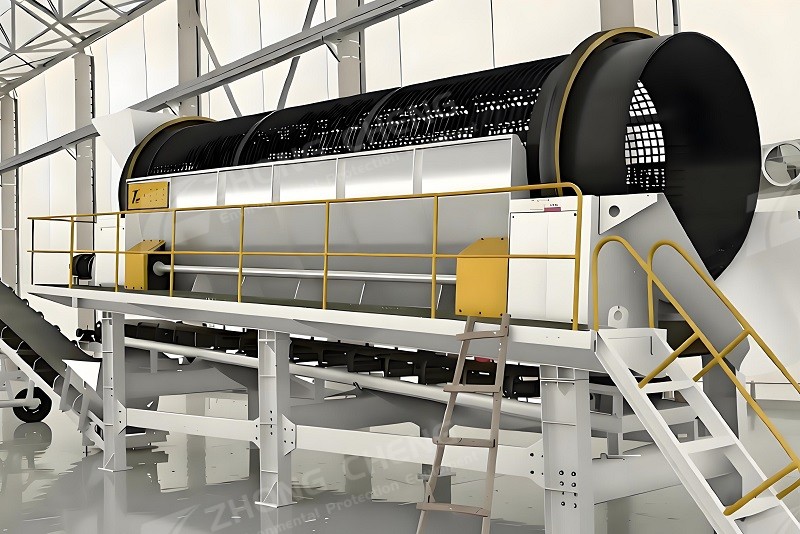

In the initial stages of waste harmless treatment and resource utilization, the adaptability of screening equipment directly impacts the effectiveness of subsequent processing. Rotary trommel screens, with their flexible structure, anti-clogging properties, and resistance to material adhesion, have become a core piece of equipment in various waste pretreatment processes, offering a wide range of applications. Based on the working principle of inclined rotating screens, combined with centrifugal force and the self-weight of the material, they can accurately separate waste of different particle sizes. They are particularly suitable for mixed waste with complex composition, a wide range of particle sizes, and fluctuating moisture content, efficiently adapting to various scenarios such as fresh municipal solid waste and aged waste, empowering subsequent resource recovery, incineration, or landfill processes, and serving as a key piece of equipment in promoting waste reduction and utilization.

As the system for harmless treatment and resource utilization of municipal solid waste continues to improve, the adaptability of front-end screening equipment directly determines the efficiency of subsequent processing and the quality of resource recovery. Rotary trommel screens, with their core advantages of flexible structure, resistance to clogging, and stable operation, have become the mainstream equipment for various waste pretreatment processes. They are particularly suitable for processing mixed waste with complex composition, large particle size differences, and a wide range of moisture content fluctuations, enabling precise grading for different types of waste and adapting to multi-scenario waste treatment needs. They are a key piece of equipment in promoting waste reduction and resource utilization. Their adaptability mainly relies on the screen drum structure design, rotation speed control, and auxiliary anti-clogging systems, covering various types of waste such as fresh waste, aged waste, and construction waste, while balancing screening accuracy and processing efficiency.

The most crucial application scenario for rotary trommel screens is urban municipal solid waste. This type of waste has a complex composition and a wide range of particle sizes, including food waste, recyclables, and other waste, which perfectly matches the multi-stage screening and anti-clogging characteristics of rotary trommel screens. Fresh municipal solid waste accounts for the largest proportion of urban solid waste, and its components include food scraps, plastic fragments, paper, glass, bricks, textiles, etc., with particle sizes ranging from a few millimeters to tens of centimeters, and a moisture content usually between 30% and 60%, which can easily lead to material adhesion and screen clogging. Rotary trommel screens, through their shaftless design, avoid entanglement of long-shaped materials, and utilize segmented screens to achieve "small first, then large" grading. Combined with spray cleaning and mechanical brushing devices, they can effectively process this type of mixed waste, separating materials of different particle sizes. From the perspective of specific components, rotary screens can efficiently screen fine-grained materials in fresh municipal solid waste. These materials mainly include food waste fragments, fine soil, and powdery debris, with particle sizes typically below 10-20 mm. Food waste, as a major component of fresh municipal solid waste, accounts for 40%-60% and mainly consists of vegetable leaves, fruit peels, and leftover food. It is soft in texture, has high moisture content, and is prone to clumping. The low-speed rotation (3-8 revolutions/minute) of the rotary screen prevents material from being crushed, while the lifting plates cause the material to tumble, allowing fine-grained food waste fragments to fully contact the screen surface and be separated through the screen holes. The separated fine materials can be directly used for biological composting or anaerobic digestion, achieving resource utilization. Larger food waste fragments can be conveyed along the screen drum to subsequent crushing stages for secondary processing and resource recovery.

