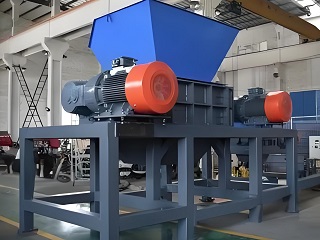

A four-shaft shredder is a highly efficient waste processing device that utilizes four independently rotating blades to shred materials multiple times. Compared to a two-shaft shredder, a four-shaft shredder offers higher processing capacity and more uniform material shredding. It is suitable for processing a variety of hard and tough materials, such as plastic waste, electronic waste, metal, and wood.

A four-shaft shredder is a highly efficient material shredder that utilizes four independently rotating blades to break materials into uniform, small pieces through multiple cutting and tearing actions. Its design principle, based on a low-speed, high-torque rotational method, effectively reduces fine material fragmentation and is suitable for processing a variety of difficult-to-shred waste materials, such as waste plastics, rubber, metal, wood, and electronic waste.

Compared to traditional two-shaft shredders, the four-shaft shredder utilizes four blades to achieve more efficient, multiple shredding operations in a shorter timeframe, ensuring more uniform material processing. It is suitable for processing large, hard materials. The blades of the four-shaft shredder are made of highly wear-resistant material, offering a long service life and strong crushing force, making it suitable for shredding a variety of complex waste materials.

The four-shaft shredder features a compact design, easy operation, low noise levels, and low energy consumption. Its low-speed operation effectively reduces wear and malfunctions, extending the machine's service life. Safety features such as overload protection and emergency stop ensure the safety of both personnel and equipment during production.

Four-axis shredders are widely used in waste recycling, resource reuse, environmental protection and other fields. They are important equipment for modern waste treatment and resource recycling, which can improve resource utilization efficiency and reduce environmental pollution.

When choosing a four-axis shredder, first determine the material type you're processing. Different materials (such as plastic, metal, wood, rubber, etc.) have different requirements for the machine. Ensure the machine's blade material, feed port size, and processing capacity are suitable for the target material. Especially for hard and tough materials, choose a machine with more wear-resistant blades and lower speeds to maximize processing efficiency and service life.

Processing capacity and power. Choose the appropriate processing capacity and power specifications based on production needs. The power of a four-axis shredder directly affects its processing capacity and efficiency. Ensure the power of the selected equipment can support daily production loads while avoiding excessive power that wastes energy. The equipment's processing capacity should meet the needs of the production line to avoid production bottlenecks caused by insufficient processing capacity.

Blade material and durability. The blade material of a four-shaft shredder is a key factor affecting its performance and lifespan. High-quality blade materials, such as alloy steel or high-strength steel, can effectively improve shredding efficiency and extend blade life. When purchasing, check the blade's wear resistance and corrosion resistance to ensure that the equipment can maintain efficient and stable operation under high loads.

Safety and ease of operation. Safety is a key consideration when selecting a four-axis shredder. The equipment should include safety features such as overload protection, emergency stop, and automatic lubrication to prevent accidents caused by operator error or mechanical failure. Furthermore, the operating system should be simple and easy to understand, allowing for quick learning and reducing training time to prevent equipment damage or production downtime due to improper operation.

Maintenance and servicing ease. Consider the ease of routine maintenance and upkeep when purchasing. High-quality four-shaft shredders typically feature easy blade replacement and cleaning, reducing downtime and repair costs. Check the equipment's maintenance requirements and replacement cycles for wearing parts to ensure that future maintenance isn't overly complex or expensive.

After-sales service and brand reputation. Choosing a four-shaft shredder from a reputable brand generally guarantees quality and reliability. Be aware of the manufacturer's after-sales service offering, including installation and commissioning, technical support, parts availability, and repair services. Reputable manufacturers typically offer comprehensive after-sales guarantees, ensuring timely maintenance and technical support during equipment use, reducing the risk of downtime.

Strong and durable structure and high efficiency. The use of high-strength steel and wear-resistant blades ensures that the equipment maintains excellent crushing performance during long-term operation.

It is highly customizable and offers a variety of configuration options based on customer needs. Customization includes feed size, blade type, processing capacity, power level, etc. to meet the processing requirements of different materials.

Powerful processing capacity and efficient crushing effect. The four-axis design ensures that the material is crushed quickly and evenly through multiple cutting and tearing actions.

