A single-shaft shredder is a highly efficient solid waste treatment device, with a single rotating blade shaft as its core working component. Multiple sets of staggered blades are mounted on the shaft, creating a shear gap with the fixed blades. A motor drives the shaft to rotate at high speed, tearing, shearing, and crushing the material.

A single-shaft shredder is a highly efficient solid waste treatment device, centered around a single rotating blade shaft. Multiple sets of staggered blades are mounted on the shaft, creating a shearing gap with a fixed blade. A motor drives the shaft's high-speed rotation, tearing, shearing, and crushing the material. Its compact design makes it suitable for both coarse and medium shredding of a variety of materials, including plastics, rubber, paper, wood, and food waste. Its simple single-shaft design ensures stable operation and low energy consumption. Its flexible blade design allows for adaptability to materials of varying hardness and shape, making it widely used in environmental protection, recycling, and manufacturing, helping to reduce solid waste volume and promote resource reuse.

Identify material characteristics: Determine the blade material and gap based on the material's hardness (such as hard plastic/soft rubber), shape (blocky/thin film), and moisture content. For high-humidity materials, select an anti-clogging design.

Match production capacity requirements: Select the cutter shaft diameter and speed according to the hourly processing volume. A small cutter shaft can be selected for a production capacity of 1-5 tons/hour, while a high-power motor and large cutter shaft are required for a production capacity of more than 10 tons.

Consider the blade configuration: choose a large-sized claw knife for shredding coarse materials, a small-sized tooth knife for fine shredding, and a high-hardness alloy blade for easily abrasive materials to ensure easy replacement.

Pay attention to the drive system: For high-frequency operation scenarios, choose a variable frequency motor, which can adjust the speed to adapt to different materials; heavy-load environments require a reduction gearbox and overload protection device.

Check the body structure: For small equipment, choose a compact body to save space. For large equipment, you need to confirm the frame's load-bearing capacity and stability. For outdoor use, choose rainproof and rust-proof materials.

Evaluate follow-up services: Give priority to brands that provide after-sales support such as blade replacement and fault repair to ensure timely supply of wearing parts and reduce the risk of downtime.

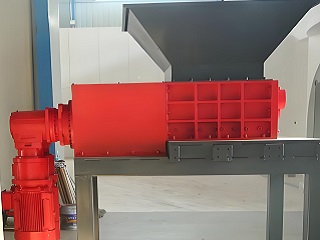

The core shaft of this high-quality single-shaft shredder is forged from a high-strength alloy, and the blades are made from wear-resistant materials, ensuring precise and controllable shear gap. The body is welded from thickened steel, providing a stable and impact-resistant structure. Standardized production of wearing parts ensures strong adaptability, a long lifespan, and easy maintenance. It can withstand heavy loads for extended periods of time, ensuring efficient output.

Single-shaft shredders offer multi-dimensional customization: the blade shaft diameter and length can be adjusted based on production capacity, while the blade material and tooth shape are tailored to the material characteristics. The shredder's dimensions can be customized to suit your site space. Additional accessories such as dust removal and conveying systems can be added to precisely meet the needs of diverse applications, including environmental protection and manufacturing.

The single-shaft shredder offers outstanding performance: precise shearing between the blade shaft and the fixed blade, high shredding efficiency, and the ability to quickly process a wide range of materials. Its drive system is powerful and stable, with low energy consumption. Equipped with overload protection, it operates safely and reliably, with a low failure rate over long periods of operation, making it suitable for diverse working conditions.

The single-shaft shredder features a single blade shaft at its core, offering a compact and simple structure. The blade shaft and fixed blade form a precise shearing gap, making operation and maintenance easy. It offers strong adaptability, stable operation, and low energy consumption. The single-shaft drive design reduces energy loss and provides high shredding efficiency.

The operation of a single-shaft shredder relies on a continuous process of "power drive - material conveying - shearing and crushing - finished product discharge." This process revolves around the coordinated operation of the single cutter shaft and its associated components. Its working principle can be broken down into the following key steps.

