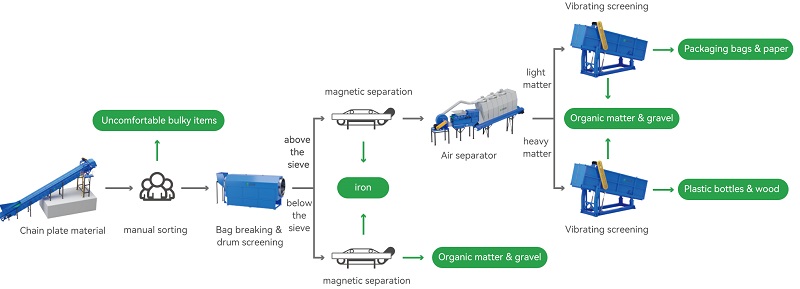

1. Refined Sorting: Multi-stage screening, magnetic separation, and air separation achieve efficient separation of metals, plastics, and organic matter.

2. High Resource Utilization: Recyclables are recycled, and organic waste is used to generate biogas or compost, reducing landfill waste.

3. Strong Environmental Performance: Dust removal, leachate treatment, and odor control are integrated to reduce secondary pollution.

4. Energy Recovery: Anaerobic digestion generates biogas for power generation, promoting green energy applications.

5. High Level of Automation: Intelligent equipment and information management are introduced to improve operational efficiency.

6. High Policy Compliance: Complies with national and Beijing municipal waste sorting and green development requirements, contributing to sustainable urban development.

| Equipment | Main Function | Key Features |

|---|---|---|

| Vibrating / Drum Screen | Initial classification by particle size | High throughput, suitable for continuous large-scale operations |

| Magnetic Separator | Separate and recover ferrous metals | Efficient metal recovery, reduces secondary pollution |

| Eddy Current Separator | Sort non-ferrous metals (aluminum, copper) | Improves recycling rate, supports metal reuse |

| Air Separator | Distinguish light (plastic, paper) and heavy materials | Energy efficient, high sorting accuracy |

| Crusher | Reduce bulky waste size for further processing | Handles various materials, lowers transport difficulty |

| Conveyor System | Transport materials between processing units | Stable operation, high automation |

| Washing / Cleaning System | Remove soil and impurities from recyclables | Improves quality of recovered materials |

| Dust & Wastewater Treatment Units | Control dust, leachate, and wastewater | Ensure environmental compliance, reduce secondary pollution |

Save Time! Get A Detailed Quotation Quickly.