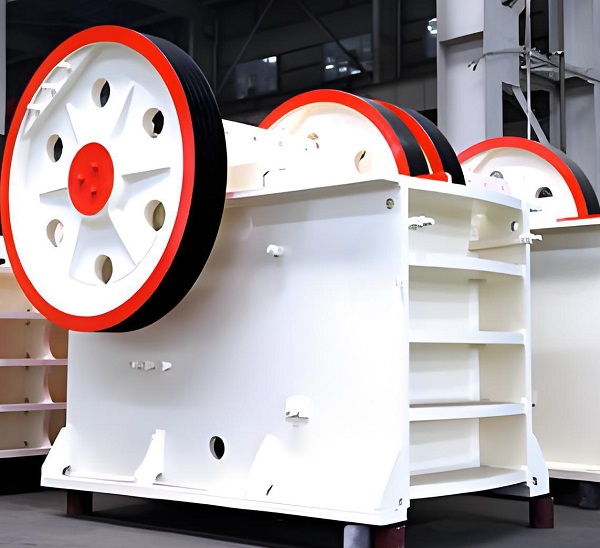

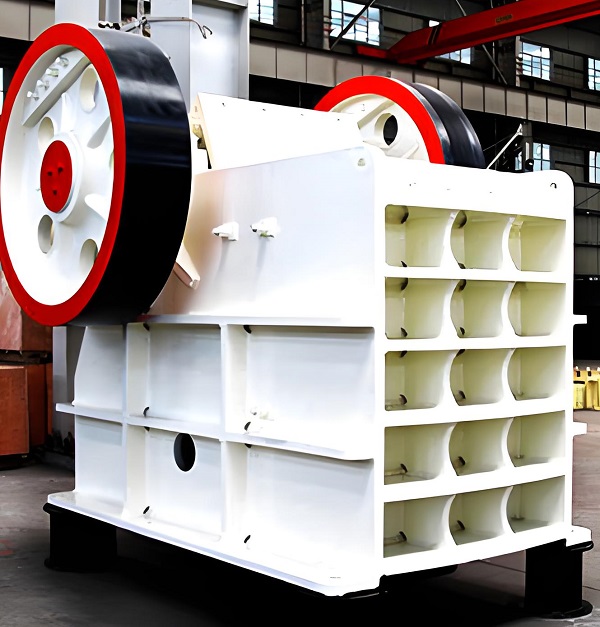

Preface: Jaw crusher plays an important role in mining, building materials, highway and railway construction and other fields. It mainly performs crushing operations such as squeezing, splitting and bending materials by simulating the movement of the two jaws of animals. The equipment has a simple structure, reliable operation, large crushing ratio, and can handle materials of various hardness. During the crushing process, the material is gradually crushed to the required particle size, thereby achieving efficient and energy-saving crushing operations. Jaw crusher also has the advantages of easy maintenance and low operating cost, and is an indispensable key equipment in many industrial fields. With its efficient and reliable crushing performance, jaw crusher provides strong support for the crushing and processing of various materials.

Jaw Crusher

The reason why jaw crusher cannot fail is mainly due to its importance to the production process and the chain reaction caused by its failure. Jaw crusher is a key equipment in many industrial fields. Once a failure occurs, it will directly lead to the shutdown of the production line and affect production efficiency. In addition, the failure may also cause material accumulation, equipment damage, and even cause safety accidents. Therefore, ensuring the stable operation of the jaw crusher is of great significance to maintaining the smooth production process, ensuring personnel safety, and reducing operating costs. Jaw crusher fault repair is crucial to the production and operation of enterprises. It is an important means to ensure smooth production and reduce operating costs.

1.Analysis and solution of the problem of declining production

a. Causes of failure

Material property changes: Once the physical properties of the material, such as hardness, humidity, and particle size, change significantly and exceed the design tolerance of the equipment, it is very likely to lead to a decrease in production. For example, when the humidity of the material increases significantly, its fluidity will decrease significantly, and it is easy to stick together in the crushing chamber, hindering the normal flow and crushing of the material, thereby affecting production efficiency. The originally smooth material conveying process will become slow due to the adhesion of the material, and the crusher will not be able to work continuously and efficiently, and the output will naturally be affected.

