusher by the feeder, and after the initial crushing by the jaw crusher, the materials are sent to the impact crusher for secondary crushing by the conveyor. The crushed materials are screened by the vibrating screen, and the materials that meet the crushing requirements are output by the conveyor. The materials that do not meet the requirements are again crushed by the impact crusher. The entire tracked jaw crusher and the impact mobile crushing station production line form a closed circuit system through the circular vibrating screen, achieving circular crushing of the materials. The finished materials are output by the conveyor for continuous crushing operations.

| Model | Feeder | Jaw Crusher | Main Discharge Belt | Side Discharge Belt | Capacity |

|---|---|---|---|---|---|

| YMC80 | G2D8035 | C80 | B800x9m | B500x3.8m | 80-125t/h |

| YMC96 | G2D9638 | C96 | B1000x12m | 100-250t/h | |

| YMC106 | G2D1142 | C106 | 160-360t/h | ||

| YMC116 | C116 | B1200x13m | 200-450t/h | ||

| YMC120 | G2D1242 | C120 | 300-520t/h |

*The output will vary according to different materials, feed particle size and other factors.

Save Time! Get A Detailed Quotation Quickly.