In the sorting system of garbage resource utilization, the air separator, as the core equipment that uses aerodynamic characteristics to separate light and heavy materials, directly determines the recovery rate and purity of lightweight recyclable materials such as plastics and paper sheets based on its screening efficiency. Currently, as the composition of household waste becomes increasingly complex and the demand for resource utilization continues to increase, air purifiers often face efficiency bottlenecks such as "light materials carrying heavy impurities and heavy materials mixing with light components". Combining with the practice of garbage disposal engineering, improving the screening efficiency of the air separator requires precise efforts from five dimensions: equipment structure optimization, process parameter matching, material pretreatment strengthening, operation control upgrading, and system collaborative design, to achieve deep adaptation between equipment performance and processing requirements.

Targeted optimization of the core structure of the equipment is a fundamental prerequisite for improving wind selection efficiency. The airflow field distribution, separation chamber structure, and nozzle design of the air separator directly affect the separation effect of materials, and customized improvements need to be made according to the characteristics of the processed materials. In terms of airflow generation devices, traditional centrifugal fans have poor stability in outputting airflow, which can easily lead to disordered material separation trajectories. They can be replaced with variable frequency vortex air pumps, which can be used in conjunction with air pressure stabilization tanks to control airflow pressure fluctuations within ± 0.5kPa, ensuring smooth suspension of lightweight materials. For the separation chamber, a "contraction expansion" streamlined chamber design is adopted to replace the traditional rectangular chamber, reduce airflow vortex loss, improve the uniformity of airflow velocity distribution in the chamber by 30%, and avoid the accumulation of lightweight materials in blind spots.

The optimization of the structure and layout of the wind nozzle is particularly crucial. In response to the significant differences in the morphology of lightweight materials in mixed waste, a combination design of "main air nozzle+auxiliary side air nozzle" can be adopted: the main air nozzle adopts a flat slit structure, and the air outlet speed is controlled at 12-18m/s, forming a stable horizontal airflow to lift lightweight materials; The auxiliary side air nozzle is arranged obliquely along the side wall of the separation chamber, with a wind speed adjusted to 8-10m/s, effectively blowing away light impurities attached to the surface of heavy materials. At the same time, the material of the air nozzle will be upgraded to wear-resistant ceramics to avoid deformation caused by material impact and ensure long-term stability of the airflow output direction. In a certain household waste treatment project, after the structural optimization mentioned above, the lightweight material recovery rate of the air separator increased from 78% to 92%.

The precise matching and dynamic adjustment of process parameters are the core means to achieve efficient screening. The screening effect of the air separator depends on the coordinated matching of parameters such as wind speed, air volume, material feeding amount, and feeding uniformity. It is necessary to establish a corresponding relationship between "material characteristics parameter settings". For dry materials with a moisture content below 15%, such as waste paper and hard plastics, a combination of high air velocity (15-18m/s) and low air velocity (1200-1500m ³/h) parameters can be used to ensure rapid separation of materials without excessive disturbance by air flow; For wet and sticky materials with a moisture content of 20% -30%, such as soft plastics mixed with kitchen waste, it is necessary to reduce the wind speed to 10-13m/s and increase the air flow to 1800-2200m ³/h, in order to solve the material bonding problem by enhancing the airflow penetration.

The control of feed parameters is equally important. Adopting frequency conversion speed regulation belt conveyor to control the feeding amount, ensuring that the fluctuation of feeding amount per unit time does not exceed ± 5%, and avoiding the turbulence of separation chamber airflow caused by feeding overload; Install a vibrating feeder at the feed inlet to ensure that the material enters the separation chamber in a uniform thin layer, with a material distribution thickness controlled between 5-8cm to prevent incomplete separation caused by local material accumulation. In addition, real-time collection of wind speed data in different areas of the separation chamber is achieved through an online wind speed monitor, combined with a PLC control system to automatically adjust the fan frequency. When the material composition changes, the parameter response time is controlled within 3 seconds to ensure the continuous and stable screening effect.

