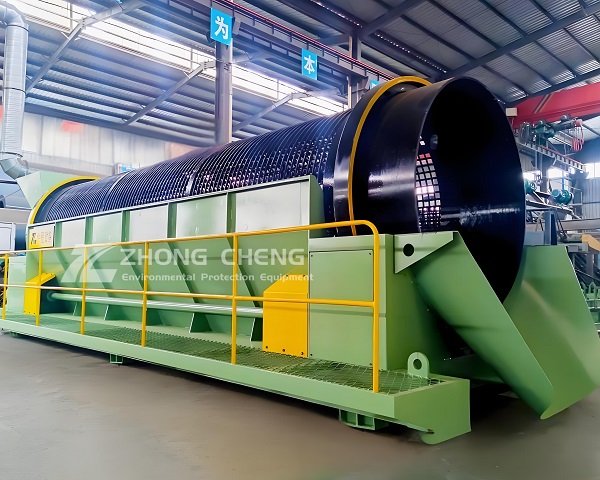

In the wave of "zero waste city" construction and circular economy development, efficient sorting of garbage is a key prerequisite for achieving "turning waste into treasure". The trommel screening machine developed by Zhengzhou Zhongcheng Environmental Protection, as the "pre-treatment pioneer" of the garbage treatment production line, has demonstrated irreplaceable advantages in complex working conditions with profound insight into the characteristics of garbage and continuous technological innovation, and has become the core equipment choice for many garbage treatment projects. Its advantages are not only reflected in the improvement of screening efficiency and accuracy, but also run through the entire life cycle dimensions such as equipment lifespan, operating costs, and environmental benefits.

In response to the typical characteristics of high moisture, high viscosity, and mixed composition of household waste, the primary breakthrough of Zhongcheng trommel screen is the adaptability bottleneck of traditional screening equipment. In most domestic waste disposal scenarios, kitchen waste accounts for as much as 50% -60%. Mixed waste is often compressed and transported in a "paste like" state, which can easily cause clogging of vibrating screens and other equipment, as well as material entanglement problems. The Zhongcheng trommel screen solves the pain point of this industry from the root by optimizing the core structural design: when the inclined installation drum rotates at a constant speed, the inner wall of the specially designed plate continuously lifts and throws the material, achieving full rolling and dispersion, and avoiding wet and sticky material agglomeration; Simultaneously equipped with a continuous self-cleaning comb or bouncing ball device, it can clean the entangled fibers and adhesive slurry in the sieve holes in real time during the rotation process, forming a "dynamic self-cleaning" effect. This design enables the equipment to not only efficiently process fresh household waste, but also cope with extremely complex materials such as landfill aged waste and decoration waste. In a certain aged waste management project, it operated continuously for 72 hours without blockage, and its screening stability far exceeded that of traditional equipment.

The dual breakthrough in processing scale and efficiency is the core advantage of Zhongcheng trommel screen in adapting to the needs of large-scale garbage treatment. The continuous production characteristics of garbage treatment plants impose strict requirements on the processing capacity and stability of equipment. Zhongcheng trommel screen adopts a modular design concept, with a single equipment processing capacity of 50-300t/h. By customizing the optimal ratio of drum diameter and length (such as using the specification of Φ 2.2m × 6m for large equipment), it ensures that materials have sufficient screening time in the drum without affecting the overall processing rhythm. The drive system is precisely configured according to the size of the equipment: large equipment adopts heavy-duty gear transmission to ensure high torque output; Flexible idler friction transmission is selected for small and medium-sized equipment to reduce operating noise and vibration, achieving 24-hour continuous and stable operation. In a municipal solid waste comprehensive treatment plant project, two intermediate trommel screens operate in parallel, processing 4800 tons of waste per day and increasing screening efficiency by 40% compared to the original equipment. This provides a stable supply of raw materials for subsequent RDF preparation and composting processes.

