The flip flow screen is a high-efficiency screening equipment. Its core is a combination of an elastic screen surface and a rigid screen frame. The reciprocating motion of the two causes the screen surface to alternately relax and relax, which can effectively handle wet and sticky materials and avoid blockage. It is mostly used for grading coarse and medium-grained materials such as coal and ore, with high screening efficiency and strong adaptability.

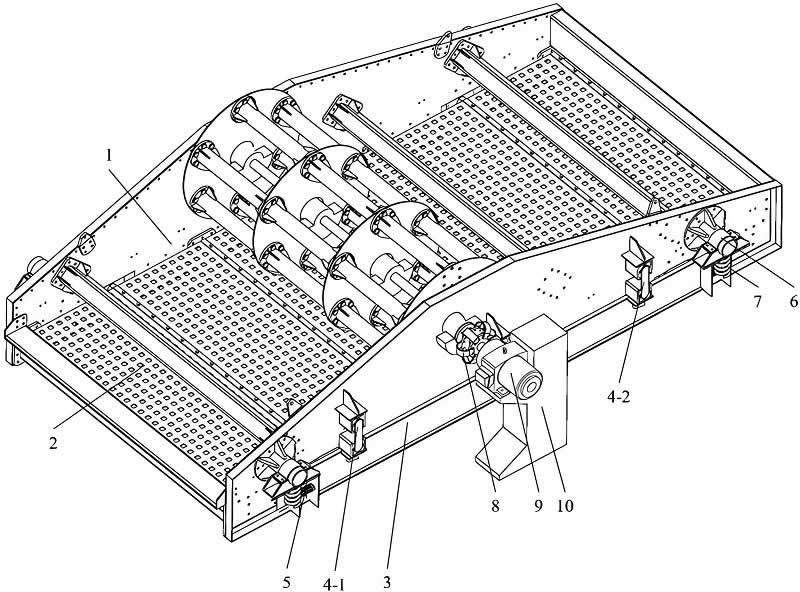

The flip flow screen is a highly efficient grading device designed specifically to address the challenges of screening wet and sticky materials. Its unique structure and operating mode have made it widely used in the processing of coarse and medium-grained materials. Its core structure consists of an elastic screen surface (mostly made of polyurethane) and a rigid screen frame. Driven by an eccentric shaft or an exciter, the rigid screen frame undergoes reciprocating motion, driving the elastic screen surface alternately between relaxation and tension, generating high-frequency, small-amplitude elastic vibrations.

This motion produces a strong "self-cleaning" effect: when the screen surface is relaxed, relative sliding occurs between the material and the screen surface, effectively removing adhered material. When tensioned, it enhances the force required for material to pass through the screen, completely eliminating the clogging problem encountered by traditional screening equipment when handling wet and sticky materials. Screening efficiency can reach over 85%, significantly exceeding that of conventional vibrating screens.

This device is primarily suitable for coarse and medium-grained materials (typically 5-300mm in size), such as coal, ore, and construction waste. It is particularly suitable for handling materials with high moisture content and high viscosity, such as wet coal and clay ore. At the same time, its elastic screen surface is wear-resistant and impact-resistant, has a long service life, and the equipment operates with low noise. The vibration parameters and screen surface diameter can also be adjusted according to the material characteristics. It has strong adaptability and is a key equipment for material grading in mining, coal, building materials and other industries.

1.Choose based on the characteristics of the material being processed: Prioritize the material's particle size (whether it's within the 5-300mm coarse-medium range), moisture content, and viscosity. Select a model that's compatible with the screen surface diameter and elastic screen material to avoid inefficient screening or clogging due to material mismatch.

2.Focus on the core structure and drive system: Verify that the elastic screen surface is made of wear-resistant polyurethane to ensure longevity. Confirm the operational stability of the drive unit (eccentric shaft or exciter). Select a model that offers high-frequency, low-amplitude vibration to ensure "self-cleaning."

3.Consider the application scenario and production capacity requirements: For coal and mining applications, select a heavy-duty model that's impact-resistant and wear-resistant. For construction waste processing, consider the equipment's compatibility with mixed materials and ensure that the equipment's processing capacity is slightly higher than its actual capacity to meet continuous operation requirements.

4.Focus on screening efficiency and parameter adjustability: Prioritize models with screening efficiencies exceeding 85%. Verify whether parameters such as vibration frequency and amplitude can be adjusted based on material variations to accommodate the screening needs of materials with varying moisture contents and viscosity, ensuring consistent separation results.

5.Verify equipment durability and auxiliary configurations: Inspect the structural strength of the rigid screen frame and confirm whether anti-clogging devices are installed. Pay attention to operating noise levels and select models with low noise and easy maintenance. Also, understand the replacement cost and cycle for wearing parts (such as the screen surface).

