Preface: Eddy current separator is a highly efficient nonferrous metal recycling equipment, which works based on the principle of electromagnetic induction. It uses high-frequency alternating magnetic field to generate eddy current inside the metal, and separates the metal through the interaction between eddy current and original magnetic field. Eddy current separator has the advantages of high sorting efficiency, strong adaptability, reliable mechanical structure, energy saving and environmental protection, and is widely used in scrap metal recycling, mineral processing, metallurgy and other fields. With the continuous advancement of technology, the application field of eddy current separator will be further expanded, and the level of intelligence and automation will continue to improve. The following is a detailed introduction to its working principle and application scenarios:

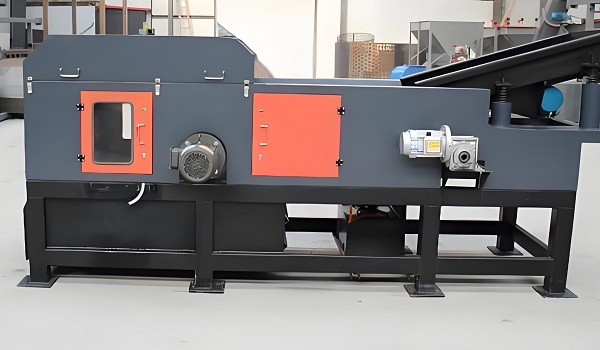

Eddy Current Separator

A. Working principle of eddy current separator

The working principle of eddy current separator is based on the physical phenomenon that conductors generate eddy currents in high-frequency alternating magnetic fields. When a metal object enters a high-frequency alternating magnetic field, eddy currents will be generated inside it. The eddy current itself will generate a magnetic field in the opposite direction of the original magnetic field, and this anti-magnetic field will generate a mutually repulsive force with the original magnetic field, namely the Lorentz force. This repulsive force will separate the metal object from the material flow, thereby achieving effective separation of metal and non-metal.

The eddy current separator is usually equipped with one or more magnetic rollers, and the surface of the magnetic roller generates a high-frequency alternating strong magnetic field. When materials containing non-magnetic conductive metals (such as copper, aluminum, etc.) pass through the magnetic field at a certain speed, induced eddy currents will be generated in these metals. Since the material flow and the magnetic field have a relative motion speed, there is a thrust on the metal sheets and blocks that generate eddy currents, so that they are separated from the material flow.

Eddy Current Separator

B. Application scenarios of eddy current separators

Eddy current separators have a wide range of application scenarios, mainly including the following aspects:

1. Scrap metal recycling: Eddy current separators can separate valuable non-ferrous metals such as aluminum and copper from scrap metals to achieve resource recycling.

2. Garbage classification: In the treatment of urban domestic waste, eddy current separators can separate non-ferrous metals such as aluminum cans and bottle caps, improve resource recycling rate, and reduce the amount of landfill.

3. Mining and metallurgy: In the field of mining and metallurgy, eddy current separators can be used for the recovery and reuse of tailings, as well as the treatment of concentrates, to improve the comprehensive utilization rate of resources.

Eddy Current Separator

4. Electronic waste treatment: With the popularization of electronic products and the acceleration of replacement speed, the treatment of electronic waste (i.e. "electronic waste") has become an urgent problem to be solved. Eddy current separators can separate non-ferrous metals from old household appliances (such as refrigerators, air conditioners, televisions, computers, etc.), circuit boards and other electronic waste to achieve resource recycling and reuse.

PS: Eddy current separators play an important role in the field of metal sorting and resource recycling with their unique working principle and wide application scenarios.

Save Time! Get A Detailed Quotation Quickly.