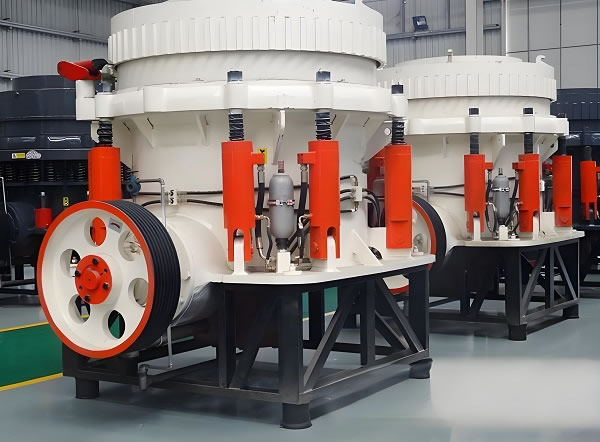

Symons cone crusher is also called compound stone cone crusher. It's semi hydraulic and semi spring cone crusher to crush mid-hard and above mid-hard ores and rocks efficiently. Symons crusher is popular stone crusher in aggregates production plant.

1. Through the optimized design of the cavity and the combination of reasonable speed and stroke, CS cone crusher can perform the most work under the same diameter of the moving cone. Therefore, compared with the same type of spring cone crusher, it has higher performance and production capacity.

2. Based on the principle of lamination crushing, the proportion of cubes in the crushed s tone product is significantly increased, the needle-like stones are reduced, and the particle size is more uniform.

3. When unbreakable materials enter cone crusher crushing chamber, high-performance alloy steel springs are used as advanced overload protection system, it can effectively protect machine safety.

4. The automatic control system adopts large-diameter main shaft, heavy-duty main frame and independent thin oil lubrication system to ensure that the equipment is durable and reliable in operation.

Hydraulic overload protection device helps to remove iron and reduce downtime. Thin oil lubrication station is outfitted with cooling system for better cooling performance.

Crushing cavities of standard or short head are changeable through different mantles and bowl liners for better meeting user’s needs.

Heavy-duty design and use of high-quality components with optimized wear parts keep the operating costs down.

Easy maintenance, and easy to operate. Laminated crushing process makes the final material in good grain shape.