Severe wear of the jaw plate: As a key component that directly contacts the material and implements the crushing operation, the jaw plate will inevitably wear out during long-term high-intensity work. When the jaw plate wears to a certain extent, its crushing capacity will drop sharply, and the material cannot be effectively crushed, resulting in a decrease in production. The surface of the worn jaw plate is no longer flat, and the material is unevenly stressed during crushing, making it difficult to be crushed into an ideal particle size, and the crushing efficiency will also be greatly reduced. In addition, uneven wear of the jaw plate will also destroy the operating balance of the equipment, causing the equipment to vibrate more, further affecting production stability. Excessive vibration will not only cause additional loss to the parts of the equipment, but may also cause equipment failure, affecting normal production.

Discharge port blockage: If the discharge port is blocked by crushed materials or other foreign matter, the material cannot be discharged smoothly, and material accumulation will gradually form inside the crusher, resulting in a reduction in the crushing chamber space and a significant reduction in production efficiency. The reasons for the blockage of the discharge port are relatively complex. It may be that the size of the discharge port is too small to meet the discharge requirements of the material; the material particle size is uneven, and there are too large particles, which are easy to get stuck at the discharge port; the equipment is unstable, resulting in abnormal movement trajectory of the material in the crushing chamber, increasing the risk of blockage. Once the discharge port is blocked, the material continues to accumulate in the crushing chamber, the workload of the crusher will gradually increase, and may even cause the equipment to shut down.

Frequent failures of transmission components: loose belts will lead to reduced power transmission efficiency and unstable equipment speed; pulley wear will affect the friction between the belt and the pulley, resulting in slippage; eccentric shaft wear will change the movement parameters of the equipment and affect the crushing effect. Failures of these transmission components will directly lead to a reduction in the speed of the equipment, which in turn affects the crushing efficiency and output. For example, when the belt is loose, the power of the motor cannot be fully transmitted to the working parts of the crusher, and the working efficiency of the equipment will be greatly reduced; after the eccentric shaft is worn, the motion trajectory of the movable jaw will change, and the material cannot be crushed normally.

b. Maintenance strategy

Optimization and adjustment of material characteristics: When the material characteristics change, it is necessary to flexibly adjust the operating parameters of the equipment according to the actual situation. For example, appropriately reduce the feed speed to avoid excessive accumulation of materials in the crushing chamber; reasonably adjust the size of the discharge port to adapt to the change in the particle size of the material. For materials with high humidity, it is possible to consider drying before crushing to improve the fluidity of the material and thus improve the crushing effect. Removing moisture from the material through drying equipment to restore its good fluidity can enable the crusher to crush it better and improve production efficiency.

Timely replacement of jaw plate: Once the jaw plate is found to be severely worn, it should be replaced with a new one immediately. When selecting a new jaw plate, it must be strictly matched according to the equipment model to ensure that its size, material and performance meet the requirements. During the installation process, ensure that the jaw plates are firmly installed and accurately positioned. The jaw plates on the movable jaw and the static jaw should be replaced at the same time to ensure the balanced operation of the equipment. Replacing the jaw plates on both sides at the same time can avoid excessive vibration of the equipment due to uneven crushing force on both sides and ensure stable operation of the equipment.

Cleaning and adjustment of the discharge port: Clean the discharge port regularly to remove accumulated materials and foreign matter. When cleaning, you must stop the machine first, ensure safety, and then use professional tools for cleaning. After cleaning, carefully check whether the size of the discharge port meets the requirements. If necessary, fine-tune it according to the actual situation to ensure that the material can be discharged smoothly. Use special cleaning tools, such as long-handled shovels, hooks, etc., to completely remove the blockage, and then accurately adjust the discharge port according to the particle size and output requirements of the material.

Repair and replacement of transmission parts: For the problem of belt loosening, the belt tension can be restored by adjusting the belt tensioning device; if the pulley is severely worn, a new pulley should be replaced in time to ensure good fit between the belt and the pulley; for eccentric shaft wear, it is necessary to evaluate according to the degree of wear. Mild wear can be repaired by repair technology, such as grinding, surfacing, etc. If the wear is serious, a new eccentric shaft must be replaced. After repairing or replacing the transmission parts, the equipment should be fully tested and the speed, vibration and other parameters of the equipment should be monitored to ensure that the equipment operates normally. Through the trial run, possible problems can be discovered and solved in time to ensure that the equipment can operate stably after it is officially put into use.

