Large-scale stone crushing plant 800tph crusher plant is typically consists of primary, secondary, and tertiary crushers, screens, conveyors, and other equipment necessary for the crushing process. Jaw crusher PE1200*1500 with capacity 400-1000 tph is used as primary crushing equipment. Secondary crushing equipment adopts two HPC cone crusher or impact crusher.It could produce sand & gravels with various granularities of limestone, granite, dolomite, quartz, ballast, basalt, marble, iron ore, cooper ore etc.

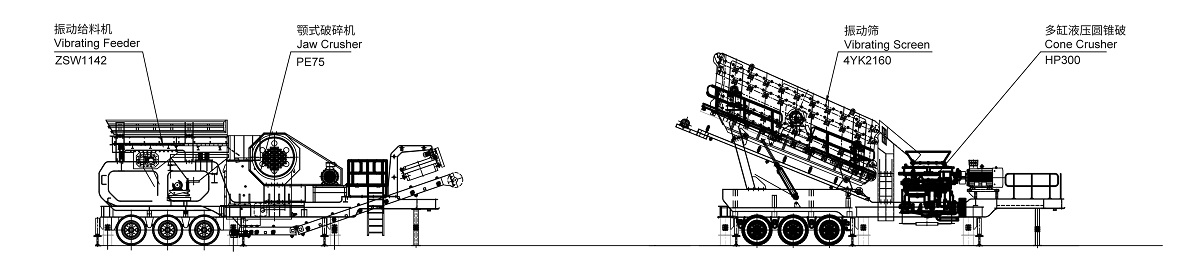

Equipment configuration

| Hopper LC6000X8000, Vibrating feeder ZSW1560,Vibrating feeder GZG125-4,PE1200X1500 Jaw Crusher, Impact Crusher PFW1515,Impact Crusher PFW1214, 2YK3080 Vibrating Screen,, 3YK3080 Vibrating Screen, Spiral sand washer XL1120,and belt conveyor |

Raw materials

| This stone plant can crush more than 120 kinds of ore materials such as Feldspar, limestone, granite, basalt, Riverstone, and rocks. |

Feed Size

| 1020mm |

Capacity

| 800t/h |

Finished product

| 40 mm and down |

Design requirements

| 1.The required production capacity 2.The type, hardness, and abrasiveness grade of the crushed material 3.the maximum size of the feed 4.The size of the desired final fraction |

1. It could manufacture of aggregates (coarse aggregates, crusher run, rock sand, fine aggregates) from limestone, granite, andesite, etc. Coarse aggregates are usually used in ready mix concrete and asphaltic concrete. Crusher run is used for the bases and sub-bases for road making. Fine aggregates are used for the production of concrete and plastering.

2. The final size is 0-6mm(0-1/4' ), 6-12mm(1/4’-1/2’), 12-25mm( 1/2’-1’)(or other sizes according to your need) as aggregate for construction.

3. High degree of automatic operation. The whole crushing plant requires sevral workers for machine starting and stopping, routine maintenance.

4. High production efficiency, regular end product granularity, good grain shape, and low powder content.

5. Adopting high advanced control system to ensure security and reliable operation of the entire stone crushing plant.

Save Time! Get A Detailed Quotation Quickly.