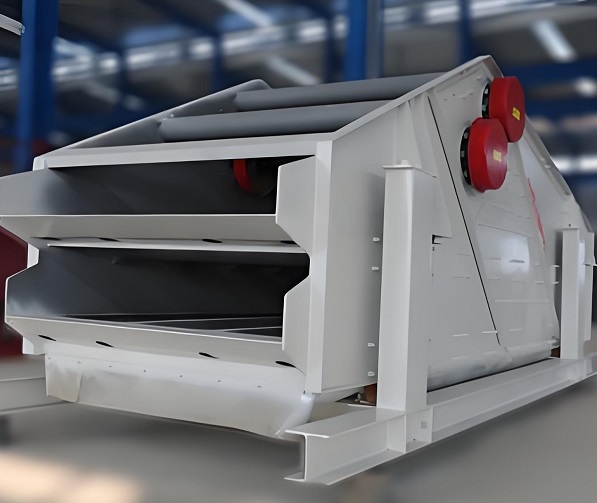

Dewatering screen is a kind of linear dehydrated medium vibrating screen. It is used to remove excess moisture in fine aggregates and sand and you can achieve moisture content as low as 8%.

1. The motor is easy to replace, and the rubber spring on the base has a shock-absorbing effect and can be dehydrated cleanly.

2. Can be adjusted according to yield and moisture content. The side plates of the machine body are reinforced with plates, and the discharging materials are supported by triangular steel plates.

3. The vibration motor is fixed with high-strength bolts, and the screen plate has reinforced ribs.

4. For products with low mud content, the dewatering screen can also be used directly without sand washing, saving user costs and achieving the same effect.

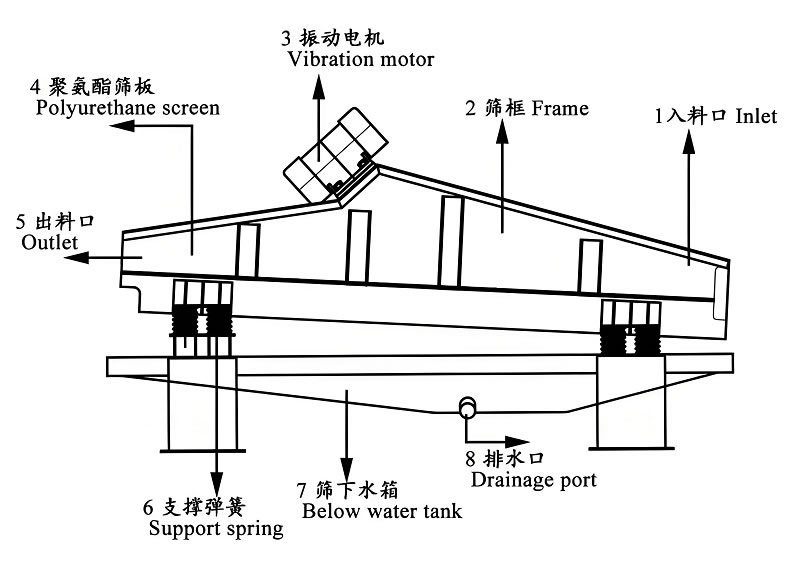

Vibrator is mounted on the side plate, which provides a good stress condition.

The screen plate adopts modular polyurethane screen plate, which requires no bolts and reduces clogging. The screen holes can be customized as needed.

Specially designed frequency, amplitude and low power consumption enable continuous operation 24 hours a day.

Dewatering Screen can be added any sand washer to drastically cut moisture content, leaving you with a drier product that you can sell sooner.

Dewatering screen adopts double vibration motor as power supply. The two motors that rotate synchronously and reversely and centrifugal force are produced by two groups of eccentric block. This makes the screen body periodical to-and-fro moving along the direction of straight line, which is for the purpose of dehydration. The slurry passes through the screen and becomes under the screen, while the fine materials are blocked by the screen to form a filter layer and are affected by the vibration force. Counter-rotating motors create a motion that conveys solids to the discharge end of the screen as water drains through the screen media.

| Model | Max Feeding Size | Motor Power (kw) | Capacity (t/h) | Dewatering Screen | Overall size(mm) | |

| Spec(mm) | Area (m2) | |||||

| ZSD1230 | ≤10 | 1.9 | 30-80 | 1200×3000 | 3.6 | 3085x1590x1439 |

| ZSD1236 | ≤10 | 2.2 | 30-80 | 1200×3600 | 4.32 | 3677x1590x1600 |

| ZSD1530 | ≤10 | 2.3 | 80-120 | 1500×3000 | 4.5 | 3075×2491×1601 |

| ZSD1536 | ≤10 | 3 | 80-120 | 1500×3600 | 5.4 | 3200×2491×1802 |

| ZSD1836 | ≤10 | 7.5 | 100-140 | 1800×3600 | 6.48 | 3758×3075×1988 |

| ZSD1842 | ≤10 | 7.5 | 100-140 | 1800×4200 | 7.56 | 4368×3075×2000 |

| ZSD1848 | ≤10 | 7.5 | 100-140 | 1800×4800 | 8.64 | 4791×3065×1959 |

| ZSD2442 | ≤10 | 11 | 140-180 | 2400×4200 | 10.1 | 4403×3737×1931 |

| ZSD2448 | ≤10 | 11 | 140-180 | 2400×4800 | 11.52 | 5008×3737×1977 |

| ZSD3048 | ≤10 | 15 | 200-250 | 3000×4800 | 14.4 | 4959×4518×2218 |

*The output will vary according to different materials, feed particle size and other factors.

Save Time! Get A Detailed Quotation Quickly.