The multi-level precise screening and multi-purpose characteristics of one machine greatly enhance the value space of garbage resource utilization. Zhongcheng trommel screen can be designed with 2-4 levels of screen segmentation according to process requirements, and the mesh size can be flexibly customized from 3mm to 200mm to achieve gradient grading of materials. Taking typical household waste treatment as an example, the equipment can divide mixed waste into<10mm organic fine materials (used for composting or soil improvement), 10-50mm intermediate materials (rich in combustible materials such as plastics and paper), and>50mm sieved materials (large debris, concrete blocks, etc.) at once. This refined classification completely changes the limitations of traditional "extensive sorting", improving the efficiency of subsequent equipment such as air separation, magnetic separation, and AI robot sorting by more than 30%, and increasing the purity of recyclables from 65% to over 90%. In the scene of decoration waste treatment, the graded<15mm fine aggregate can be directly used for the preparation of recycled bricks, and the 15-40mm medium material can be used as roadbed material after impurity removal, with a resource recovery rate 25% higher than traditional processes.

Durable design and low operating costs provide assurance for long-term profitability of the project. The maintenance cost and downtime of garbage screening equipment directly affect project efficiency. The Zhongcheng trommel screen is reinforced in all aspects from material to structure: the screen plate is made of Hardox wear-resistant steel or NM400 wear-resistant plate, with a hardness of HB360 or above and a service life of 3-5 times that of ordinary Q235 steel plate; The key load-bearing components such as drum rings and supporting wheels have undergone carburizing and quenching treatment, significantly improving their wear resistance; The parts of the equipment that come into contact with materials are coated with stainless steel or special anti-corrosion coatings, effectively resisting the corrosion of wet garbage leachate. In terms of maintenance convenience, it adopts a split screen design, and the replacement of a single segment screen can be completed within 2 hours, saving 60% of maintenance time compared to traditional integral screens; The core components are selected from international first-line brands such as SKF bearings and Siemens reducers, reducing the failure rate to below 0.5 times per thousand hours. According to data from a certain garbage disposal project, the use of Zhongcheng trommel screen has reduced the average annual maintenance cost by about 180000 yuan, and the effective operating rate of the equipment remains above 95%.

The integration of intelligence and environmental design makes Zhongcheng trommel screen more in line with the development trend of modern garbage treatment. The equipment can be equipped with a PLC automatic control system, which enables precise adjustment of parameters such as speed and feed rate through a touch screen. It also has remote monitoring and fault alarm functions, reducing the need for manual intervention. A single person can complete the operation and management of multiple devices. In terms of energy consumption control, its transmission system adopts an efficient reduction mechanism, with a power reduction of 15% -20% compared to similar products. A 100t/h specification equipment consumes only 37kW of electricity per hour, saving over 300000 kWh of electricity annually. In terms of environmental performance, the fully sealed drum structure combined with negative pressure dust removal device effectively controls dust pollution during the screening process, with dust emission concentration below 10mg/m ³; The operating noise of the equipment is controlled below 75 decibels, far exceeding the national standard of 85 decibels, achieving "low-noise and dust-free" operation.

The full cycle service capability and customized solutions further enhance the application value of the equipment. Zhongcheng Environmental Protection is well aware that "there is no universal equipment, only adaptive solutions". Its engineering team will go deep into the project site, analyze specific requirements such as material composition, moisture content, and treatment targets, and customize screening cylinder parameters, screening stages, and supporting processes. From free material testing and scheme design in the early stage, to installation, debugging, and operation training in the middle stage, to spare parts supply and technical upgrades in the later stage, we provide a "one-stop" full lifecycle service. In a garbage treatment project in a certain county, in response to the high moisture content and large amount of garbage in the local area, the Zhongcheng team specially optimized the inclination angle of the drum and the layout of the copying plate, and designed a pre bag breaking device to improve the screening efficiency of the equipment by 22% compared to the standard solution, fully reflecting the core value of customized services.

In the wave of garbage resource utilization, Zhongcheng trommel screen has redefined the performance standards of garbage screening equipment with its comprehensive advantages of "strong adaptability, high efficiency, high precision, and low cost". It not only solves the technical difficulties of complex waste treatment, but also creates significant economic and environmental benefits for the project by improving resource recovery rates and reducing operating costs. From urban household waste treatment plants to renovation waste resource centers, from stale waste treatment sites to recyclable sorting bases, Zhongcheng trommel screens are becoming a solid force in promoting the construction of a "waste free city" and injecting sustained momentum into the development of circular economy.

Save Time! Get A Detailed Quotation Quickly.