Jaw Crusher

2. Troubleshooting and solution of uneven product particle size

a. Root cause of the fault

Uneven wear of the jaw plate: As mentioned above, uneven wear of the jaw plate will cause uneven distribution of the extrusion force and friction force of the material during the crushing process, resulting in inconsistent degree of material crushing, resulting in uneven product particle size. In addition, improper installation of the jaw plate, such as inconsistent gaps between the jaw plate and the movable jaw and the static jaw, will also affect the crushing effect of the material, resulting in large differences in product particle size. Uneven gaps will cause different forces to be applied to the material during crushing, with some places experiencing greater crushing force and others experiencing less crushing force, resulting in products with larger differences in particle size.

Inaccurate adjustment of the discharge port: The size of the discharge port is a key factor in controlling the particle size of the product. If the discharge port is not adjusted evenly, or if the size of the discharge port changes due to vibration or other reasons during the operation of the equipment, the particle size of the material will be inconsistent when it is discharged, resulting in uneven product particle size. Even a slight change in the discharge port may have a significant impact on the product particle size, so it is necessary to regularly check and adjust the discharge port.

Foreign matter mixed into the crushing chamber: If foreign matter such as iron blocks and stones are accidentally mixed into the crushing chamber, these foreign matter will interfere with the normal crushing process of the material, causing the material to be subjected to abnormal forces during crushing, resulting in uneven product particle size. At the same time, foreign matter may also damage the components of the equipment, such as scratching the jaw plate, liner, etc. The presence of foreign matter will not only affect product quality, but may also cause equipment failure and increase maintenance costs.

Abnormal equipment vibration: Excessive equipment vibration is one of the important reasons for uneven product particle size. Excessive vibration may loosen the jaw plate, liner and other components, change the crushing trajectory of the material, and affect the crushing effect. The reasons for excessive vibration of the equipment are more complicated. It may be that the foundation is not solid and cannot effectively support the operation of the equipment; the eccentric shaft is unbalanced, generating a large centrifugal force during the rotation process; the bearing is damaged, resulting in unstable operation of the equipment, etc. Unstable equipment operation will cause the movement of the material in the crushing chamber to lose its regularity and cannot be crushed evenly.

b. Maintenance plan

Jaw plate repair and replacement: For uneven wear of the jaw plate, the appropriate repair method can be selected according to the degree of wear. In case of mild wear, surfacing technology can be used to fill the worn part, and then grinding can be performed to restore it to normal flatness; if the wear is severe, a new jaw plate should be replaced in time. When installing the jaw plate, strictly follow the installation requirements to ensure that the gap between the jaw plate and the movable jaw and static jaw is uniform and consistent, so as to avoid affecting the product particle size due to improper installation. Accurate installation and repair can ensure that the jaw plate has a uniform crushing effect on the material, thereby producing products with consistent particle size.

Recalibration of the discharge port: Carefully check the adjustment device of the discharge port to ensure that it is flexible, reliable and free of jamming. According to the product particle size requirements, use professional tools to accurately adjust the size of the discharge port, and conduct multiple trial runs after adjustment to monitor the changes in product particle size until the product particle size meets the requirements. Through multiple trial runs and adjustments, find the most suitable discharge port size to ensure the stability of product particle size.

Cleaning of foreign matter in the crushing chamber: Once foreign matter is found in the crushing chamber, the machine must be stopped immediately for cleaning. When cleaning, carefully check every corner of the crushing chamber to ensure that foreign matter is completely removed. At the same time, check whether the liner of the crushing chamber is damaged. If damaged, it should be replaced in time to avoid affecting product quality due to liner damage. Comprehensive cleaning and inspection can eliminate the impact of foreign matter on equipment and product quality and ensure the normal operation of the equipment.

