The following matters need to be noted during the operation of the magnetic separator to ensure its safe and efficient operation:

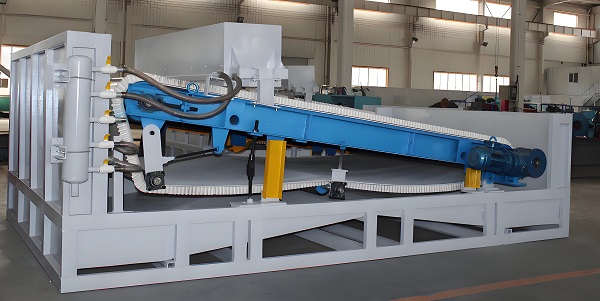

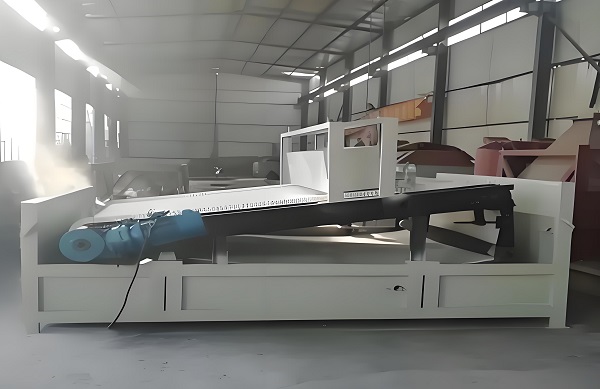

Magnetic Separator

1. Inspection and preparation before driving

Inspect the equipment thoroughly: Before driving, the magnetic separator should be thoroughly inspected, including power lines, transmission devices, lubrication systems, feed pipes, distribution barrels, feed boxes, receiving boxes, flushing pipes and other equipment components to ensure that they are in good condition and no debris falls into the machine slot.

Clean pipes and drums: Clean the pipes of the magnetic separator, check whether the drums are stuck or rubbed, and ensure that the discharge ports of concentrates and tailings are smooth.

Check the motor and belt: Check whether the motor belt is intact, whether it is damaged or loose, and ensure that the motor can operate normally.

Magnetic Separator

2. Precautions during driving and operation

Drive in sequence: The driving of the equipment should be carried out in a certain order. Generally speaking, the driving is from back to front according to the process, and the parking is the opposite. When driving, first open the water pipes of each part of the equipment. The discharge port should be small at the beginning, then feed the ore, and gradually adjust to normal operation.

Observe the operating status: During the operation of the magnetic separator, always pay attention to whether the temperature and sound of the motor, reducer and other rotating parts are normal, and whether the operation is stable. If there are abnormal conditions such as temperature rise and loud noise, the machine should be stopped in time for inspection and treatment.

Check the discharge: Check the discharge of concentrate and tailings frequently to ensure smooth discharge without blockage. At the same time, according to the quality and discharge of concentrate and tailings, adjust the magnetic declination and working gap appropriately to ensure the recovery rate of magnetite.

Do not touch the rotating parts: When the magnetic separator is running, do not touch the rotating parts. If any problems are found, stop the machine and then deal with them.

3. Maintenance after parking and shutdown

Stop in order: When stopping, contact the pump manager first, then stop feeding, wait until the material in the dilute medium bin is processed and the magnetic separator can no longer select magnetite powder, and then gradually close the water gate and discharge port. Partial parking should also be contacted in advance to determine the number of pumps to be started. After parking, the equipment should be inspected comprehensively, and the coal sludge and other debris accumulated in the feed box and tailings box should be cleaned to prepare for the next start.

Inspection and maintenance: After parking, check whether the components of the magnetic separator are intact and whether there is any wear or damage. At the same time, necessary maintenance work should be carried out on the equipment, such as injecting lubricants and replacing worn parts.

Magnetic Separator

4. Safety operating procedures

It is strictly forbidden to start and stop the equipment with load: When starting or stopping the magnetic separator, it is strictly forbidden to operate with load to avoid damage to the equipment or cause safety accidents.

It is forbidden to overhaul the equipment while it is running: It is strictly forbidden to overhaul or clean the sanitation work during the operation of the magnetic separator to avoid accidents.

Protect the surface of the drum: Check the drum part frequently to prevent other ironware or tools from being adsorbed on the drum and causing damage to the equipment. At the same time, prevent sharp objects from scratching the surface of the drum.

PS: The magnetic separator needs to pay attention to many aspects during operation to ensure its safe and efficient operation. Operators should strictly abide by the operating procedures and safety regulations, strengthen the inspection and maintenance of the equipment, and promptly discover and deal with abnormal situations.

Save Time! Get A Detailed Quotation Quickly.