Preface: Jaw crusher is a crucial coarse and medium crushing equipment in mining, building materials, infrastructure and other industries. With its significant advantages such as simple structure, convenient manufacturing and reliable operation, jaw crusher has always occupied a key position in the crushing operation of various materials. With the rapid development of industrial technology and the increasing diversification of market demand, the technology of jaw crusher is also constantly innovating. In-depth analysis of its technical status and development trend has important practical significance for promoting the efficient development of related industries.

A. Technical status of jaw crusher

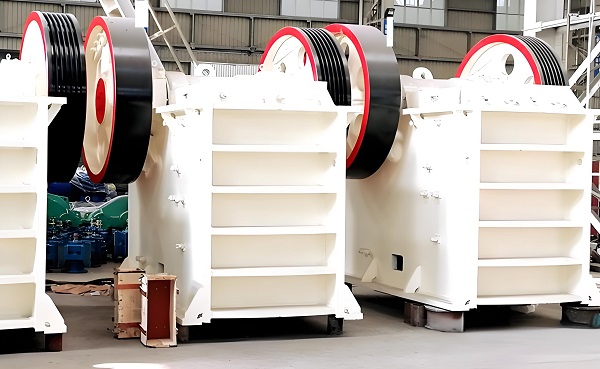

Jaw Crusher

1. Significant differentiation in manufacturing level

There are many jaw crusher manufacturers, but their technical levels are obviously uneven. A few manufacturers with advanced technical strength have basically reached the world's advanced level in terms of quality, performance stability and degree of automation, and can meet the stringent needs of the high-end market. It cannot be ignored that most manufacturers still have a large gap compared with the international advanced level. These gaps are mainly reflected in poor processing accuracy, resulting in unstable product quality; short service life of key components, increasing the maintenance cost of equipment; and overall performance is not stable enough, making it difficult to adapt to complex and changing working environments.

2. Differences in frame structure design

The frame accounts for a large proportion of the overall weight of the jaw crusher, of which the cast frame accounts for about 50% and the welded frame accounts for about 30%. Advanced manufacturing countries such as Europe and the United States mostly use welded frames, and even the movable jaw also uses a welded structure. This is because the welded frame has the outstanding advantages of high strength and light weight, which can effectively improve the overall performance and operating efficiency of the equipment, and represents the future development direction of the jaw crusher frame structure.

Some manufacturers have unreasonable design of the frame structure. They failed to fully arrange the reinforcement ribs scientifically and reasonably based on the stress conditions during the actual operation of the crusher, which not only affected the overall strength and stability of the equipment, but also shortened the service life of the equipment to a certain extent, reducing the market competitiveness of the equipment.

3. Development trend of equipment specifications and types

With the continuous expansion of open-pit mining, large electric shovels and large mining vehicles are widely used in mining, and the size of ore transported to the crushing workshop continues to increase. The grade of the original ore is gradually reduced. In order to maintain the production capacity of the ore dressing plant, the mining and crushing of the original ore must be increased. This series of changes has prompted the jaw crusher to develop in the direction of large-scale.

The largest jaw crusher manufactured abroad has reached a quite astonishing scale. With the continuous improvement of the material of large rolling bearings and the growing demand for underground coarse crushing equipment, the compound swing jaw crusher also shows a trend of large-scale development. There are still some urgent problems in the structure of the compound swing jaw crusher, which need further in-depth research and improvement.

B. Development trend of jaw crusher

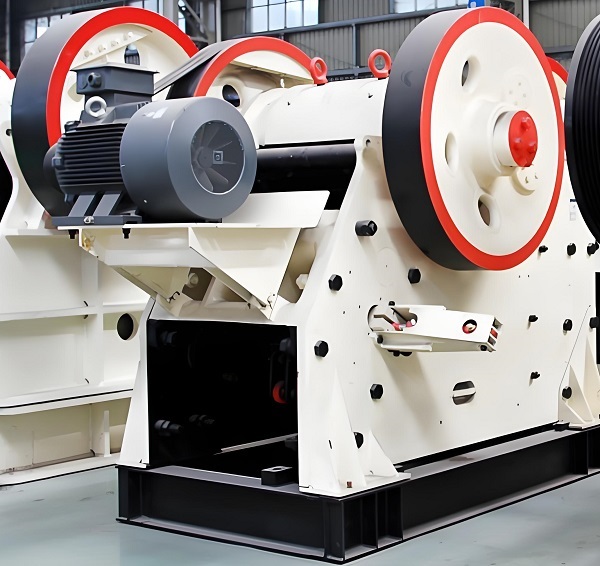

Jaw Crusher

1. Acceleration of intelligent and automated process

With the rapid development of artificial intelligence, sensor technology, and automated control technology, the intelligence and automation of jaw crushers have become an unstoppable and important development trend. The future jaw crusher will be equipped with an advanced intelligent control system that can monitor the operating status of the equipment in real time and accurately, including key parameters such as bearing temperature, vibration, and motor current. Through real-time analysis and processing of these data, the intelligent control system can automatically adjust the operating parameters of the equipment to achieve intelligent and refined operation.

