Preface: Magnetic separators are widely used in many fields such as mineral processing, mining, and environmental protection. The stability and efficiency of their operation directly affect the quality and efficiency of production. Correct installation and scientific maintenance are the key to ensuring the good performance of magnetic separators. This article will elaborate on the installation and maintenance points of magnetic separators.

A. Preparation before installation of magnetic separators

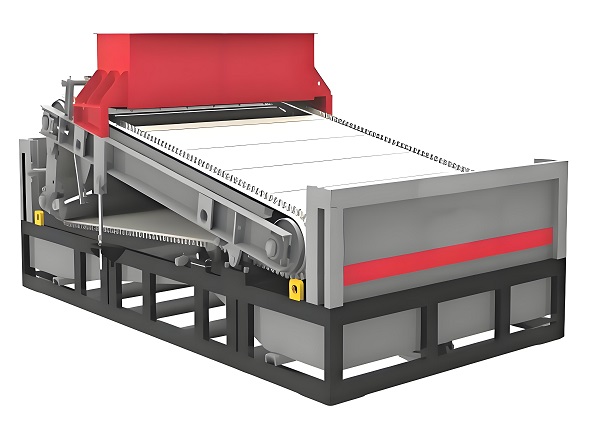

Magnetic Separator

1. Equipment inspection: After the magnetic separator arrives, carefully check the various components of the equipment according to the delivery list to check whether there are any missing or damaged parts. Focus on checking whether the magnetism of the magnetic system is normal and whether the cylinder has deformation, scratches, etc.

2. Foundation design and construction: Design a reasonable foundation according to the installation size and weight of the magnetic separator. The foundation should have sufficient strength and stability to withstand the vibration and weight of the equipment during operation. During the construction process, the flatness of the foundation surface should be ensured, the horizontal error should be controlled within the specified range, and the anchor bolt holes should be reserved.

3. Installation tools and material preparation: Prepare various tools required for installation, such as wrenches, cranes, levels, etc. At the same time, prepare installation materials such as anchor bolts, gaskets, and lubricating oil.

B. Installation steps of magnetic separator

Magnetic Separator

1. Base installation: Place the base of the magnetic separator on the foundation and use anchor bolts for preliminary fixation. Use a level to adjust the level of the base to the accuracy required by the equipment, and then tighten the anchor bolts to ensure that the base is firmly fixed.

2. Magnetic system installation: Carefully install the magnetic system on the base, and pay attention to the installation direction and position of the magnetic system to be accurate. Avoid collision with the magnetic system during installation to prevent weakening of magnetism or damage to the magnetic system structure. After installation, check whether the connection between the magnetic system and the base is tight.

3. Cylinder installation: Use a crane to smoothly cover the cylinder on the magnetic system, and pay attention to the uniform gap between the cylinder and the magnetic system. After installation, check the rotation flexibility of the cylinder to ensure that the cylinder does not rub against other parts during rotation.

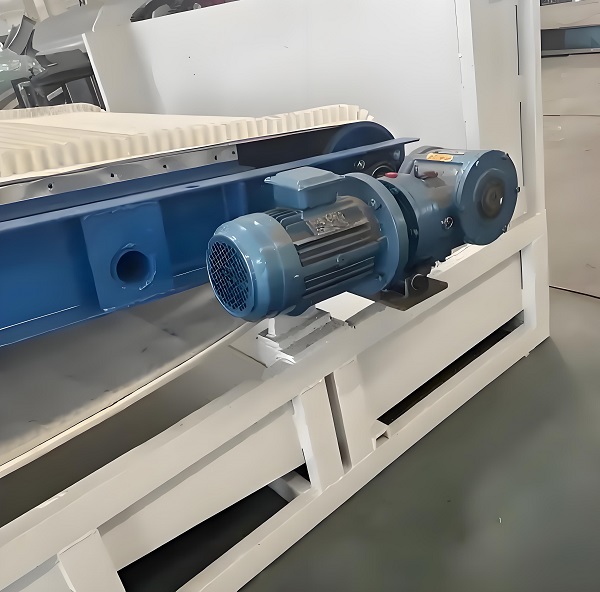

4. Transmission device installation: Install the transmission device in a suitable position, connect the motor and reducer, and then connect the reducer to the transmission shaft of the cylinder. Adjust the position of the transmission device to ensure that the tension of the belt or chain is moderate, and avoid being too loose or too tight to affect the transmission efficiency and equipment life.

5. Installation of feeding and discharging devices: When installing the feeding device, ensure that the ore is fed evenly to avoid the phenomenon of ore bias that affects the magnetic separation effect. The installation of the discharging device must ensure smooth ore discharge and avoid slurry blockage. At the same time, install the relevant pipes and valves to ensure the continuity of the entire process.

C. Maintenance points of magnetic separator

Magnetic Separator

1. Daily inspection: Perform daily inspections on the magnetic separator every day to observe the operating status of the equipment, including whether the rotation of the cylinder is stable, whether there is abnormal noise, whether the belt or chain of the transmission device is loose or worn, and whether the connection parts are firm. Check whether the magnetic field strength of the magnetic separator is normal, and find and deal with problems in time.

2. Regular lubrication: Lubricate each lubrication point regularly according to the lubrication requirements of the equipment. Choose appropriate lubricating oil or grease to ensure the lubrication effect. Generally speaking, bearings, reducers and other parts of the transmission device need to be regularly greased, while chains need to be regularly lubricated.

3. Cleaning and maintenance: Clean the magnetic separator regularly to remove the slurry and impurities on the surface and inside of the cylinder. Especially when dealing with viscous ores, more attention should be paid to cleaning to prevent the slurry from attaching and affecting the magnetic separation effect. At the same time, the vulnerable parts of the equipment, such as belts, chains, bearings, etc., should be checked and replaced regularly.

4. Magnetic system maintenance: Although the magnetic system generally does not require frequent maintenance, it is also necessary to regularly check whether its magnetism has changed. Avoid violent collisions and high temperatures to prevent the magnetism from weakening. If the magnetism of the magnetic system is found to have dropped significantly, analyze the reasons in time and take corresponding measures, such as replacing magnetic blocks.

D. Common faults and solutions of magnetic separators

Magnetic Separator

1. Poor magnetic separation effect: It may be caused by insufficient magnetic field strength, excessive or uneven feed, inappropriate slurry concentration, etc. The solution is to check the magnetic system, adjust the magnetic field strength; reasonably control the feed amount and feed uniformity; adjust the slurry concentration to the appropriate range.

2. Excessive vibration of the equipment: It may be caused by unstable foundation, loose anchor bolts, unbalanced cylinder, etc. The treatment method is to check the foundation and anchor bolts, re-tighten them; perform dynamic balance test and adjustment on the cylinder.

3. Transmission device failure: such as belt slippage, chain breakage, etc. Belt slippage may be due to insufficient tension or belt wear, and the tension can be adjusted or the belt can be replaced; chain breakage may be due to chain fatigue or poor lubrication, and the chain can be replaced and lubrication can be strengthened.

PS: The correct installation and scientific maintenance of the magnetic separator are the key to ensuring its efficient and stable operation. During the installation process, the steps and requirements must be strictly followed to ensure the accuracy of equipment installation. In daily use, maintenance work must be done well, problems must be discovered and solved in a timely manner, the service life of the equipment must be extended, and production efficiency must be improved. Only in this way can the important role of magnetic separators in various fields be fully utilized to create greater economic benefits for enterprises.

Save Time! Get A Detailed Quotation Quickly.