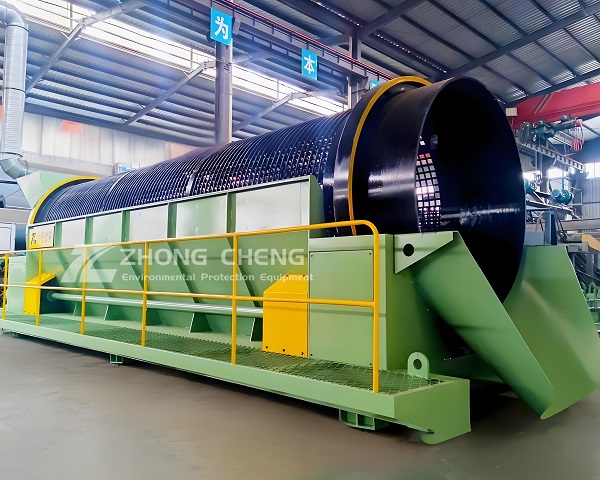

In the context of the rapid development of industries such as mining, sand and gravel, chemical engineering, metallurgy, environmental protection, and renewable resources, the performance and reliability of screening equipment directly determine the efficiency and cost of enterprise production lines. Among these, trommel screens have become the preferred choice for many companies due to their simple structure, strong adaptability, and low failure rate. Among the numerous trommel screen manufacturers, Zhongcheng Machinery has won widespread recognition for its exquisite manufacturing process, rich industry experience, and stable product quality. So, why are more and more users choosing Zhongcheng Machinery's trommel screens? This article systematically explains this from multiple dimensions, including technical advantages, manufacturing strength, application performance, after-sales service, and cost-effectiveness.

A. Optimized Structural Design, Stable and Reliable Operation

The core performance of a trommel screen comes from its structural design and manufacturing precision. Based on years of practical experience, Zhongcheng Machinery has systematically optimized the cylinder structure, support system, transmission method, and sealing system of the trommel screen, making the equipment exceptionally stable in actual operation.

1. High Cylinder Strength and Long Service Life

The cylinder is made of high-strength carbon steel material, processed through CNC plate rolling, automatic welding, and overall annealing treatment, possessing good rigidity and toughness, and is not easily deformed. It can maintain stability even under long-term full-load operation.

2. Reasonable Support Structure

Zhongcheng Machinery adopts a multi-point support structure and determines the optimal contact position through mechanical analysis, ensuring uniform force distribution on the cylinder, reducing bearing pressure, and extending its lifespan.

3. Smooth Transmission and Low Noise

The equipment can be configured with gear, chain, or direct-drive transmission via a reducer, with the appropriate method selected for different working conditions. The transmission system is dynamically balanced, resulting in low operating noise and improved energy efficiency.

4. Advanced Anti-Clogging Design

Screen hole clogging has always been a pain point for many trommel screens. Zhongcheng Machinery's equipment adopts designs such as staggered screen holes and cleaning systems (such as bouncing balls and cleaning brushes) to effectively reduce clogging and ensure screening efficiency.

B. High Screening Efficiency and Strong Adaptability

Zhongcheng Machinery's trommel screens are suitable for a variety of material types, from granular materials, wet materials, and mixed materials to complex raw materials containing many impurities, and their screening effect is excellent. 1. Multi-stage Screening Structure

1.The screening system can be designed with one, two, or even multiple stages according to customer needs, achieving the separation of different particle sizes. The screen drum adopts an involute design, resulting in more uniform material distribution within the drum and an increase in screening efficiency of approximately 20% to 30%.

2. Strong Adaptability to Wet and Viscous Materials

Compared to vibrating screens, rotary screens are less affected by humidity and viscous materials. Zhongcheng Machinery enhances its efficiency in screening wet sand, wet soil, and fermented organic fertilizers by adding features such as increased inclination and cleaning devices.

3. No Clogging, No Blind Holes

The screen mesh uses various options such as wear-resistant manganese steel mesh, perforated plates, and polyurethane mesh, which can be customized according to the customer's material characteristics to avoid efficiency reduction caused by material clogging.

4. Suitable for Multiple Industries and Working Conditions

Zhongcheng Machinery's rotary screens are widely used in:

Construction waste treatment

Sand and gravel aggregate screening

Soil remediation and classification

Organic fertilizer and compound fertilizer production

Wood chips, coal, and ore screening

Urban waste and resource recycling

Its strong adaptability ensures that users can meet multiple production needs with a single piece of equipment.

