Preface: In the complex and critical industrial field of ore crushing, the spring cone crusher has become a widely used and highly anticipated crushing equipment with its unique design and stable and reliable performance. From traditional mining to related industries such as building materials production and metallurgical processing, the spring cone crusher plays a pivotal role. Next, this article will conduct a comprehensive and in-depth analysis of the spring cone crusher.

A. Structural composition of the spring cone crusher

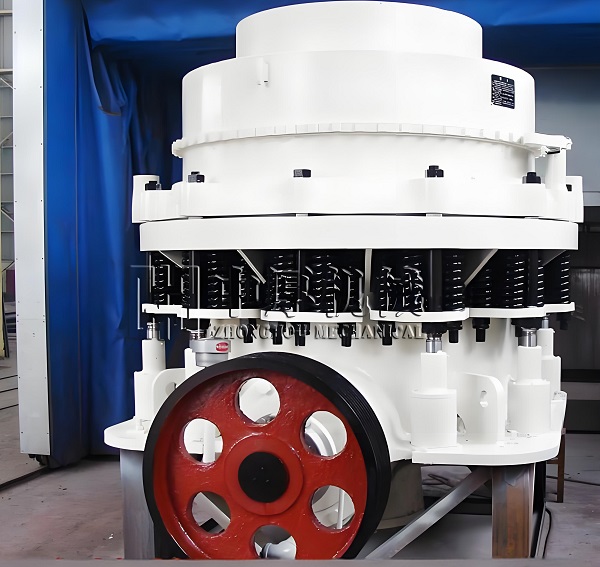

Spring Cone Crusher

The spring cone crusher is mainly composed of a frame, a transmission device, an eccentric sleeve, a crushing cone, a mortar wall, a crushing wall, an adjustment device, and a spring safety device.

Frame: As the basic support structure of the entire equipment, the frame is carefully made of high-strength cast steel material, with sufficient strength and stability, and can steadily withstand the huge crushing force and strong vibration generated by the equipment during operation, laying a solid foundation for the stable operation of the equipment.

Transmission device: It is usually composed of components such as a motor, a pulley, and a transmission shaft. The motor efficiently transmits power to the drive shaft with the help of the pulley, which in turn drives the eccentric sleeve to rotate continuously, providing strong power support for the crushing operation of the crusher.

Eccentric sleeve: This is one of the core key components of the spring cone crusher. Driven by the drive shaft, the eccentric sleeve performs eccentric rotation, which causes the crushing cone fixed on it to produce a unique swinging motion, and this swinging motion is the key action to achieve material crushing. The processing accuracy and material quality of the eccentric sleeve have a direct and significant impact on the operating stability and crushing efficiency of the equipment.

Crushing cone and mortar wall, crushing wall: The crushing cone is a key component that directly acts on the material for crushing, and the crushing wall is tightly installed on its surface; the mortar wall is firmly fixed on the frame and is set opposite to the crushing wall. When the material enters the crushing chamber from the feed port of the crusher, during the swinging motion of the crushing cone, the material will be continuously subjected to the composite forces of extrusion, impact and bending of the crushing wall and mortar wall, and then gradually crushed.

Adjustment device: It is mainly used to flexibly adjust the size of the crusher's discharge opening to meet different actual production needs and material particle size requirements. At present, the common adjustment methods are mainly hydraulic adjustment and manual adjustment. Among them, the hydraulic adjustment method is more convenient and efficient to operate, and can realize remote intelligent control and automatic precision adjustment, which greatly improves the convenience of operation and production flexibility.

Spring safety device: This is a significant feature of the spring cone crusher that distinguishes it from other types of cone crushers. During the normal operation of the crusher, once an unbreakable foreign body (such as iron blocks, etc.) accidentally enters the crushing chamber, the spring will be compressed by strong pressure, and then the crushing cone will be lifted upward, and the discharge opening will increase immediately, ensuring that the foreign body can be discharged smoothly, effectively avoiding damage to the key components of the equipment. After the foreign body is successfully discharged, the spring will quickly return to its original state, allowing the crusher to smoothly return to normal working state.

B. Working principle of spring cone crusher

Spring Cone Crusher

The working principle of the spring cone crusher is based on an efficient extrusion crushing method. After the equipment is started, the motor drives the eccentric sleeve to rotate at high speed through the transmission device. The eccentric motion characteristics of the eccentric sleeve make the crushing cone fixed on it produce regular swinging motion. In this process, the distance between the crushing wall and the mortar wall changes dynamically, sometimes approaching each other and sometimes moving away from each other. When the material enters the crushing chamber from the feed port, it will first be subjected to the initial squeezing effect of the crushing cone and the mortar wall. With the continuous swinging motion of the crushing cone, the squeezing, impact and bending forces on the material in the crushing chamber become stronger. Under the synergistic effect of these forces, the material is gradually crushed into smaller particles. After repeated crushing, the material that meets the particle size requirements will be discharged smoothly from the discharge port, thus completing the entire efficient crushing process.

