The finger screen is a coarse screening device with parallel bars as the screen surface, which separates materials through vibration. It is suitable for large pieces of ore, coal, etc. It has good anti-blocking properties and can remove impurities. It is mostly used in the pre-processing links of mining, building materials and other industries.

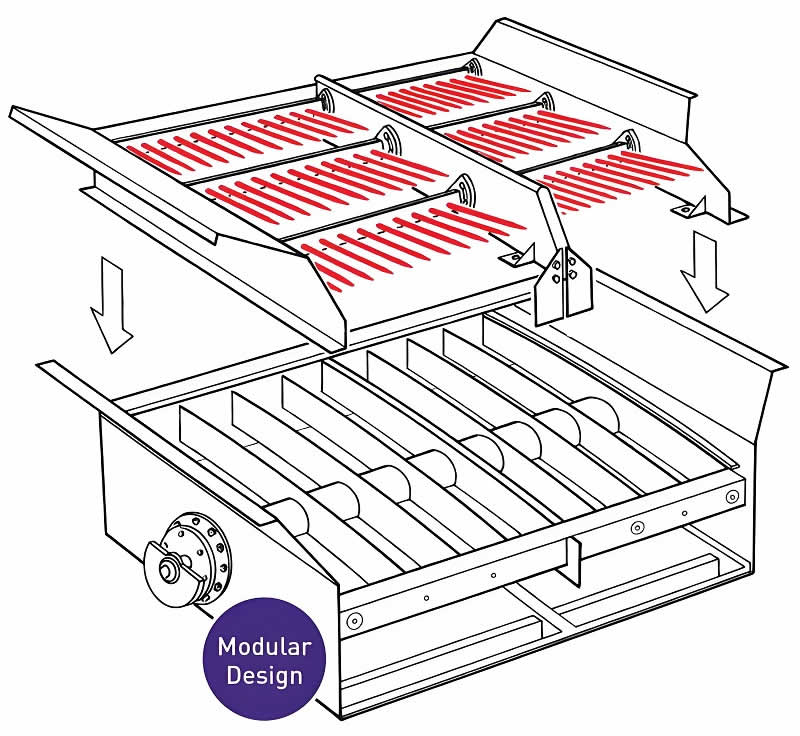

Finger screens are commonly used in coarse screening equipment in industries such as mining and building materials. Their core function is to pre-process bulk materials, remove impurities, and separate materials of varying particle sizes, thus reducing the burden on subsequent processing steps. Their structural design is simple and highly targeted: the screen surface consists of multiple parallel, wear-resistant bars, typically made of high-strength manganese steel or wear-resistant alloys. The spacing between the bars can be adjusted according to the required material particle size (typically suitable for bulk materials of 50-500mm), effectively preventing large impurities from clogging the screen surface.

During operation, the equipment utilizes directional vibrations generated by the vibrator, driving the finger screen surface in high-frequency reciprocating motion. Bulk materials such as ore and coal to be processed fall onto the screen surface through the feed inlet. The vibration forces materials that meet the required particle size to pass through the gaps between the bars and proceed to the next process. Larger materials or impurities exceeding the required particle size are then moved along the inclination of the screen surface and discharged from the discharge end, completing the coarse screening separation. Compared with ordinary screening equipment, the core advantage of the finger screen lies in its strong anti-clogging ability - the bar spacing is large and the surface is smooth, which is not easy to adhere to wet and sticky materials, and is suitable for ores and coals with high moisture content; at the same time, the wear-resistant bars have a long service life, the equipment operates with low noise and low maintenance costs. It is widely used in scenarios such as raw material pretreatment before mine crushing, sand and gravel grading in the building materials industry, and raw coal removal in the coal industry. It is an efficient and reliable equipment for coarse screening.

1. Select based on material characteristics: Determine the particle size and moisture content (e.g., wet and sticky ore) of the material to be screened, and choose a machine with appropriate bar spacing and vibration frequency to minimize impact on coarse screening efficiency and anti-clogging effectiveness.

2. Pay attention to bar material: Manganese steel or wear-resistant alloy bars are preferred to ensure resistance to wear and impact when handling bulk materials, extending the equipment's service life.

3. Determine specifications based on production capacity: Select a machine with appropriate dimensions based on the actual processing volume of the mining and building materials industries, ensuring that the equipment's capacity slightly exceeds the required level and is suitable for continuous operation.

4. Verify the vibration system: Choose a machine with high-frequency vibration and adjustable parameters to facilitate adjustment based on the material, ensuring stable and smooth operation and maintaining efficient screening.