1. Power Transmission System Startup

After the machine is started, the motor, acting as the power source, begins to rotate, transmitting power to the reduction gearbox via a coupling. The reduction gearbox converts the motor's high-speed rotation into the low-speed, high-torque output required by the cutter shaft, ensuring sufficient shear force during the crushing process. Some high-end models are equipped with a variable frequency control system that adjusts the motor speed in real time according to material hardness, enabling precise adaptation of power output. Simultaneously, an overload protection device is activated to immediately cut off power if an anomaly such as material jamming occurs in the subsequent crushing process, preventing damage to the equipment.

2. Material Conveying and Induction

Material to be crushed enters the machine via a conveyor belt, feed hopper, and other devices. The feed inlet is typically designed with an inclined or forced feed mechanism. Small materials can slide down by their own weight, while large or sticky materials are pushed by a pusher, ensuring stable entry into the crushing zone. Some equipment incorporates a pre-treatment device at the feed inlet to initially shape the material and prevent feed blockage caused by material accumulation.

3. Core Shearing and Crushing Process

This is the key operating step in a single-shaft shredder. Multiple sets of staggered moving blades are evenly arranged on the blade shaft, creating a small shear gap with the fixed blades fixed to the inner wall of the shredder. When material enters the gap between the moving and fixed blades, the high-speed rotation of the moving blades, coupled with the high torque transmitted by the reduction gearbox, creates tearing, shearing, and squeezing forces on the material.

The crushing mechanisms vary slightly depending on the material: For flexible materials like plastic and rubber, the staggered shearing of the moving and fixed blades quickly rips them into small pieces; for hard materials like wood and hard plastics, a combination of squeezing and shearing is used to crush them. The blade tooth profile, material, and shear gap can be adjusted according to the material's characteristics to ensure precise and controllable crushing results.

4. Product Screening and Discharge

The shredded material is screened. Finished products that meet the required particle size fall through the gaps in the screen onto the discharge conveyor below and are transported to a designated collection device. Materials that do not meet the particle size standard remain in the crushing area, undergoing further shearing by the rotating and fixed blades until they meet the required particle size and are discharged. The screen aperture can be changed as needed, flexibly controlling the finished product particle size and adapting to different subsequent processing requirements.

Throughout the entire operation, all systems work together to form a closed loop from power supply to finished product discharge. This ensures both efficient crushing and precise material processing, and is the core technology behind the widespread application of single-shaft shredders in solid waste management.

| Model | Feed Opening Size | Power | Speed | Capacity | Blade Material | Weight | Dimensions |

|---|---|---|---|---|---|---|---|

| SHRED-1000 | 500 x 500 mm | 15 kW | 30 RPM | 500-1000 kg/h | Alloy Steel | 1200 kg | 2000 x 1200 x 2200 mm |

| SHRED-1500 | 600 x 600 mm | 18 kW | 25 RPM | 1000-1500 kg/h | Alloy Steel | 1500 kg | 2200 x 1300 x 2400 mm |

| SHRED-2000 | 800 x 800 mm | 22 kW | 20 RPM | 1500-2000 kg/h | High Strength Steel | 1800 kg | 2500 x 1400 x 2500 mm |

| SHRED-2500 | 1000 x 1000 mm | 30 kW | 18 RPM | 2000-2500 kg/h | Tungsten Steel Alloy | 2000 kg | 2800 x 1600 x 2700 mm |

| SHRED-3000 | 1200 x 1200 mm | 37 kW | 15 RPM | 2500-3000 kg/h | Tungsten Steel Alloy | 2500 kg | 3000 x 1700 x 3000 mm |

| SHRED-4000 | 1500 x 1500 mm | 45 kW | 12 RPM | 3000-4000 kg/h | High Hardness Steel | 3000 kg | 3500 x 2000 x 3200 mm |

*The output will vary according to different materials, feed particle size and other factors.

Save Time! Get A Detailed Quotation Quickly.