Introduction: Domestic waste sorting equipment is widely used in urban solid waste treatment centers, community waste sorting stations, commercial areas and public places. They can not only improve the efficiency of waste sorting, but also reduce the labor intensity of manual sorting and improve the overall waste treatment capacity. Choosing high-quality domestic waste sorting equipment is a decision-making process involving many factors. Here are some key considerations to help make a wise choice:

Waste Sorting Equipment-Trommel Screen

A. Clarify the types of waste to be sorted and the sorting requirements

1. Types of waste: First, determine the types of waste to be processed, including the quantity, composition, special requirements, etc. of the waste. This helps to choose the right sorting equipment, because different types of waste may require different sorting techniques and equipment.

2. Sorting requirements: Consider sorting efficiency, accuracy, environmental protection and other requirements. Efficient sorting equipment can process a large amount of waste in a short time and improve the efficiency of waste treatment. High-precision sorting equipment can accurately identify and sort different types of waste, reducing misjudgment and mixing. At the same time, environmental protection requirements are also a factor that cannot be ignored when choosing equipment.

Waste Sorting Equipment-Wind Sifter

B. Consider the performance and parameters of domestic waste sorting equipment

1. Sorting speed: an important indicator to measure the efficiency of waste sorting equipment, usually expressed in terms of the amount of waste sorted per hour. High-speed sorting equipment can meet the needs of large-scale waste treatment sites.

2. Sorting accuracy: the ability of the equipment to accurately identify and sort different types of garbage. High-precision sorting equipment can distinguish garbage of various shapes, sizes, colors and materials.

3. Adaptability: The equipment needs to be able to adapt to garbage of different sizes, shapes, materials, and garbage of different humidity, viscosity and other conditions. Good adaptability can avoid blockage and failure.

4. Stability: The equipment needs to maintain stable performance during long-term operation to avoid frequent failures and downtime. Stable equipment can ensure the continuity of garbage treatment and improve work efficiency.

5. Automation: The higher the degree of automation of the equipment, the easier it is to operate and the higher the efficiency. Automated equipment can realize automatic identification, automatic sorting and automatic transmission of garbage through sensors, cameras and other technologies, reducing human intervention.

6. Energy consumption: Low-energy consumption equipment can reduce operating costs and also meet the requirements of energy conservation and environmental protection. When choosing, you can consider equipment that uses energy-saving technology, such as variable frequency speed regulation, intelligent control, etc.

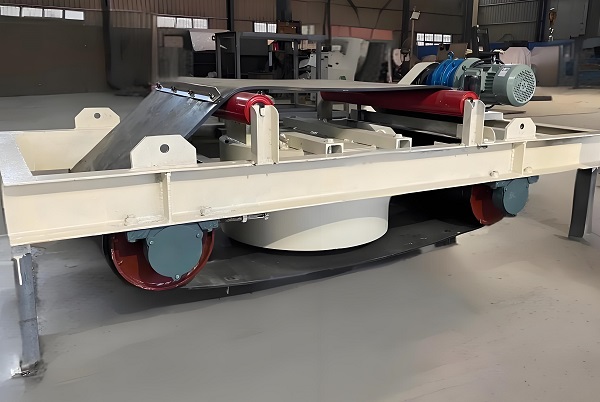

Waste Sorting Equipment-Magnetic Separator

C. Consider the price and quality of domestic waste sorting equipment

1. Price factor: Compare product quotations from different manufacturers and make reasonable choices based on cost performance.

2. Product quality: Investigate whether the equipment provided by the manufacturer has passed the relevant quality certification and whether it has a good market reputation.

D. Consider the R&D capabilities and manufacturing processes of the equipment manufacturer

1. Design rationality: The design of the equipment should take into account the characteristics of the waste, such as size, weight, composition, etc., to ensure that the equipment can effectively handle the target waste. At the same time, a reasonable design also includes considerations such as the ease of use, maintenance cost and service life of the equipment.

2. Material selection: Since garbage sorting equipment often comes into contact with various corrosive or abrasive materials, the selected materials must have good corrosion resistance and wear resistance. Commonly used materials include stainless steel, high-strength alloy steel, etc.

3. Technical R&D capabilities: Understand whether the manufacturer has a strong R&D team and whether it can provide advanced technology and innovative solutions.

4. Manufacturing process: High-quality manufacturing process is the basis for ensuring equipment performance. Including precision machining, welding technology, surface treatment and other links. Quality standards need to be strictly enforced during the manufacturing process to ensure that each component meets the design requirements.

E. Consider the after-sales service and support of the equipment manufacturer

1. After-sales service system: Understand whether the manufacturer can provide comprehensive after-sales service, including technical support, repair and maintenance, etc. Choose a manufacturer that provides a comprehensive after-sales service system, such as regular maintenance services, quick response mechanisms for faults, etc. This helps to ensure the long-term stable operation of the equipment.

2. Technical support and training: The manufacturer should provide necessary technical support and training to help operators become familiar with the use and maintenance methods of the equipment.

Waste Sorting Equipment-Eddy current separator

F. Consider the application cases and word-of-mouth evaluation of the equipment

1. Customer cases: Check the manufacturer's past customer cases to evaluate its project implementation capabilities and experience. Understand the manufacturer's successful cases in other similar projects, which will help evaluate the actual effect and performance of the equipment.

2. Word-of-mouth evaluation: Understand the user's evaluation and feedback on the equipment through industry forums, social media and other channels, which will help to understand the advantages and disadvantages of the equipment more comprehensively.

PS: Choosing a high-quality manufacturer of domestic waste sorting equipment is the key to ensuring equipment quality and service. Choosing high-quality household waste sorting equipment requires comprehensive consideration of multiple factors, including waste type and sorting requirements, equipment performance and parameters, equipment quality and manufacturing process, after-sales service and support, as well as actual cases and word-of-mouth evaluation. By comprehensively evaluating these factors, you can make a more informed choice.

Save Time! Get A Detailed Quotation Quickly.