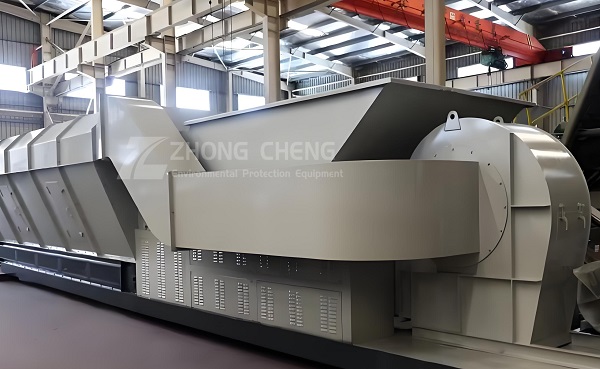

Strengthen the material pretreatment process to clear obstacles for the efficient operation of the air separator. The large impurities, entanglements, and high moisture content materials in mixed garbage are the main causes of the decrease in air separation efficiency, and it is necessary to improve the feed quality through pre-treatment. Install a two-stage pretreatment system in front of the air separator: the first stage uses a shear crusher to crush large garbage with a size greater than 300mm to below 100mm, avoiding it from blocking the airflow channel in the separation chamber; The secondary configuration drum screening machine (such as Zhengzhou Zhongcheng Environmental Protection Customized Drum Screen) separates fine inorganic impurities and high moisture kitchen waste through a 10mm aperture sieve, reducing the adhesion and wrapping of lightweight components by such materials.

For wet and sticky materials, a hot air drying device can be added in the pretreatment stage to reduce the moisture content of the material to below 18% and decrease the adhesion between materials. In a certain decoration waste treatment project, after the three-stage pretreatment of "crushing screening drying", the purity of materials entering the air separator increased by 40%, the purity of light materials in the air separator increased from 65% to 91%, and the frequency of equipment blockage decreased from twice a day to once a week. The improvement of the preprocessing stage not only enhances the efficiency of wind selection, but also extends the service life of equipment and reduces maintenance costs.

Fine control and regular maintenance during operation are long-term measures to ensure stable efficiency. Establish a full process operation and maintenance system of "daily inspection regular maintenance fault warning", check daily whether there is material accumulation at the air outlet of the air nozzle and whether there is dust blockage on the fan filter screen, to ensure smooth airflow delivery; Lubricate and maintain the fan bearings weekly, monitor the airflow pressure and wind speed distribution monthly, and adjust the nozzle angle and fan parameters in a timely manner. In response to the problem of dust accumulation in the wind separator, an automatic pulse dust removal system is equipped to clean the inner wall of the separation chamber with pulse blowing every 30 seconds to prevent dust from adhering and affecting the distribution of the airflow field.

Introducing intelligent monitoring technology to improve the level of control, installing high-definition cameras and material recognition sensors inside the separation chamber to monitor the material separation trajectory in real time, analyzing the separation effect through AI algorithms, and automatically issuing warnings and adjusting wind speed parameters when the proportion of heavy impurities in light materials exceeds 5%; Install a gas flow sensor at the outlet of the fan and establish an energy consumption model based on the feed rate data to achieve "on-demand energy supply" and reduce energy consumption while ensuring screening efficiency. After the intelligent control and renovation of a certain garbage sorting center, the energy consumption per unit processing capacity of the air separator was reduced by 18%, and the effective operating rate of the equipment was increased to 96%.

Build a collaborative system of "wind selection subsequent sorting" to further enhance screening efficiency. The screening efficiency of a wind separator does not exist in isolation and needs to be coordinated with subsequent processes such as magnetic separation, eddy current sorting, and manual sorting. Install a magnetic separation drum at the light material outlet of the air separator to separate mixed iron metals first and avoid damaging subsequent equipment; For lightweight materials after wind selection, secondary fine separation is carried out through an air flow sorting machine, utilizing the density differences of different plastics to achieve the classification and recycling of materials such as PET and PE. At the same time, design the equipment layout reasonably, shorten the material conveying distance between the air separator and subsequent equipment, and reduce the secondary mixing of materials during the conveying process.

In the system design phase, the quantity and combination of air separators need to be determined based on the overall processing scale and material characteristics. For large-scale garbage treatment plants with a daily processing capacity of over 2000 tons, the "multiple parallel+graded air separation" mode is adopted. The front stage air separation machine separates most of the light materials, and the rear stage air separation machine accurately separates the coarse materials. The overall screening efficiency is improved by more than 25% compared to a single air separation machine. By optimizing the design at the system level, complementary functions of various devices can be achieved, maximizing the recovery rate and added value of recyclable materials.

Improving the screening efficiency of wind selection machines is a systematic project that requires breaking through the limitations of "single equipment optimization" and implementing comprehensive measures from five dimensions: structural improvement, parameter regulation, pre-processing enhancement, operation and maintenance upgrade, and system collaboration. In practical applications, personalized optimization plans need to be developed based on the specific characteristics of the processed materials, such as moisture content, composition, particle size, etc., while utilizing intelligent technology to achieve dynamic adjustment and precise control. Through the implementation of the above methods, not only can the screening efficiency and separation accuracy of the air separator be significantly improved, but it can also promote the overall efficiency improvement of the waste resource treatment system, providing solid technical support for the construction of a "waste free city".

Save Time! Get A Detailed Quotation Quickly.