It can handle a wide range of hard, tough waste materials, such as plastics, metals, rubber, and wood. Its four-axis design uses multiple cutting and tearing actions to ensure uniform material crushing and high efficiency. Low-speed, high-torque operation reduces energy consumption and noise, extending the life of the equipment.

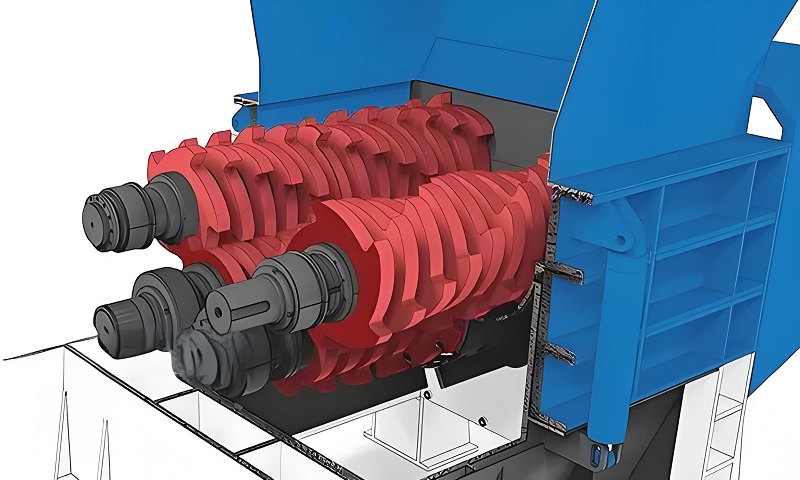

The four-shaft shredder's operating principle is based on its unique four-shaft design. Four independently rotating blades tear, shear, and compress the material multiple times, achieving efficient shredding. Unlike traditional dual-shaft or single-shaft shredders, the four-shaft shredder features not only a large number of blades but also a uniform distribution of blades, enabling more efficient and uniform shredding.

In operation, material enters the machine through the feed inlet, where four rotating blades, using precision-designed blades, grab and tear the material. The blades of each blade rotate in an interlaced pattern, creating multiple cutting actions. This high-frequency shredding process effectively reduces particle size. Due to its low-speed, high-torque operation, the four-shaft shredder maintains low energy consumption and reduces wear on the machine when processing tough and resilient materials.

The four blades work together to evenly distribute shear force on the material, resulting in multiple, quick cuts into smaller pieces. This design not only improves shredding efficiency but also prevents excessive fragmentation, ensuring a more uniform size of shredded material, making it easier to recycle and reuse.

The blades of four-shaft shredders are typically made of high-strength, wear-resistant materials such as alloy steel or high-hardness steel. This ensures they remain sharp even under prolonged, high-load operation, extending their service life. Their low speed operation also reduces noise, meeting modern environmental standards.

The four-shaft shredder's four rotating blades work in tandem, efficiently and reliably processing a variety of difficult-to-shred waste materials. It is a vital piece of equipment in waste recycling, resource reuse, and environmentally friendly processing.

| Model | Feed Opening Size | Power | Speed | Capacity | Blade Material | Weight | Dimensions |

|---|---|---|---|---|---|---|---|

| SHRED-1000 | 500 x 500 mm | 18 kW | 25 RPM | 500-1000 kg/h | Alloy Steel | 1500 kg | 2000 x 1200 x 2300 mm |

| SHRED-1500 | 600 x 600 mm | 22 kW | 20 RPM | 1000-1500 kg/h | Alloy Steel | 1800 kg | 2200 x 1300 x 2500 mm |

| SHRED-2000 | 800 x 800 mm | 30 kW | 18 RPM | 1500-2000 kg/h | High Strength Steel | 2200 kg | 2500 x 1500 x 2700 mm |

| SHRED-2500 | 1000 x 1000 mm | 37 kW | 15 RPM | 2000-2500 kg/h | Tungsten Steel Alloy | 2600 kg | 2800 x 1600 x 3000 mm |

| SHRED-3000 | 1200 x 1200 mm | 45 kW | 12 RPM | 2500-3000 kg/h | Tungsten Steel Alloy | 3000 kg | 3000 x 1700 x 3200 mm |

| SHRED-4000 | 1500 x 1500 mm | 55 kW | 10 RPM | 3000-4000 kg/h | High Hardness Steel | 3500 kg | 3500 x 2000 x 3400 mm |

*The output will vary according to different materials, feed particle size and other factors.

Save Time! Get A Detailed Quotation Quickly.