C. Advanced Manufacturing Process, More Controllable Quality

Zhongcheng Machinery has a complete production system and a strict quality management system. From raw materials to assembly and debugging, the entire process is strictly controlled by a professional team.

1. CNC Production Process

Plate rolling, cutting, punching, and welding all utilize automated and CNC equipment, improving structural accuracy, reducing human error, and extending the overall service life of the equipment.

2. Stable Welding Quality

All drum welds undergo non-destructive testing (such as ultrasonic and penetration testing) to ensure quality and avoid potential cracks during long-term operation.

3. Whole Machine Dynamic Balancing Test

The drum undergoes dynamic balancing calibration before leaving the factory, resulting in smoother operation and reduced vibration and noise.

4. Strict Testing System

Each piece of equipment must undergo at least 2 hours of no-load testing and load simulation testing before shipment to ensure it meets the required standards. D. Low Energy Consumption, Simple Maintenance, and Lower Operating Costs

D.One of the advantages of the trommel screen is its low energy consumption, and Zhongcheng Machinery further reduces energy consumption by optimizing the transmission structure and reducing friction.

1. Significant Energy Saving and Consumption Reduction

Compared with vibrating screens of the same capacity, it saves about 20% of energy. The equipment adopts a friction-reducing design internally, resulting in smoother rotation and lower power consumption.

2. Fewer Wear Parts and Low Maintenance Costs

The overall structure of the trommel screen is simple, and the main components such as bearings and reducers are selected from well-known domestic and foreign brands, resulting in an extremely low failure rate.

3. Convenient Maintenance

The screen drum is detachable and replaceable; the screen mesh adopts a modular design, shortening replacement time and reducing downtime losses. Equipment maintenance personnel do not require high professional skills to complete daily maintenance.

4. Long Service Life and Low Overall Cost

The excellent structural design and material standards ensure that the equipment generally has a service life of 5-10 years or more, and the overall operating cost is far lower than similar products.

E. Customizable According to Working Conditions, Truly Meeting Enterprise Needs

Zhongcheng Machinery provides a one-stop service from scheme design to equipment customization, truly achieving "tailor-made".

1. Multiple Specifications Available

Diameters from 0.6m to 3.0m and lengths from 3m to 12m can be freely combined to meet different production capacity requirements.

2. Customized Screen Structure According to Materials

Flexible combination of metal mesh, polyurethane screen plates, perforated mesh, bar screens, etc.

3. Customized Inlet and Outlet Directions According to Site Layout

Left-in right-out, right-in left-out, high-position feeding, low-position discharge, etc., can all be customized.

4. Auxiliary Systems Can Be Added

Including spray cleaning, sealed dust removal, automatic lubrication, variable frequency speed regulation, etc., to fully adapt to complex working conditions.

E. Comprehensive After-Sales Service System, Giving Users Peace of Mind

Zhongcheng Machinery not only provides products but also focuses on service experience. Professional teams are responsible for pre-sales, in-sales, and after-sales services.

1. Pre-sales Technical Support

Engineers can visit the customer's site to inspect materials and production lines and provide scientific screening solutions.

2. Fast and Stable Delivery

Regular models are kept in stock and can be shipped in a short time; the production cycle of customized models is clear and transparent. 3. Professional Installation and Commissioning

We provide on-site installation guidance or complete installation services to ensure rapid equipment commissioning.

4. Long-term After-sales Support

We provide a full range of services including equipment maintenance, technical upgrades, and spare parts supply, ensuring lifelong maintainability of the equipment.

F. Significant Cost-Effectiveness Advantages

While offering superior performance, long lifespan, and stable operation, Zhongcheng Machinery's trommel screens are reasonably priced, offering exceptional value for money.

1. Reasonable equipment price

2. Long service life and low failure rate

3. Low cost and stable supply of spare parts

4. Strong energy-saving capabilities, reducing long-term electricity costs

Therefore, the overall cost is more economical than similar products. Choosing Zhongcheng Machinery means choosing stability, efficiency, and reliability.

Zhongcheng Machinery's trommel screens are favored by more and more enterprises due to their reliable structure, high screening efficiency, strong adaptability, exquisite manufacturing process, low maintenance costs, comprehensive service, and high cost-effectiveness. Whether it's sand and gravel classification, waste treatment, soil screening, organic fertilizer production, or other complex working conditions, Zhongcheng Machinery can provide practical solutions to help enterprises reduce costs and improve efficiency.

If you are looking for a trommel screen that can withstand the test of time and truly improve productivity, Zhongcheng Machinery is undoubtedly a trustworthy choice.

Save Time! Get A Detailed Quotation Quickly.