Troubleshooting and repair of equipment vibration: Conduct a comprehensive inspection of the foundation of the equipment to check whether the foundation bolts are loose and whether there are cracks in the foundation concrete. If the foundation is found to be unstable, it should be reinforced in time, such as tightening the foundation bolts, repairing cracks, and re-casting the foundation. Check the balance of the eccentric shaft. You can use professional dynamic balancing detection equipment to detect it. If there is any imbalance, dynamic balancing correction should be performed. In the case of bearing damage, replace new bearings in time and choose products with reliable quality. After repairing the vibration problem of the equipment, a long trial run should be carried out to ensure that the equipment runs smoothly and the product particle size is uniform. Through comprehensive troubleshooting and repair, the hidden dangers of equipment vibration are eliminated and the stability of product quality is guaranteed.

Jaw Crusher

3. Tracing and solving the problem of excessive equipment vibration

a. Causes of failure

Poor foundation stability: If the foundation of the jaw crusher is not compacted during construction, or if the foundation bolts are loosened due to vibration during long-term use, it will cause the equipment to vibrate greatly during operation. An unstable foundation may also cause the equipment to shift during operation, affecting the normal operation of the equipment and even causing damage to the equipment. An unstable foundation cannot provide solid support for the equipment. The equipment will shake during operation, aggravating the wear of parts and shortening the service life of the equipment.

Eccentric shaft imbalance: The eccentric shaft is the core transmission component of the jaw crusher. During long-term high-speed rotation, due to the impact, wear and fatigue of the material, the mass distribution of the eccentric shaft may be uneven, resulting in imbalance. The imbalance of the eccentric shaft will generate periodic centrifugal force during rotation, causing the equipment to vibrate violently. This vibration will not only affect the normal operation of the equipment, but also interfere with the surrounding working environment.

Bearing damage: As a key component supporting the eccentric shaft and the movable jaw, the performance of the bearing directly affects the operating stability of the equipment. If the bearing is poorly lubricated during use and cannot form an effective oil film, resulting in increased friction; or if it is overloaded and subjected to excessive load; or if it is fatigued and damaged due to long-term use, the rolling element and raceway of the bearing will be worn and deformed, resulting in stagnation during the operation of the equipment, which will cause excessive vibration. The damaged bearing cannot normally support and guide the rotation of the eccentric shaft, which will cause abnormal operation of the equipment.

Loose parts: Some parts of the crusher, such as jaw plates, liners, flywheels, etc., may become loose during the long-term operation of the equipment due to external forces such as vibration and impact. Loose parts will destroy the overall structural stability of the equipment and cause abnormal vibration of the equipment during operation. The reason for the loosening of parts may be that the bolts are not tightened during installation, or the bolts gradually loosen due to vibration during use. Loose parts will generate additional impact force during the operation of the equipment, aggravating the vibration of the equipment.

b. Maintenance measures

Foundation reinforcement: Conduct a comprehensive inspection of the foundation of the equipment and check whether the foundation bolts are loose one by one. If they are loose, they should be tightened with professional tools according to the specified torque. For the case of a weak foundation, grouting can be used for reinforcement. First, clean the surface of the foundation, and then pour the prepared grouting material into the gap between the foundation and the base of the equipment to fill it densely and enhance the connection strength between the foundation and the equipment. After the reinforcement is completed, the equipment should be reinstalled and debugged to ensure that the installation level of the equipment meets the requirements and avoid vibration caused by the tilt of the equipment. Through precise installation and debugging, the equipment is ensured to operate on a stable basis and reduce the generation of vibration.

Eccentric shaft correction: Carefully remove the eccentric shaft from the equipment and use high-precision dynamic balancing detection equipment to perform dynamic balancing detection on it. According to the test results, determine the imbalance amount and imbalance position of the eccentric shaft, and then use the method of weight removal or counterweight to correct it. For severely worn eccentric shafts, if the balance requirements cannot be achieved through repair, a new eccentric shaft should be replaced in time. When installing the eccentric shaft, strictly follow the installation drawings to ensure that its installation position and direction are accurate to avoid the eccentric shaft being unbalanced again due to improper installation. Accurate correction and installation can ensure the stable rotation of the eccentric shaft and reduce equipment vibration.

