The tracked mobile screening station is a device that integrates screening and movement functions. It uses tracks to achieve flexible transfer and is suitable for mining, construction and other scenarios. It can handle materials such as sand and gravel, improve material separation efficiency and operational mobility.

The tracked mobile screening station adopts advanced Austrian technology combined with artificial intelligence technology, with high screening efficiency and large output. It is very suitable for operations in complex terrain areas such as narrow sites and urban demolition, especially for construction waste treatment. It can also be used for mineral and hard rock screening, sand and gravel aggregate production, fully meeting customers' mobile screening needs.

The tracked mobile screening station adopts a tracked chassis, which is convenient for transfer and can be applied to various harsh environments.

Compared to traditional fixed screening equipment, this device has stronger mobility and wider adaptability, which can effectively shorten the material processing cycle and help users achieve efficient, environmentally friendly, and flexible production needs. It is one of the core equipment in the field of modern material processing.

1. Clarify material and production capacity requirements: Determine the required screening particle size based on the hardness and humidity of the materials to be processed (sand/ore/construction waste), while matching the actual production capacity to avoid equipment overload or waste of production capacity.

2. Evaluate the walking performance of the track: Priority should be given to equipment with strong track grip and adaptability to complex terrain (mountainous/muddy) to ensure flexible transitions, especially when frequent changes in the work site are required. Walking stability is crucial.

3. Pay attention to the accuracy of the screening system: check the screen material (wear-resistant steel/polyurethane) and vibration frequency adjustment function of the screening machine to ensure that the screening accuracy meets the standard, reduce material mixing, and improve the quality of finished products.

4. Evaluate intelligence and maintainability: Choose an intelligent system with real-time operation monitoring and fault warning, and modular design equipment that can reduce manual operation difficulty, shorten maintenance time, and minimize downtime losses.

5. Compare energy consumption and environmental friendliness: Prioritize low-energy engines and confirm whether the equipment meets dust and noise emission standards to avoid subsequent environmental issues affecting production progress.

6. Consider the manufacturer's after-sales service and reputation: Choose a manufacturer with good industry reputation and wide after-sales network coverage to ensure timely maintenance of equipment in case of malfunctions. At the same time, review user cases to understand the actual stability of equipment use.

The track grip is stable, the screen mesh is wear-resistant, the intelligent monitoring is reliable, and the low consumption meets environmental standards

Customizable screening particle size and processing capacity according to needs, suitable for different materials; Customize track types to adapt to complex terrains; Optional auxiliary equipment is available to meet personalized production needs and enhance operational flexibility.

High screening efficiency, able to quickly separate materials of different particle sizes; The track drive has sufficient power, ensuring stable passage in complex terrains; The body is stable with minimal vibration, low failure rate during continuous operation, and suitable for high-intensity working conditions.

With the advantage of flexible track transfer, it adapts to complex terrain, has high and adjustable screening accuracy, is intelligent and easy to maintain, has low energy consumption and is more environmentally friendly. It can efficiently process multiple types of materials, helping to reduce production costs and improve efficiency.

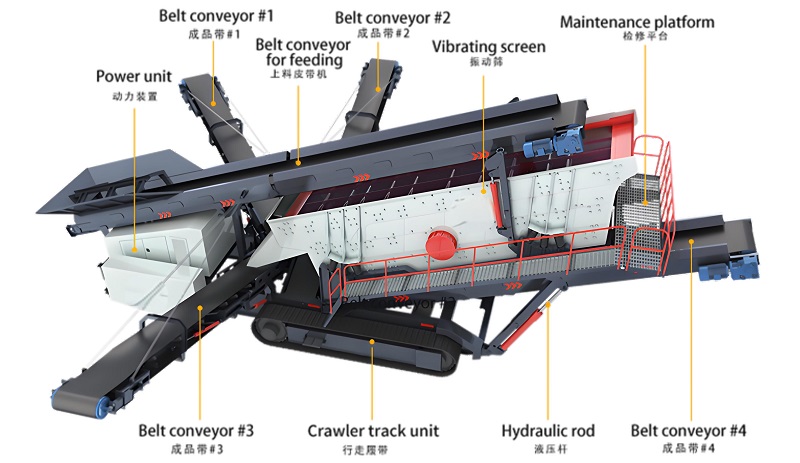

The workflow of the tracked mobile screening station revolves around the four core links of "material conveying grading screening finished product discharge flexible movement", and the various systems work together to achieve efficient material separation.

The first stage is the material conveying stage: the materials to be processed (such as ore, sand and gravel, solid waste, etc.) enter the equipment through the feeding hopper, and are uniformly conveyed to the screening host by the conveyor belt or feeder. At this stage, the feeding speed will be adjusted to avoid material accumulation and ensure continuous and stable screening in the future.

Next, we enter the core screening stage: the screening host is equipped with screens of different apertures (which can be replaced according to needs), and high-frequency vibrations are generated through vibration motors or exciters. The material moves along the sieve surface under the action of vibration, and fine materials smaller than the sieve aperture pass through the sieve to become lower level finished products; Coarse materials larger than the aperture are discharged along the end of the sieve surface and can be returned to the crushing process for secondary processing or directly used as coarse finished products.

Finally, there is the processing of finished products and the movement of the entire machine: finished products of different particle sizes are transported to designated stacking areas through their respective conveyor belts, achieving material classification and collection. At the same time, the track system at the bottom of the equipment can move flexibly within the construction site according to operational needs, without frequent disassembly and assembly, especially suitable for complex outdoor work scenarios such as mining and infrastructure, greatly improving operational mobility and range.

| No. | Model | Screen Layers | Screen Area (m²) | Capacity (t/h) | Feeding Size (mm) | Engine Power (kW) | Travel Speed (km/h) | Dimensions (mm) | Weight (t) | Applicable Materials |

|---|---|---|---|---|---|---|---|---|---|---|

| 1 | YKX-1230T | 2 | 3.6 | 50–150 | ≤150 | 75 | 1.0 | 11500 × 2800 × 3400 | 25 | Construction waste, aggregates |

| 2 | YKX-1540T | 2 | 6.0 | 80–200 | ≤200 | 92 | 1.0 | 12500 × 3000 × 3500 | 29 | Ore, coal, limestone |

| 3 | YKX-1848T | 3 | 8.6 | 100–250 | ≤250 | 110 | 1.0 | 13200 × 3200 × 3600 | 32 | Granite, basalt, river pebbles |

| 4 | YKX-2060T | 3 | 12.0 | 150–350 | ≤300 | 132 | 1.2 | 13800 × 3400 × 3800 | 36 | Quartz sand, manufactured sand, gangue |

| 5 | YKX-2260T | 3 | 13.2 | 180–400 | ≤350 | 160 | 1.2 | 14500 × 3500 × 3900 | 40 | Iron ore, slag, aggregate screening |

| 6 | YKX-2460T | 3 | 14.4 | 200–450 | ≤400 | 185 | 1.3 | 15000 × 3600 × 4000 | 45 | Construction aggregates, recycled concrete |

| 7 | YKX-3060T | 3 | 18.0 | 250–550 | ≤450 | 200 | 1.3 | 15800 × 3800 × 4200 | 50 | Large ores, quarry materials, coal |

*The output will vary according to different materials, feed particle size and other factors.

Save Time! Get A Detailed Quotation Quickly.