Once the equipment fails, the intelligent diagnosis system can quickly and accurately locate the fault point and provide corresponding solutions in time. This not only greatly improves the maintenance efficiency and reliability of the equipment, but also effectively reduces downtime, reduces production costs, and provides strong guarantees for the efficient production of enterprises.

2. Large-scale development continues to deepen

In order to meet the growing demand for large-scale ore mining and processing, the large-scale trend of jaw crushers will be further strengthened. Large-scale equipment can not only significantly improve production efficiency and reduce unit production costs, but also reduce the number of equipment, facilitate centralized management and maintenance, and improve the production management level of enterprises.

In the future, with the continuous breakthroughs and innovations in material science and manufacturing processes, larger specifications and higher performance jaw crushers will be manufactured. Its key indicators such as feed particle size and production capacity will be further improved, providing more powerful equipment support for the large-scale development of industries such as mining.

Jaw Crusher

3. Energy saving and environmental protection have become the core appeal

Under the background of actively advocating green development around the world, energy saving and environmental protection have become an inevitable requirement for the development of jaw crushers. On the one hand, by optimizing the structural design and motion parameters of the crusher, the crushing efficiency can be effectively improved and the unit energy consumption can be reduced. For example, adopt a new type of crushing chamber shape to make the movement of materials in the crushing chamber more reasonable and reduce the ineffective loss of energy; improve the swing mode of the movable jaw to improve the crushing effect of the material, thereby reducing energy consumption.

On the other hand, actively develop and apply new energy-saving drive systems, such as adopting high-efficiency energy-saving motors, variable frequency speed regulation technology, etc., to flexibly adjust the operating power of the equipment according to actual production needs to achieve energy-saving operation. At the same time, attach great importance to reducing the emission of pollutants such as dust and noise during the operation of the equipment, and reduce the negative impact on the environment by adopting advanced sealing technology and dust removal devices, so as to achieve a win-win situation of economic and environmental benefits.

4. Multi-function and specialization trends are prominent

With the continuous refinement and specialization of industrial production, the functional requirements of jaw crushers are becoming increasingly diversified. In the future, jaw crushers will accelerate their development in the direction of multi-function and specialization, and special crushers with special functions will be developed for different material characteristics and production process requirements.

For ores with extremely high hardness, jaw crushers with stronger crushing force and wear resistance are developed to ensure efficient crushing; for production processes with special requirements for product particle size distribution, crushers that can accurately control product particle size are designed to meet the personalized needs of different users. In addition, it is possible to integrate multiple crushing functions into one, so as to achieve the production of products with multiple particle size requirements in one crushing, greatly improving production efficiency and product quality.

Jaw Crusher

5. Optimizing structure and innovating materials in parallel

Continuously optimizing the structural design of jaw crushers and further improving the reliability and stability of equipment are important directions for the development of the industry. For example, advanced technical means such as finite element analysis are used to conduct comprehensive and in-depth strength and stiffness analysis of key components of crushers, optimize structural shape and size, reduce stress concentration, and effectively improve the service life of components.

At the same time, actively carry out the research and development and application of new materials to improve the wear resistance and impact resistance of crushers. New alloy materials are used to manufacture vulnerable parts such as jaw plates and thrust plates, which significantly improves their wear resistance and impact resistance, reduces replacement frequency, and reduces maintenance costs. High-strength and lightweight materials are used on structural parts such as the frame to reduce the weight of the equipment, reduce manufacturing and transportation costs, and enhance the market competitiveness of the equipment while ensuring the strength of the equipment.

PS: As an important crushing equipment, the jaw crusher has achieved certain development results under the current technological status, but it also faces many challenges. With the continuous advancement of science and technology and the continuous promotion of market demand, its future development trend is very clear. Intelligence, large-scale, energy-saving and environmental protection, multi-function and specialization, as well as structural optimization and material innovation will become the key directions of development. This will not only help to improve the performance and market competitiveness of the jaw crusher, but also provide strong support for the sustainable development of related industries such as mining and building materials. All manufacturers should keep up with the trend of technological development, increase R&D investment, and continue to innovate to meet the market demand for high-performance jaw crushers and promote the overall progress of the industry.

Save Time! Get A Detailed Quotation Quickly.