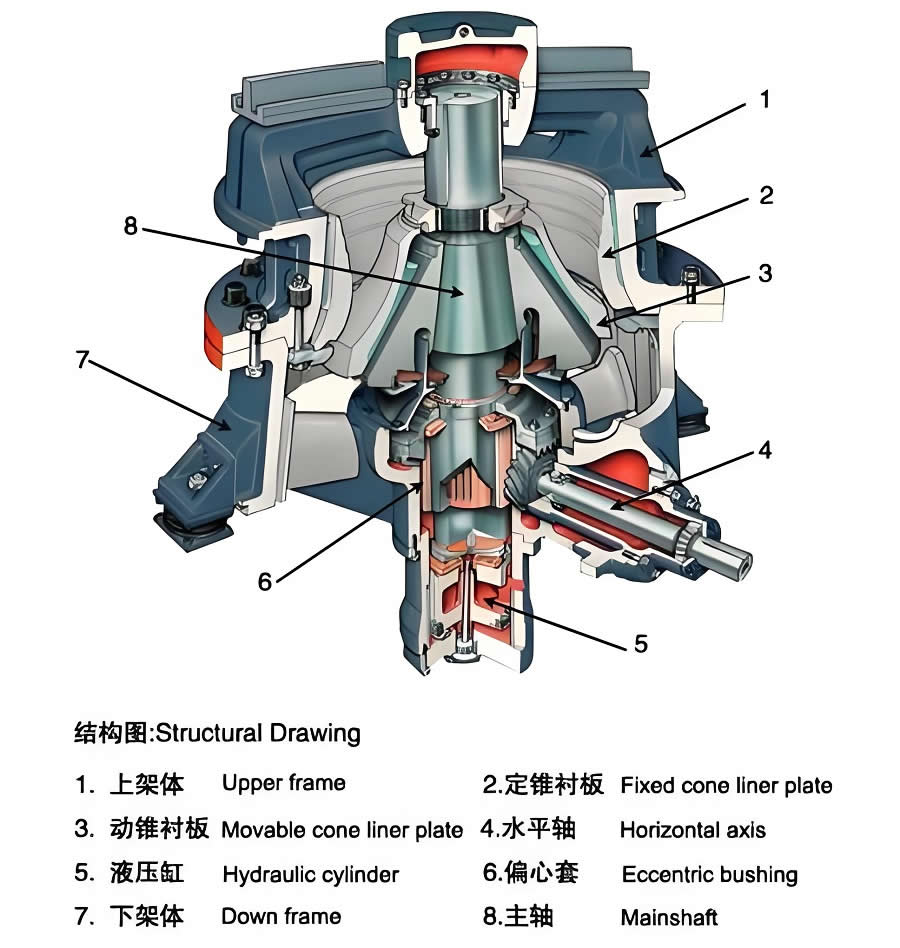

Symons Cone crusher is a compression type of stone crusher. The feeding rock is crushed by squeezing or compressing the feed material between a wear resistant mantle and a manganese concave or a bowl liner. The mantle is a moving part that gyrates in an eccentric motion though an eccentrically gyrating spindle.

When rock enters the top of the cone crusher, it is squeezed between the mantle and the bowl liner or concave, as the eccentric spindle rotates to cause the compression within the chamber. The material gets smaller as it moves down through the wear liner as the opening in the cavity gets tighter. Large pieces of ore are broken once, and then fall to a lower position where they are broken again. This process continues until the pieces are small enough to fall through the narrow opening at the bottom of the crusher. Final sizing and reduction is determined by the closed side setting or the gap between the two crushing members at the lowest point.

The Symons cone crusher is adjusted by spinning the bowl up or down manually or through hydraulic rams. A series of powerful springs give the necessary tramp protection without damage to the crusher.

| Model | Cavity Type | Crushing Cone Dia.(mm) | Adjusting Range of Discharge Opening(mm) | Max feeding size (mm) | Capacity (t/h) | Motor (kw) | Overall size (mm) |

| CS75 | C | 900(3') | 13-38 | 150 | 59-163 | 75 | 2656×1636×2241 |

| CS75 | M | 900(3') | 9-22 | 85 | 45-91 | 75 | 2656×1636×2241 |

| CS75 | F | 900(3') | 3-13 | 35 | 27-90 | 75 | 2656×1636×2241 |

| CS110 | C | 1200(4') | 19-50 | 180 | 110-250 | 132 | 2821×1974×2651 |

| CS110 | M | 1200(4') | 13-38 | 130 | 80-180 | 132 | 2821×1974×2651 |

| CS110 | F | 1200(4') | 9-31 | 90 | 63-140 | 132 | 2821×1974×2651 |

| CS160 | C | 1295(4 1/4') | 19-51 | 205 | 172-349 | 160 | 2983×1866×3156 |

| CS160 | M | 1295(4 1/4') | 16-38 | 178 | 132-253 | 160 | 2983×1866×3156 |

| CS160 | F | 1295(4 1/4') | 13-31 | 115 | 109-181 | 160 | 2983×1866×3156 |

| CS220 | C | 1400(4 1/2') | 30-60 | 235 | 210-530 | 220 | 3360x2650x3050 |

| CS220 | M | 1400(4 1/2') | 22-45 | 180 | 180-475 | 220 | 3360x2650x3050 |

| CS220 | F | 1400(4 1/2') | 19-40 | 100 | 130-260 | 220 | 3360x2650x3050 |

| CS250 | C | 1650(5 1/2') | 25-64 | 228 | 299-635 | 250 | 3941×2954×3771 |

| CS250 | M | 1650(5 1/2') | 22-51 | 205 | 258-417 | 250 | 3941×2954×3771 |

| CS250 | F | 1650(5 1/2') | 16-38 | 178 | 181-327 | 250 | 3941×2954×3771 |

| CS315 | C | 2135(7') | 31-64 | 314 | 1125-1814 | 400 | 4613×3302×4638 |

| CS315 | M | 2135(7') | 25-51 | 284 | 862-1424 | 400 | 4613×3302×4638 |

| CS315 | F | 2135(7') | 19-38 | 236 | 544-1034 | 400 | 4613×3302×4638 |

*The output will vary according to different materials, feed particle size and other factors.

Save Time! Get A Detailed Quotation Quickly.