Introduction: Eddy current separator is a highly efficient metal separation equipment, which uses the principle that conductors generate eddy currents in a high-frequency alternating magnetic field to effectively separate metals from non-metals. The device generates a high-frequency changing magnetic field through the high-speed rotation of the internal magnetic core roller. When a metal object enters the magnetic field, eddy currents are generated inside it, which in turn generate a magnetic field that interacts with the external magnetic field, thereby achieving the separation of the metal object.

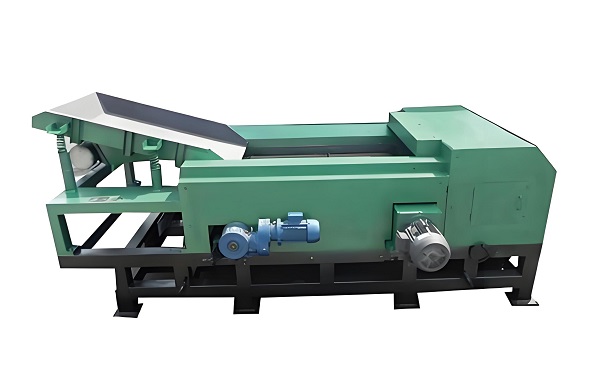

Eddy Current Separator

Eddy current separator has the characteristics of high sorting efficiency, easy operation and environmental friendliness. It is suitable for sorting various metal materials, especially separating valuable non-ferrous metals such as aluminum and copper from waste. In addition, the equipment has a simple structure, low maintenance cost, and can be flexibly adjusted according to different materials. It is widely used in scrap metal recycling, garbage sorting and other fields, making important contributions to resource recycling and environmental protection.

As an advanced sorting equipment, Zhongcheng Machinery's eddy current separator has significant characteristics and advantages. The following is a detailed summary of its characteristics and advantages:

A. Characteristics of Zhongcheng Machinery Eddy Current Separator

Eddy Current Separator

1.Structural composition:

The eddy current separator consists of an endless conveyor belt, an internal magnetic core roller, an external magnetic roller, etc. The core component is a high-frequency AC magnetic field generator that can generate a high-frequency alternating magnetic field.

2. Working principle:

The magnetic poles built into the magnetic core roller inside the eddy current rotate at high speed, causing the magnetic field to change at high frequency. The high-frequency changes in the magnetic field cause extremely strong eddy currents to be generated in the non-ferrous metal fragments. The magnetic field generated by the eddy currents interacts with the external magnetic field, causing the non-ferrous metal fragments to be separated from the original material flow. When a metal object enters the magnetic field, eddy currents are generated due to electromagnetic induction, which in turn generates heat and mechanical vibrations, thereby achieving the sorting effect.

3. Model selection:

Two types of machines are available: concentric and eccentric, for sorting different materials.

4. Adjustment function:

The conveyor belt speed and magnetic roller speed can be adjusted by variable frequency. The dividing plate can be adjusted forward, backward and at an angle according to different materials.

B. Advantages of Zhongcheng Machinery Eddy Current Separator

Eddy Current Separator

1. Efficient sorting:

The eddy current separator has extremely high sorting efficiency and can quickly and accurately identify and separate various metals. Whether it is large pieces of metal or tiny particles, they can be effectively processed. It can continuously and effectively separate non-ferrous metals copper and aluminum at one time. The working efficiency of the equipment is more than 10 times that of manual labor and can run continuously for 24 hours.

2. Wide range of applications:

The equipment is suitable for sorting various metal materials, including common metals such as iron, copper, aluminum, as well as some rare metals and mixed materials. It is especially suitable for separating valuable non-ferrous metals such as aluminum, copper, zinc, etc. from waste.

3. Easy to operate:

The eddy current separator is easy to operate. You only need to put the material to be processed into the equipment and start the equipment to complete the sorting work without manual intervention. The equipment control system is simple and convenient, with one-button operation, requiring little manpower, and basically no maintenance after debugging.

4. Environmentally friendly:

The equipment does not produce any harmful substances during the treatment process and is environmentally friendly. The noise level is low during operation, which is beneficial to improving production efficiency.

5. Low maintenance cost:

The equipment has a simple structure and reasonable design. All components have been optimized through computer simulation and have a low failure rate. The production cost and power consumption of the equipment in normal operation are low. The equipment has fewer parts that require maintenance in the later stages, and the cost is low if maintained properly.

6. High sorting accuracy:

The eddy current separator can effectively separate non-ferrous metals with higher purity and increase the value of resource recovery. It can sort small and medium-sized materials that cannot be sorted manually, and the sorting rate is high. Usually, under ideal material conditions, the sorting rate of the sorting machine can reach 98%.

Eddy Current Separator

7. Other advantages:

a. It adopts high-strength performance equipment to generate high-strength magnetic field, and cooperates with high-performance inverter adjustment to sort out non-ferrous metal materials above 3mm.

b. Delay the attenuation of magnetic force of the magnet and extend the service life of the whole machine.

c. The high-speed magnetic roller core is dynamically balanced according to the level of the grinder spindle, so that the noise during equipment operation is controlled within 70dba.

d. The integral drive reducer has stable drive and variable frequency speed regulation, which can meet the use of materials with different particle size ranges.

e.Using unique structural modules, the transport belt can be replaced without disassembling the drive and magnetic rollers, making replacement quick and convenient.

f. According to the different characteristics of the materials, it is combined with a vibrating feeder, an iron remover, etc. to form a "combined eddy current separator", which can be flexibly configured to reduce floor space and investment.

PS: Zhongcheng Machinery's eddy current separator plays an important role in the field of metal separation due to its technical advantages such as high efficiency, environmental protection and easy operation. With the continuous advancement of technology and the continuous expansion of application fields, the application prospects of eddy current separators will be broader.

Save Time! Get A Detailed Quotation Quickly.