Preface: In industries such as ore mining and building materials production, cone crushers are key equipment for achieving efficient material crushing. Their performance is directly related to the production efficiency, cost control and long-term development of enterprises. However, there are many brands and models of cone crushers on the market, and the quality is also uneven, which undoubtedly adds a lot of troubles to buyers. In order to help buyers accurately and efficiently purchase ideal equipment, this article will deeply analyze the purchase skills of cone crushers.

A. Accurately locate your own needs

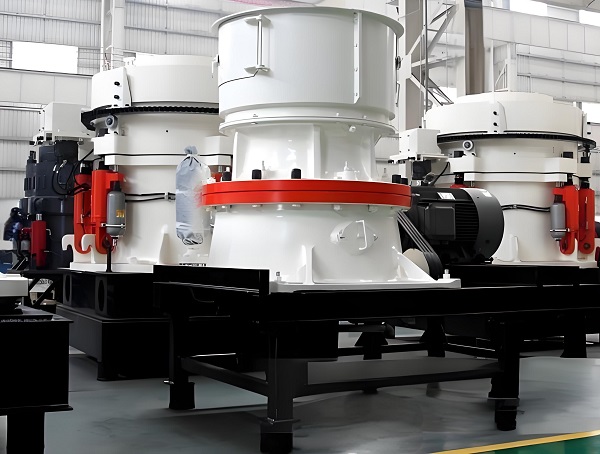

Cone Crusher

1. Clear production requirements

Before purchasing a cone crusher, enterprises need to accurately determine the output of the required equipment based on their own production plans and actual production scale. Through in-depth analysis of past production data and reasonable expectations of the future market, the crushing output that the equipment needs to achieve per hour or day is estimated. For example, if an enterprise plans to expand its production scale and expects to process 5,000 tons of ore per day in the future, then when selecting the model, the theoretical output of the selected cone crusher should be able to meet or even moderately exceed this demand, so as to calmly deal with possible production peaks or efficiency fluctuations.

2. Consider material characteristics

Different materials have significant differences in hardness, humidity, viscosity, etc. These characteristics will directly affect the selection and actual performance of the cone crusher. For materials with higher hardness, such as iron ore and quartz stone, a cone crusher with strong crushing force and excellent wear resistance should be selected; for materials with higher humidity, it is necessary to focus on the anti-blocking performance of the equipment to prevent the crushing chamber from being blocked due to moisture in the material, thereby affecting production efficiency. In addition, materials with higher viscosity tend to adhere to the crushing wall and the mortar wall, reducing the crushing effect, so the equipment structure that is easy to clean and maintain should be preferred.

3. Clarify the finished product particle size requirements

Clarifying the required finished product particle size is one of the key bases for purchasing a cone crusher. Different production uses have different requirements for finished product particle size. For example, construction sand usually requires a particle size between 0-5mm, while the metallurgical industry may have more stringent standards for the particle size distribution of ore particles. When purchasing equipment, you need to fully understand the range of finished product particle sizes that the selected cone crusher can produce, and whether it can flexibly meet different particle size requirements by adjusting equipment parameters (such as the size of the discharge port).

B. Comprehensively examine the quality of the equipment

Cone Crusher

1. Evaluate brand and reputation

Choosing a cone crusher from a well-known brand often provides more reliable quality assurance. Well-known brands usually have been deeply involved in the industry for many years, have accumulated rich production experience, and have advanced production processes and strict quality control systems. Purchasers can widely understand the reputation and user reviews of cone crushers of different brands through online searches, participation in industry forums, and consulting peer companies. For example, some internationally renowned brands have a large user base worldwide, and their products are highly praised for their high stability and durability; at the same time, some excellent domestic brands are also continuously improving product quality, and occupy an important share in the market with their high cost-effectiveness.

2. Examine materials and processes

The materials and manufacturing processes of the main components of the cone crusher need to be carefully examined. Crusher frame, eccentric sleeve, crushing cone and other key parts should be made of high-strength, wear-resistant materials, such as high-quality alloy steel, to ensure the stability and reliability of the equipment under long-term high-load operation. In terms of manufacturing technology, advanced processing technology can ensure the accuracy and assembly quality of parts, effectively reduce the vibration and noise during equipment operation, and comprehensively improve the overall performance of the equipment. For example, the use of CNC processing technology can control the dimensional accuracy of parts within a very small error range, thereby significantly improving the operating stability of the equipment.

3. Conduct field visits

If conditions permit, buyers should try to go to the manufacturer or equipment use site for field visits. At the manufacturer, you can directly observe the production process of the equipment and gain an in-depth understanding of the manufacturer's production strength and quality control measures; at the equipment use site, you can witness the actual operation of the equipment, including the stability of the equipment, crushing effect, noise level, etc., and you can also communicate with the on-site operators to obtain their real experience and evaluation of the equipment.

