Wind Sifter are separation devices based on the principles of airflow dynamics. They use fans to generate controlled airflow, separating materials based on density and particle size. They offer high separation efficiency, low energy consumption, and ease of operation, making them crucial equipment for material purification and resource recovery in industrial production.

Wind sifter are a type of material separation equipment designed based on the principles of airflow dynamics. Their core operating principle is to generate a controlled airflow, leveraging the inherent differences in density, particle size, and shape of different materials to achieve impurity removal, particle size classification, or efficient separation of heavy and light materials. As a highly versatile separation device, they are widely used in a variety of fields, including agricultural production, industrial processing, and environmental recycling, providing technical support for material purification and resource optimization in various scenarios.

Based on their application scenarios, wind sifter can be broadly divided into four categories: Household and agricultural models are primarily used to clean granular materials such as grain and seeds, ensuring the quality of basic agricultural products; models for the food and light industry sectors are suitable for handling materials such as fruits, vegetables, and plastics, connecting to pre-processing stages of production lines; models for the ore and heavy industry sectors are designed to sort bulk hard materials, facilitating mineral development and construction waste recycling; and fine separation models are targeted at industries with high purity requirements, such as pharmaceuticals and chemicals, processing powdered materials to meet the demands of precision production.

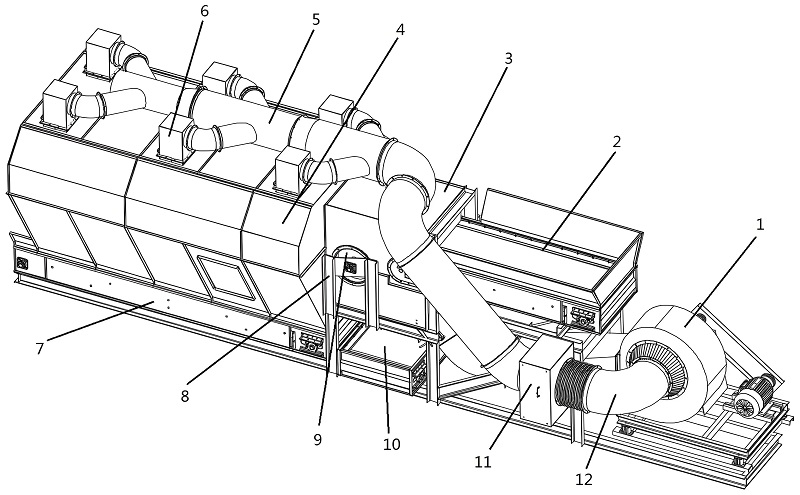

In practical applications, wind sifter typically require pretreatment devices and auxiliary systems to work in conjunction with them. The pretreatment stage can carry out preliminary regularization of the raw materials, and the auxiliary system can optimize airflow control and environmental adaptability. Through such a combination configuration, the sorting efficiency and accuracy of the equipment can be effectively guaranteed, so that it can continue to play an important role in key links such as material purification and resource recycling, and become one of the important equipment to promote green and efficient production in various industries.

1. Prioritize matching material characteristics and clarify core sorting requirements. Based on the properties of the material being processed (granules, mixed materials, powders, etc.), determine the sorting capabilities that require special attention, such as light impurity removal, light-heavy separation, or contamination prevention, and then select a machine model with appropriate features.

2. Determine the machine size and configuration based on the application scenario. Based on the production capacity, space, and material characteristics of the application (home/industrial/environmental), select a machine with the appropriate size and drive method, and compatibility with existing equipment. Pay attention to performance requirements such as wear and corrosion resistance for specific environments.

3. Focus on the airflow control system to ensure sorting accuracy and stability. Prioritize models with variable-speed fans, multi-stage air duct designs, and airflow pressure monitoring to adapt to material variations, improve sorting accuracy, and promptly troubleshoot air duct problems.

4. Verify the equipment's materials and craftsmanship to ensure durability and safety. Select appropriate materials (food-grade, wear-resistant, etc.) based on the material characteristics, and verify that the equipment has safety features such as anti-jamming, explosion-proof, and waterproof features.

5. Evaluate auxiliary systems and after-sales service to reduce ongoing costs. Prioritize models with auxiliary systems such as pre-treatment and dust removal. Also confirm whether the manufacturer provides after-sales support, such as installation training and spare parts supply.