Bearing replacement: When the bearing is damaged, a new bearing should be replaced in time. When selecting a new bearing, select the appropriate model and specification according to the model and working requirements of the equipment, and ensure that the quality of the bearing is reliable. When replacing the bearing, pay attention to the installation method to avoid damage to the bearing due to improper installation. After the installation is completed, the bearing should be properly preloaded and the bearing clearance should be adjusted to ensure that the bearing can operate normally. At the same time, it is necessary to strengthen the lubrication management of the bearings, regularly check the lubrication conditions, and replenish or replace the grease in time. Correct bearing replacement and lubrication management can ensure the normal operation of the bearings and improve the operating stability of the equipment.

Tightening of parts: Conduct a comprehensive inspection of the various parts of the crusher, and check one by one whether the connecting bolts of the jaw plate, liner, flywheel and other parts are loose. If there is any looseness, use a torque wrench to tighten it according to the specified torque to ensure that the bolts are tightened reliably. At the same time, check whether the installation of the parts is correct, such as the installation angle of the jaw plate, the fit of the liner, etc. If there is a problem, it should be adjusted in time to ensure that the installation of the parts meets the requirements and avoid equipment vibration due to loose or improper installation of parts. Comprehensive inspection and tightening can ensure the overall structural stability of the equipment and reduce the occurrence of vibration.

Jaw Crusher

4. Analysis and solution of the problem of excessive bearing temperature

a. Fault factors

Poor lubrication: Good lubrication of bearings is the key to ensure their normal operation. If the grease is insufficient, an effective lubricating film cannot be formed between the rolling elements and raceways of the bearing, which will increase the friction of the bearing and generate a lot of heat, thereby increasing the bearing temperature. Grease deterioration is also one of the common causes of poor lubrication. For example, after long-term use of grease, it loses its lubricating properties due to oxidation, contamination and other reasons, and cannot play an effective lubricating role. In addition, improper lubrication methods, such as excessive or insufficient oiling, unreasonable oiling time intervals, etc., will also affect the lubrication effect of the bearing and cause abnormally high bearing temperature. Inappropriate lubrication methods will break the lubrication balance inside the bearing, increase friction, and then cause a temperature surge. For example, excessive oiling will cause excess grease to stir inside the bearing, which will not only fail to play a good lubricating role, but also generate additional heat; too little oiling will make it difficult to form a complete lubricating film, resulting in direct contact and friction between metal parts.

Improper bearing installation: The installation accuracy of the bearing has a vital impact on its operating performance. If the bearing is installed too tightly, the internal clearance of the bearing will be reduced, resulting in uneven force on the bearing during operation, increased local friction, and thus temperature rise. Overtight installation will cause excessive pressure on the internal structure of the bearing, accelerate wear, and generate more heat. On the contrary, if the bearing is installed too loosely, the bearing will shake during operation and cannot bear the load normally, which will also cause temperature rise. Loosely installed bearings cannot stably support the eccentric shaft and movable jaw. During the operation of the equipment, they will frequently rub due to unstable force, resulting in abnormal temperature. In addition, incorrect installation position of the bearing, such as insufficient matching accuracy between the bearing and the shaft or the bearing seat, will also affect the normal operation of the bearing and cause temperature rise. Inaccurate installation position will cause the bearing to deviate from the normal trajectory during operation, increase friction loss, and ultimately reflect as temperature rise.

Overload: When the jaw crusher is in an overloaded operation state for a long time, the load on the bearing will far exceed its designed load-bearing capacity, resulting in uneven stress distribution inside the bearing, increased friction, and a sharp increase in bearing temperature. The reason for excessive load may be too much feed, the crusher needs to process a large amount of material in a short time; the material hardness is too large, which exceeds the crushing capacity of the equipment, so that the equipment needs to consume more energy during the crushing process, thereby increasing the load on the bearing. Long-term overload operation is like letting the bearing bear a burden beyond its bearing capacity, and continuous high-intensity work will inevitably cause it to overheat.

