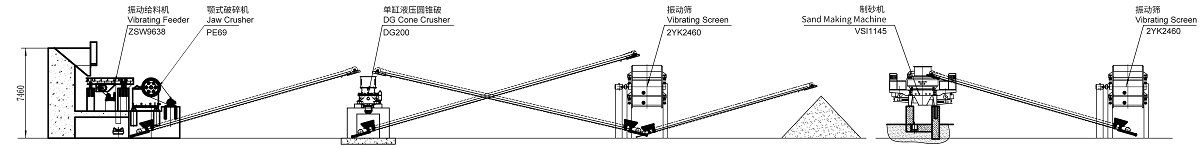

1. Granite crusher plant includes Vibrating feeder, primary jaw crusher, cone crusher, vibrating screen, belt conveyor, electrical cabinet.

2. Firstly granite is sent to the jaw crusher through the feeder for rough crushing. Thencrushed stones go to cone crusher through belt conveyor for secondary crushing. Finally they are sent to circular vibrating screen for classify. The output is 0-6mm, 6-12mm, 12-25mm.

3. All selected equipment of this production line is mature equipment after long-term market inspection. And it has very complete design, production, and processing technology. The processed finished product has uniform particle size, excellent particle size, and stable output.

1. Feeding equipment, like vibration feeder or plate type feeder: These machines feed the jaw crusher with the rocks and stones to be crushed.

2. Crushing equipment: These are the machines where the rocks and stones are crushed. Generally jaw crushers and Gyratory crushers are used for primary crushing, while impact crusher, Symons cone crusher, sand crusher are used for secondary crushing and tertiary crushing.

3. Vibrating Screen: These machines are used to separate the different sizes of the material obtained by the crushers.

4. Belt Conveyor: They are used for transportation of the material from one machine to another during different phases of process.

5. Central electric control system: Control and monitor the operation of the entire system.

Save Time! Get A Detailed Quotation Quickly.