6.Reflect on manufacturer strength and after-sales support: Select manufacturers with proven application cases in similar industries (such as coal and building materials). Verify whether they offer on-site testing, installation and commissioning, and operator training. Inquire about after-sales response speed and maintenance support to mitigate risks associated with future equipment use.

It uses wear-resistant polyurethane screen surface and high-strength rigid screen frame, with a stable and durable structure; the drive system is precise and the vibration parameters are stable; the process meets industry standards, with long-lasting anti-blocking effect, few operating failures, easy maintenance, and the ability to efficiently process high-humidity and high-viscosity materials over a long period of time.

It supports multi-dimensional customization, and the screen surface diameter and polyurethane screen surface hardness can be customized according to the material particle size and viscosity; the equipment size can be adjusted according to production capacity requirements; and anti-blocking devices and dust removal systems can be added to adapt to different scenarios such as coal and mining to meet personalized screening needs.

The high-frequency relaxation motion allows the screening efficiency of high-humidity and high-viscosity materials to reach over 85%, and the anti-blocking effect is long-lasting; the vibration parameters are stable and adaptable to materials of various particle sizes; the operation is low in noise, energy consumption is low, the continuous operation failure rate is low, and the high-efficiency screening state can be maintained for a long time.

The combined design of elastic screen surface and rigid screen frame and high-frequency relaxation movement can prevent wet and sticky materials from clogging and achieve high screening efficiency. The screen surface is wear-resistant and durable, suitable for coarse and medium-grained materials. The vibration parameters can be adjusted to adapt to multiple scenarios. It also has low operating noise and is easy to maintain, making it suitable for processing high-humidity and high-viscosity materials.

The operating principle of a flap screen revolves around the dynamic linkage of an elastic screen surface and a rigid screen frame. Its core goal is to achieve efficient screening of wet, sticky materials through specialized motion. The specific process can be divided into three steps:

First, the power drive and structural linkage. An eccentric shaft or vibrator provides power, driving the rigid screen frame in reciprocating linear motion. The rigid screen frame is flexibly connected to the elastic screen surface (mostly made of polyurethane). As the screen frame moves, it pulls on the elastic screen surface, causing it to alternate between "tensioned" and "relaxed" states, generating high-frequency, small-amplitude elastic vibrations.

Second, it provides material screening and prevents clogging. The material to be processed (mostly coarse and medium-grained wet, sticky materials, 5-300mm in size) is evenly deposited onto the screen surface through the feed mechanism. The flap screen motion generates a strong bouncing and kneading force, pushing the material forward along the screen surface while dislodging any material adhering to the screen mesh, completely eliminating the clogging problem of traditional screens. Simultaneously, material that meets the required particle size passes through the screen during vibration and enters the next process, while material that exceeds the required size is discharged from the end of the screen surface. Finally, parameter adaptation and performance optimization are key. By adjusting the drive parameters, the equipment can change the screen surface relaxation frequency and amplitude to adapt to materials with varying moisture content and viscosity (such as wet coal and clay ore). This ensures a screening efficiency of over 85% even in high-humidity environments, achieving stable and efficient material classification.

| No. | Model | Screen Size (mm) | Screen Area (m²) | Layers | Capacity (t/h) | Vibration Frequency (Hz) | Motor Power (kW) | Dimensions (mm) | Weight (kg) | Application Material |

|---|---|---|---|---|---|---|---|---|---|---|

| 1 | CZ-1230 | 1200 × 3000 | 3.6 | 1 | 10–25 | 4–6 | 7.5 | 3500 × 1800 × 1800 | 1800 | Sand, coal powder, mineral particles |

| 2 | CZ-1530 | 1500 × 3000 | 4.5 | 1 | 15–30 | 4–6 | 11 | 3700 × 2000 × 1900 | 2200 | Construction sand, gangue, quartz sand |

| 3 | CZ-1836 | 1800 × 3600 | 6.5 | 1 | 25–45 | 4–6 | 15 | 4200 × 2200 × 2000 | 2800 | Limestone, river pebbles, ore powder |

| 4 | CZ-1845 | 1800 × 4500 | 8.1 | 1 | 35–60 | 4–6 | 18.5 | 5000 × 2300 × 2100 | 3200 | Fly ash, manufactured sand, ceramsite |

| 5 | CZ-2045 | 2000 × 4500 | 9.0 | 1 | 45–70 | 4–6 | 22 | 5200 × 2500 × 2200 | 3800 | Ore, coal, construction aggregates |

| 6 | CZ-2460 | 2400 × 6000 | 14.4 | 1 | 60–100 | 4–6 | 30 | 6800 × 2800 × 2300 | 5200 | High-moisture sticky materials, gravel |

| 7 | CZ-3060 | 3000 × 6000 | 18.0 | 1 | 80–120 | 4–6 | 37 | 7000 × 3200 × 2400 | 6500 | Large-size ore, coal classification |

*The output will vary according to different materials, feed particle size and other factors.

Save Time! Get A Detailed Quotation Quickly.