5. Focus on structural stability: Choose a machine with a sturdy frame and precise connections, especially when handling heavy, bulky materials. This reduces malfunctions and ensures long-term reliable operation.

6. Consult manufacturer services: Select a manufacturer with established industry experience and confirm that they offer installation guidance and spare parts replacement services to reduce subsequent use and maintenance risks.

The rods are made of high-strength wear-resistant material, with a stable structure and impact resistance; the components are precise and durable, with few operating failures, and can provide long-term and stable service for coarse screening operations in mining and other industries.

It can be customized as needed, the rod spacing can be adjusted according to the material particle size, the equipment size can be changed according to the production capacity, and the wear-resistant material can be replaced to adapt to different coarse screening scenarios such as mining and building materials.

High-frequency vibration makes the coarse screening efficient and has a good anti-blocking effect; it is suitable for large pieces of wet and sticky materials, runs stably without jamming, and can continuously meet the operational needs of the mining and building materials industries.

It has strong anti-blocking properties and is suitable for large pieces of wet and sticky materials; the wear-resistant bars have a long service life, low operating noise and low maintenance costs; it can efficiently screen and remove impurities, and is widely used in pretreatment in mining, building materials and other industries.

The working principle of a finger screen revolves around the synergistic effect of high-frequency vibration and a finger screen surface. Its core function is to achieve coarse screening and impurity removal of bulk materials. The specific process can be divided into three steps:

First, the power drive is linked to the screen surface. The device is powered by an exciter, which drives the screen surface, composed of multiple parallel wear-resistant bars, in a directional, high-frequency reciprocating vibration. The screen surface is typically tilted at a certain angle, providing the basic power for material movement and separation. The bar spacing can be preset based on the particle size of the material being screened (suitable for bulk materials of 50-500mm).

Second, material screening and grading occurs. Large materials such as ore and coal to be processed are evenly deposited onto the vibrating finger screen through a feeder. Materials (or impurities) that meet the required particle size are screened through the gaps between the bars by the high-frequency vibration and fall into the receiving device below for further processing. However, bulky materials exceeding the required particle size (such as large ore chunks and hard impurities) cannot pass through the gaps between the bars. Due to the combined effects of vibration and gravity, they slide downward along the inclined screen surface and are discharged through the discharge port at the end of the screen, completing the coarse screening process.

Finally, anti-clogging and stability are ensured. The smooth surface of the wear-resistant bars and the high-frequency vibration effectively prevent wet and sticky materials from adhering to the screen surface, reducing the risk of clogging. Some models can adjust the vibration frequency to accommodate bulk materials of varying moisture and hardness, ensuring consistently efficient screening and impurity removal in coarse screening applications such as mining and building materials.

| No. | Model | Screen Size (mm) | Screen Area (m²) | Layers | Capacity (t/h) | Vibration Frequency (Hz) | Motor Power (kW) | Dimensions (mm) | Weight (kg) | Applicable Materials |

|---|---|---|---|---|---|---|---|---|---|---|

| 1 | BS-1230 | 1200 × 3000 | 3.6 | 1 | 50–100 | 4–6 | 7.5 | 3600 × 1900 × 1700 | 2200 | Sand, coal, ore pre-screening |

| 2 | BS-1530 | 1500 × 3000 | 4.5 | 1 | 80–150 | 4–6 | 11 | 3800 × 2100 × 1800 | 2600 | Construction aggregate, limestone, iron ore |

| 3 | BS-1836 | 1800 × 3600 | 6.5 | 1 | 100–200 | 4–6 | 15 | 4300 × 2400 × 1900 | 3200 | Granite, basalt, gangue |

| 4 | BS-1845 | 1800 × 4500 | 8.1 | 1 | 150–250 | 4–6 | 18.5 | 5100 × 2500 × 2000 | 3800 | Large stone, gravel, slag |

| 5 | BS-2045 | 2000 × 4500 | 9.0 | 1 | 200–300 | 4–6 | 22 | 5300 × 2600 × 2100 | 4200 | Coal mine, metal ore, pre-screening process |

| 6 | BS-2460 | 2400 × 6000 | 14.4 | 1 | 250–400 | 4–6 | 30 | 7000 × 3000 × 2200 | 5500 | Quarry, metallurgy, chemical raw materials |

| 7 | BS-3060 | 3000 × 6000 | 18.0 | 1 | 350–500 | 4–6 | 37 | 7200 × 3500 × 2300 | 6800 | Large ore, coal, construction waste |

*The output will vary according to different materials, feed particle size and other factors.

Save Time! Get A Detailed Quotation Quickly.