C. Performance characteristics of spring cone crusher

Spring Cone Crusher

1. Large crushing ratio

The spring cone crusher has the excellent ability to achieve a large crushing ratio. Generally, the crushing ratio can reach 5-8, and even higher under some special working conditions. This means that it can quickly and efficiently crush larger-sized materials into smaller-sized products, which can fully meet the extremely strict requirements of different production processes for material particle size. For example, when processing medium-hard limestone, it can quickly crush larger stones into fine particles that meet the standards for building sand, effectively ensuring the particle size requirements for the production of building materials.

2. High production efficiency

Thanks to its unique and exquisite structural design and scientific and efficient working principle, the spring cone crusher can process a large amount of materials per unit time, showing extremely high production efficiency. In large-scale mining operations, a medium-sized spring cone crusher can process hundreds of tons per hour, which can fully meet the high-intensity requirements of large-scale production and provide solid equipment support for the efficient operation of mining enterprises.

3. Uniform product particle size

During the crushing process, the material can be uniformly squeezed and finely ground in the crushing chamber, which makes the particle size of the crushed product uniform and the particle size distribution range is extremely narrow. This outstanding feature makes the products produced by the spring cone crusher have better performance in subsequent processing and use. Taking the construction industry as an example, using sand and gravel with uniform particle size as aggregate can significantly improve the quality and stability of concrete, thereby improving the overall quality and safety of the building.

D. Common faults and maintenance of spring cone crusher

Spring Cone Crusher

1. Common faults

Excessive vibration of equipment: This fault may be caused by a variety of reasons such as the crusher's foundation is not strong enough, the eccentric sleeve is seriously worn, or foreign matter is mixed in the crushing chamber. Excessive vibration of the equipment will seriously affect the normal and stable operation of the equipment, and may even cause damage to equipment components, thereby affecting production progress and product quality.

Uneven discharge particle size: The problem of uneven discharge particle size may be caused by uneven wear of the crushing wall and the mortar wall, uneven feeding, or improper adjustment of the discharge port. This problem will directly affect the quality of the product, have an adverse effect on subsequent processing technology, and reduce the market competitiveness of the product.

Spring failure: Long-term continuous use or excessive impact force may cause the spring to lose elasticity or break, which will seriously affect the normal operation of the spring safety device, making the equipment unable to be effectively protected when encountering foreign matter, increasing the risk of equipment damage.

2. Maintenance measures

Regular inspection of equipment foundation: Regularly conduct a comprehensive and detailed inspection of the crusher foundation to ensure that the foundation is firm and reliable, and there is no loosening or sinking. Regularly tighten and maintain the foundation to effectively prevent excessive vibration of the equipment due to foundation problems, and provide a solid foundation for the stable operation of the equipment.

Check and replace wearing parts: Regularly check the wear of wearing parts such as the crushing wall, rolling mortar wall, eccentric sleeve, etc. Once severely worn parts are found, they should be replaced in time. At the same time, when selecting wearing parts, be sure to use reliable products to ensure that the performance and service life of the equipment are not affected.

Ensure uniform feeding: Reasonably adjust the feeding equipment to ensure that the material can enter the crushing chamber evenly. Avoid problems such as uneven discharge particle size and excessive equipment vibration due to uneven feeding, so as to ensure the stable operation of the equipment and the consistency of product quality.

Check and maintain the spring: Regularly check the elasticity and integrity of the spring. If the spring is found to be invalid or damaged, it should be replaced in time. At the same time, it is necessary to pay attention to proper lubrication and protection of the spring to effectively extend the service life of the spring and ensure that the spring safety device is always in good working condition.

E. Application field of spring cone crusher

Spring Cone Crusher

Spring cone crusher is widely used in many industries. In the field of mining, it is widely used in the crushing of various metal ores and non-metallic ores, such as iron ore, copper ore, limestone, quartz stone, etc.; in the building materials industry, it is used to produce important aggregates such as sand and gravel for construction, providing high-quality basic materials for construction projects; in the metallurgical industry, as a key and important equipment for ore pretreatment, it accurately provides raw materials of appropriate particle size for subsequent smelting processes to ensure the smooth progress of the smelting process; in road construction, it is used to crush various stones, provide high-quality basic materials for road paving, and help create high-quality road projects.

PS: Spring cone crusher occupies an extremely important position in the ore crushing industry with its unique structural design, efficient working principle, excellent performance characteristics and wide application fields. A deep understanding of its structure, working principle, performance characteristics and maintenance points is of vital importance for the correct selection, reasonable use and careful maintenance of the equipment, thereby improving production efficiency and product quality. With the continuous advancement and innovative development of science and technology, spring cone crusher is also continuously optimized and upgraded. In the future, it will surely play a more important role in more fields and contribute more to industrial development.

Save Time! Get A Detailed Quotation Quickly.