6. Verify the equipment's practicality by referencing actual use cases and word-of-mouth reviews. Choose a manufacturer with industry-leading application cases and trial runs. Also, pay attention to user reviews, such as equipment failure rate, trouble-free uptime, and the manufacturer's after-sales response speed.

High-quality air separators are made of high-quality wear-resistant materials and precise workmanship; the core components are durable, the sorting performance is stable and the accuracy is long-lasting; they are equipped with complete safety protection and are suitable for multiple scenarios.

The wind sifter can be customized as needed, and the machine size and air duct can be adjusted according to the material characteristics and processing volume; dust removal, pre-treatment and other functions can also be added to adapt to different scenarios and meet personalized material sorting needs.

The wind sifter has high sorting efficiency and high precision, and can stably process a variety of materials; it has low energy consumption and few faults during operation, is adaptable to continuous operation in different scenarios, and can maintain good material separation effects after long-term use.

The air separator relies on airflow sorting and is suitable for a variety of materials and scenarios. It has high sorting efficiency and controllable precision. It is easy to operate and can be connected to the production line for continuous operation. The equipment is highly durable, and some models are equipped with environmentally friendly dust removal functions, with low energy consumption, which can reduce material handling costs and assist in resource recovery and purification.

The core operating principle of an wind sifter is to utilize the dynamics of airflow and the differences in the physical properties of materials to separate different materials. The overall process can be divided into four key steps, as follows:

First, the airflow generation step. The equipment uses a fan (the core power component) to generate a controllable airflow. The fan type is adapted according to the needs (e.g., centrifugal fan, axial flow fan). The airflow is then transformed into a stable, directional airflow field through the air duct system. The air speed and pressure can be adjusted through variable frequency speed regulation or dampers to meet different material separation requirements.

Second, the material feeding and airflow contact step occurs. The material to be processed is evenly introduced into the sorting area through a feeding device (such as a conveyor belt or hopper), ensuring that the material is dispersed and fully exposed to the airflow. Some models are equipped with a pre-treatment device (such as a vibrating screen) to remove oversized impurities or break up agglomerated materials to prevent interference with the airflow and material interaction.

Next, the core material separation step occurs. When materials enter the airflow field, the forces acting on them (buoyancy, drag) differ from their own gravity due to their varying density, particle size, and shape. Low-density, fine-particle materials (such as impurities and light objects) experience a greater force from the airflow than from gravity, and are carried away by the airflow to a designated collection device. High-density, coarse-particle qualified materials experience a greater force from the airflow than from gravity, and fall along a predetermined trajectory into the qualified product channel, thus separating the light and heavy, and high-quality and low-quality materials.

Finally, there's the auxiliary and optimization phase. During the separation process, some models are equipped with airflow guides and grading screens to further optimize separation accuracy. Simultaneously, a dust removal system operates simultaneously to collect dust generated during the separation process, minimizing environmental pollution and preventing dust from affecting equipment operation, ultimately achieving efficient and clean material sorting.

| No. | Model | Capacity (kg/h) | Power (kW) | Air Flow (m³/h) | Separation Accuracy (%) | Dimensions (mm) | Weight (kg) | Application |

|---|---|---|---|---|---|---|---|---|

| 1 | FX-300 | 300–500 | 3.0 | 1800 | ≥95 | 1200 × 800 × 1500 | 320 | Grains, tea, small particle separation |

| 2 | FX-500 | 500–800 | 4.5 | 2500 | ≥96 | 1500 × 900 × 1650 | 420 | Plastic pellets, pharmaceuticals, light/heavy material separation |

| 3 | FX-800 | 800–1200 | 5.5 | 3200 | ≥97 | 1700 × 950 × 1750 | 560 | Cereals, seed cleaning, recyclates |

| 4 | FX-1000 | 1000–1500 | 7.5 | 4000 | ≥97 | 1800 × 1000 × 1800 | 680 | Grain processing, chemical powder classification |

| 5 | FX-1500 | 1500–2000 | 11 | 5500 | ≥98 | 2000 × 1200 × 1900 | 820 | Corn, wheat, oilseed crop separation |

| 6 | FX-2000 | 2000–3000 | 15 | 7000 | ≥98 | 2200 × 1300 × 2000 | 980 | Large grain depots, feed mills, plastic recycling lines |

| 7 | FX-3000 | 3000–4000 | 18.5 | 9000 | ≥99 | 2500 × 1500 × 2200 | 1250 | Industrial powder classification, composite material screening |

*The output will vary according to different materials, feed particle size and other factors.

Save Time! Get A Detailed Quotation Quickly.