With the continuous urbanization of the Philippines, the rapid development of the construction industry has also generated a large amount of construction waste. The disorderly storage and disposal of construction waste not only consumes a large amount of land resources but also poses a significant risk to the environment. Therefore, implementing effective construction waste screening solutions has become a crucial approach to addressing this issue. The core purpose of construction waste screening solutions is to use scientific and technological means to sort, recycle, and reuse construction waste, thereby reducing its negative impact on the environment and promoting resource recycling.

Program Objectives

1. Reduce Environmental Pollution: Through the rational screening of construction waste, we can reduce soil, water, and air pollution.

2. Improve Resource Recovery: We can separate recyclable materials (such as metal, concrete, and bricks) for reuse in construction, road construction, or other industrial applications.

3. Promote Sustainable Development: We will promote green building materials and resource recycling in the construction industry, reducing the consumption of natural resources.

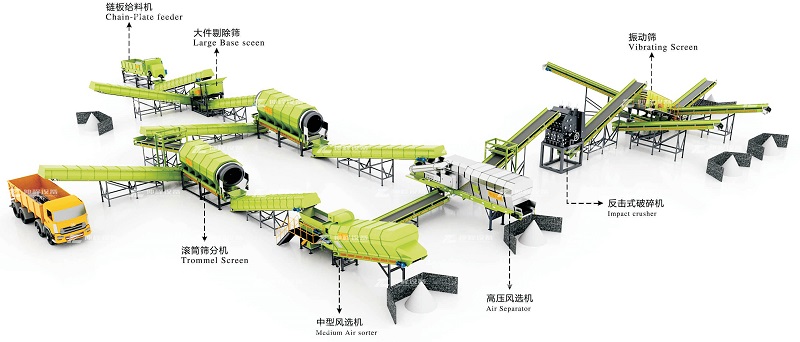

Main Screening Methods and Equipment

1. Vibrating Screens and Drum Screens: These two types of equipment are the most commonly used in construction waste screening. Vibrating screens are primarily used to separate smaller particles, while drum screens are suitable for handling larger, mixed construction waste.

2. Magnetic separation equipment: Used to separate metal materials such as rebar and iron bars from construction waste. These metal materials can be further recycled and reused.

3. Wind sorting technology: Based on density differences, wind power separates lightweight materials (such as plastics and wood) from heavier materials, ensuring a more refined classification.

4. Water washing equipment: Removes impurities such as dirt and dust from construction waste, improving the quality of recyclable materials.

Environmental Protection and Energy Saving

The Philippines places particular emphasis on environmental protection and energy conservation measures when implementing construction waste screening programs. By installing efficient pollution control facilities (such as water treatment systems and air purification units) and using energy-saving equipment, energy consumption and emissions during the screening process are minimized. Furthermore, recovered construction waste, such as crushed concrete and bricks, can be reused in road construction, fill materials, and other applications, thus achieving resource recycling.

The Philippines' construction waste screening solution not only provides a strong guarantee for environmental protection, but also promotes the efficient use of resources and promotes sustainable development. Through comprehensive technical means and strict regulatory support, the treatment and recycling of construction waste will greatly improve the ecological environment in the Philippines and promote the development of the green building industry.

| Equipment Name | Primary Function | Typical Specifications | Applicable Scope |

|---|---|---|---|

| Vibrating Screen | Size grading of concrete, bricks, sand and other particles. | Screen opening: 5–80 mm; Capacity: 30–200 t/h; Power: 7.5–30 kW | Coarse/fine material separation |

| Drum (Trommel) Screen | Initial separation of large-volume, mixed construction waste. | Drum diameter: 1.2–2.5 m; Length: 3–8 m; Capacity: 20–150 t/h | Pre-treatment, coarse screening |

| Magnetic Separator | Recover ferrous metals such as rebar and iron pieces. | Magnetic field strength: 800–1600 Gauss; Belt width: 500–1200 mm; Capacity: 10–100 t/h | Metal recovery |

| Air (Wind) Separator | Separate light materials (wood, plastics) from heavier fractions by density. | Air velocity: 6–12 m/s; Capacity: 5–50 t/h | Light material separation |

| Crusher | Crush concrete blocks and masonry into re-usable aggregates. | Feed size: ≤500 mm; Output size: 10–50 mm; Capacity: 50–300 t/h | Recycled aggregate production |

| Washing System | Wash sand/aggregates to remove soil and impurities, improving recycled material quality. | Water flow: 30–200 m³/h; Screen opening: 1–5 mm | Quality improvement of recycled materials |

| Dust Collector | Control dust emissions from screening and crushing processes. | Airflow: 3,000–20,000 m³/h; Filtration efficiency: >99% | Environmental protection / emission control |

The main features of the Philippines' construction waste screening solution include:

1. Refined Sorting: Utilizing a variety of processes, including vibrating screens, drum screens, magnetic separation, and wind power separation, it can precisely separate a variety of materials, including concrete, bricks, wood, metal, and plastic.

2. Resource Utilization: After screening, concrete fragments can be recycled into recycled aggregate for road and foundation construction; metals can be recycled and reused, reducing the consumption of primary resources.

3. Environmentally Friendly: Supported by dust removal and wastewater treatment facilities, dust, noise, and wastewater emissions are effectively reduced, minimizing secondary environmental pollution.

4. Energy-Saving and High-Efficiency: The introduction of energy-saving screening equipment and automated control systems improves processing efficiency, reducing energy consumption and labor costs.

5. Policy Support: Complying with regulations such as the Philippines' Solid Waste Management Act, it promotes the green transformation and sustainable development of the construction industry.

Save Time! Get A Detailed Quotation Quickly.