In addition to fine-grained materials, rotary screens are also suitable for screening medium-sized municipal solid waste, with particle sizes between 20-100 mm. These materials mainly include small plastic bottles, paper fragments, small pieces of wood, glass fragments, and small bricks and stones. These materials have diverse textures, including flexible plastics and paper, as well as rigid glass and bricks. Traditional screening equipment often experiences clogging or incomplete sorting problems. The rotary screen uses corrosion-resistant and wear-resistant screen plates with adjustable aperture sizes. The 30-50 mm and 80-100 mm screen sections designed for medium-sized materials can achieve precise classification: lightweight medium-sized materials such as plastics and paper can enter subsequent air separation stages for separation and recycling, while heavier materials such as glass and bricks can be collected separately for building material processing or harmless landfill.

Aged waste is also one of the suitable types for rotary screens. This type of waste consists mostly of municipal solid waste that has been stockpiled for a long time. After microbial degradation, its composition differs from fresh waste, mainly including humus soil, broken plastics, aged fabrics, and calcified debris. The overall particle size is smaller, and the moisture content is lower, with weaker adhesion. The trommel screen can be adjusted to the characteristics of aged waste by modifying the screen mesh size and rotation speed, achieving efficient separation of humus from other impurities: humus with a particle size of less than 10mm can pass through the screen mesh and, after harmless treatment, be used for landscaping and soil improvement, realizing resource recycling; impurities such as plastics and fabrics that do not pass through the screen mesh can be further sorted for recycling or incineration, significantly improving the resource utilization rate of aged waste and avoiding environmental pollution caused by long-term accumulation.

The trommel screen can also be adapted to some construction and demolition waste. This type of waste has a relatively simple composition, mainly including crushed stone, sand, cement blocks, broken tiles, and wood chips. It has a large particle size range and is mostly composed of rigid materials with strong abrasive properties. For this type of waste, the trommel screen can use thickened, wear-resistant screen plates and a large-aperture segmented screen mesh (50-200mm). By adjusting the installation angle and rotation speed, it can achieve the classification of materials of different particle sizes: fine-grained materials such as sand and fine crushed stone can pass through the screen mesh and be used for concrete aggregate, road base materials, and other building materials; medium and large materials such as cement blocks and tiles can be collected separately and reused after crushing; and lightweight materials such as wood chips can be separated and used for biomass power generation, balancing processing efficiency and resource recovery. It should be noted that rebar and large metal components in construction waste must be removed in advance to avoid damaging the screen drum and equipment components.

In addition, the trommel screen can be adapted to some industrial light waste, such as plastic scraps, foam fragments, paper scraps, and fiber waste. This type of waste is lightweight, has a uniform particle size, is not prone to clogging the screen mesh, and is not highly corrosive. It can be classified and separated using a trommel screen. For example, plastic scraps from plastic processing plants can be separated into different sizes of fragments using a trommel screen, facilitating subsequent crushing and reprocessing; mixtures of foam fragments and paper scraps can be classified by a trommel screen and then separated and recycled through air separation, improving the purity of resource recovery. However, highly corrosive and high-hardness industrial waste, such as waste acid, waste alkali, and metal slag, should be avoided, as these types of waste will damage the screen plates and equipment components, affecting the service life of the equipment. It's important to clarify that while trommel screens have a wide range of applications, not all types of waste are suitable for screening. For oversized waste, such as discarded furniture, appliances, and large pieces of brick and stone, manual or mechanical sorting is required beforehand to prevent them from entering the screen drum and causing blockages or equipment damage. Highly viscous and corrosive waste, such as waste paint, asphalt waste, and chemical sludge, can severely clog the screen holes and corrode the screen plates, making trommel screening unsuitable. Flammable and explosive waste, such as waste batteries and gasoline cans, must be handled separately and are prohibited from entering the trommel screen to prevent safety hazards.

The adaptability of the trommel screen can be further optimized through parameter adjustments. By flexibly adjusting the screen hole size, drum rotation speed, and installation angle according to the characteristics of different types of waste, screening efficiency and accuracy can be significantly improved. For example, when processing fresh waste with high moisture content, the rotation speed can be reduced and the inclination angle decreased to extend the material's residence time, and a spray cleaning device can be used to prevent clogging. When processing aged waste, the rotation speed can be increased and the screen holes adjusted to improve the classification speed. When processing construction waste, thicker screen plates and larger apertures can be selected to accommodate high wear requirements. This flexible adjustment capability allows the trommel screen to adapt to different scenarios and types of waste screening needs, making it a core piece of equipment in the waste pretreatment process.

Trommel screens are suitable for urban fresh household waste, aged waste, some construction waste, and light industrial waste. Their core advantage lies in their ability to process mixed waste with complex compositions and uneven particle sizes, achieving precise classification through flexible parameter adjustments. It avoids the processing risks associated with highly viscous and corrosive waste, and its structural design reduces equipment wear, balancing efficiency and environmental protection. As a core piece of equipment in waste pretreatment, its widespread application effectively improves the resource utilization rate of waste, connects subsequent processing steps, and provides solid support for building a green and sustainable waste treatment system.

Save Time! Get A Detailed Quotation Quickly.