C. Reasonable comparison of price and cost

Cone Crusher

1. Analyze the price of equipment

When purchasing a cone crusher, price is certainly an important consideration, but the purchase decision cannot be made solely based on the price. The prices of cone crushers of different brands, models and specifications vary greatly. Purchasers should conduct a comprehensive comparative analysis of the product prices of multiple brands and manufacturers on the premise of meeting their own needs and quality requirements. You can collect market price information extensively by consulting multiple suppliers for quotes, participating in equipment exhibitions, etc., and select products with high cost performance.

2. Calculate operating costs

In addition to the purchase price of the equipment, the operating costs of the equipment must also be fully considered, including energy consumption, replacement costs of wearing parts, and maintenance costs. In terms of energy consumption, choosing an energy-saving cone crusher can reduce long-term electricity consumption costs; the replacement cost of wearing parts is closely related to the wear and tear of the equipment and the price of wearing parts. Purchasers need to understand the service life and market price of the wearing parts of the equipment and choose equipment with lower wearing parts costs; the maintenance cost includes regular maintenance costs, maintenance labor costs, etc. Equipment with simple structure and convenient maintenance can effectively reduce maintenance costs.

3. Conduct a total cost analysis

Comprehensively consider the equipment price and operating costs, and conduct a comprehensive total cost analysis. For some equipment with high price but low operating cost and long service life, the total cost may be lower in the long run; while some equipment with low price but high energy consumption and frequent replacement of wearing parts may greatly increase the cost in the later operation. Therefore, the purchaser needs to select the cone crusher with the lowest total cost through detailed cost accounting.

D. Pay close attention to after-sales service

Cone Crusher

1. Pay attention to after-sales response time

High-quality after-sales service is an important support for the normal operation of equipment. When purchasing equipment, the purchaser should understand the supplier's after-sales response time to ensure that timely maintenance support can be obtained when the equipment fails. Generally speaking, the supplier should respond within 24 hours after receiving customer fault feedback and arrange technicians to go to the site for repair as soon as possible. For some emergency faults, such as damage to key components that affect production continuity, the supplier should be able to quickly provide solutions, such as providing spare parts.

2. Consider the strength of technical support

The supplier should be equipped with a professional technical team that can provide customers with comprehensive technical support. This includes equipment installation and commissioning, operation training, daily maintenance guidance, etc. During the equipment installation and commissioning stage, the technicians should ensure that the equipment is installed correctly and conduct comprehensive commissioning of the equipment to achieve the best operating state; in terms of operation training, detailed operation training should be provided to operators to familiarize them with the equipment's operating procedures, precautions and safety specifications; during the daily operation of the equipment, the supplier should answer technical questions for customers at any time and provide professional maintenance suggestions.

3. Ensure the timeliness of spare parts supply

Ensuring that the supplier can provide the original spare parts of the equipment in a timely manner is crucial for the normal repair and maintenance of the equipment. The quality and performance of the original spare parts are more compatible with the equipment, which can effectively guarantee the repair effect and service life of the equipment. The purchaser should understand the supplier's spare parts inventory and supply cycle to avoid long-term equipment downtime due to spare parts shortage.

E. Pay attention to other purchase points

Cone Crusher

1. Carefully review the contract terms

Before signing the purchase contract, the purchaser must carefully review the contract terms to ensure that the contract content is clear and complete, covering the equipment model, specifications, price, delivery time, quality standards, after-sales service terms, breach of contract liability, etc. For some important terms, such as the equipment quality guarantee period, the specific content and cost of after-sales maintenance services, etc., detailed agreements should be made to avoid disputes later.

2. Reasonably determine the payment method

Reasonably choose the payment method, which should not only ensure the safety of your own funds, but also take into account the interests of suppliers. Common payment methods include prepayment, cash on delivery, installment payment, etc. Purchasers can negotiate and determine the appropriate payment method based on the equipment price, supplier reputation and the cooperative relationship between the two parties. For example, for equipment with higher prices, installment payment can be adopted to reduce the financial pressure of the enterprise; for suppliers with good reputation, the prepayment ratio can be appropriately increased to obtain more favorable prices and better services.

3. Clarify the transportation and installation responsibilities

Clarify the transportation method and installation responsibilities of the equipment. To ensure that the equipment is not damaged during transportation, the supplier should provide appropriate packaging and transportation solutions; for installation, it is necessary to determine whether the supplier is responsible for installation and commissioning, or the enterprise arranges the installation by itself. If the supplier is responsible for installation, the installation time, quality standards and acceptance methods should be clearly stated in the contract.

PS: Purchasing a cone crusher requires comprehensive consideration of many factors. Through a series of purchasing skills such as accurately positioning your own needs, comprehensively examining the quality of equipment, reasonably comparing price costs, and paying close attention to after-sales service, a scientific and reasonable purchase decision can be made. Only in this way can we purchase a cone crusher with excellent performance, high cost performance and the ability to meet the production needs of the enterprise, providing strong equipment support for the development of the enterprise.

Save Time! Get A Detailed Quotation Quickly.