Poor heat dissipation: The bearing will generate a certain amount of heat during operation, which needs to be dissipated in time to ensure the normal working temperature of the bearing. If the heat dissipation conditions of the bearing are not good, such as the heat sink of the bearing seat is damaged, the heat cannot be effectively transferred out; the ventilation around the equipment is not smooth, and the heat cannot be dissipated to the surrounding environment in time, which will cause the heat generated by the bearing to accumulate continuously, thereby increasing the bearing temperature. The heat sink is like the "heat dissipation guard" of the bearing. Once damaged, the heat is difficult to conduct effectively; and poor ventilation is like covering the equipment with a layer of "heat shield", the heat is trapped inside and cannot dissipate. Over time, the bearing temperature will continue to rise.

Jaw Crusher

b. Maintenance countermeasures

Optimization of lubrication conditions: Establish a system for regular inspection of bearing lubrication conditions, and regularly replenish or replace grease according to the use requirements of the equipment. When choosing grease, it is necessary to select grease with good high temperature resistance and wear resistance according to the operating environment and working conditions of the equipment. For example, for jaw crushers operating in high temperature environments, high temperature resistant lithium-based grease should be selected to ensure that good lubrication performance can be maintained at high temperatures. At the same time, improve the lubrication method, adopt a reasonable oiling method and oiling time interval, and ensure that the grease can be evenly distributed in various parts of the bearing to form an effective lubricating film. Professional lubrication tools, such as quantitative oilers, can be used to achieve accurate oiling of the bearing to avoid lubrication problems caused by improper oiling.

Bearing reinstallation: If the bearing is found to be improperly installed, the bearing should be carefully disassembled and reinstalled. During the installation process, it is necessary to strictly follow the operating procedures and use professional installation tools, such as bearing installation sleeves, presses, etc., to ensure that the installation accuracy of the bearing meets the requirements. After the installation is completed, the bearing should be properly adjusted, such as adjusting the bearing clearance, preload, etc., to make it run smoothly. Use professional measuring tools, such as feeler gauges, micrometers, etc., to accurately adjust the bearing clearance and preload to ensure that the bearing runs in the best condition. At the same time, the installation position of the bearing should be checked to ensure that the matching accuracy between the bearing, shaft and bearing seat meets the requirements.

Reasonable load adjustment: Pay close attention to the operation of the equipment, and reasonably adjust the feed amount and material particle size according to the rated load of the equipment and actual production needs. To avoid long-term overload operation of the equipment, you can install a feed control device, such as the variable frequency speed regulation system of the vibrating feeder, to achieve precise control of the feed amount. For materials with higher hardness, you can consider using a multi-stage crushing method, first crush the material preliminarily to reduce its hardness and particle size, and then enter the jaw crusher for secondary crushing, thereby reducing the load of the equipment and reducing the wear and heat of the bearing. Through scientific process design, the equipment can be operated within a reasonable load range, which can not only ensure production efficiency but also extend the service life of the equipment.

Improvement of heat dissipation conditions: Regularly check whether the heat sink of the bearing seat is intact. If damaged, it should be repaired or replaced in time. Ensure that the surface of the heat sink is clean and free of dust, oil and other debris to ensure the heat dissipation effect of the heat sink. Compressed air or high-pressure water guns can be used to clean the heat sink to remove surface dirt. At the same time, to ensure good ventilation around the equipment, ventilation ducts can be set around the equipment or auxiliary heat dissipation equipment such as cooling fans can be installed to enhance air circulation and improve the heat dissipation efficiency of the bearing. In addition, the bearing seat can be improved by using materials or structures with better heat dissipation performance to further improve the heat dissipation capacity of the bearing. For example, the traditional cast iron bearing seat can be replaced with an aluminum alloy bearing seat, and the good thermal conductivity of aluminum alloy can be used to accelerate the heat dissipation.

Jaw Crusher

PS: The significance of jaw crusher fault repair is to ensure stable operation of the equipment and improve production efficiency. When a jaw crusher fails, timely repair can prevent the failure from expanding, reduce downtime, and avoid production delays caused by equipment problems. Effective fault repair can extend the service life of the crusher, reduce the frequency of equipment replacement, and thus save the company's operating costs. At the same time, regular maintenance and repair can also improve the crushing efficiency of the crusher, ensure product quality, and enhance the competitiveness of the company.

Save Time! Get A Detailed Quotation Quickly.