1. Resource Utilization: Through crushing, screening, and sorting, materials such as concrete, masonry, and metal can be reused.

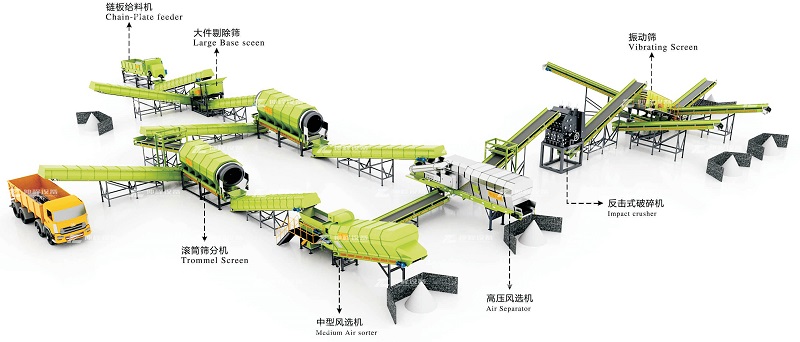

2. Multi-Process Integration: Integrates multiple processing technologies, including crushing, vibrating screens, magnetic separation, and air separation, achieving high processing efficiency.

3. Environmentally Friendly: Equipped with dust removal and wastewater treatment systems, it reduces dust, leachate, and secondary pollution.

4. Wide Adaptability: It can process a variety of construction waste materials, including concrete, bricks, rebar, wood, and plastic.

5. Automation and Continuous Operation: The equipment can be automated to improve production efficiency and stability.

6. Promote the Circular Economy: Recovered renewable materials can be used in road construction, recycled aggregates, and industrial raw materials, supporting sustainable development.

| Equipment | Main Function | Key Features |

|---|---|---|

| Jaw Crusher / Impact Crusher | Crush concrete, bricks, and stones into reusable aggregates | High crushing efficiency, suitable for hard materials |

| Vibrating Screen / Trommel Screen | Classify materials by particle size | Large capacity, continuous operation |

| Magnetic Separator | Recover ferrous metals such as steel and iron | Efficient metal separation, reduces manual sorting |

| Eddy Current Separator | Separate non-ferrous metals (aluminum, copper) | Improves recycling of valuable metals |

| Air Separator | Distinguish light materials (wood, plastics) from heavy ones | Energy efficient, accurate material separation |

| Conveyor System | Transport waste between processing units | Stable operation, fully automated flow |

| Dust & Wastewater Treatment Units | Control dust, leachate, and wastewater emissions | Ensure compliance with environmental standards |

Save Time! Get A Detailed Quotation Quickly.