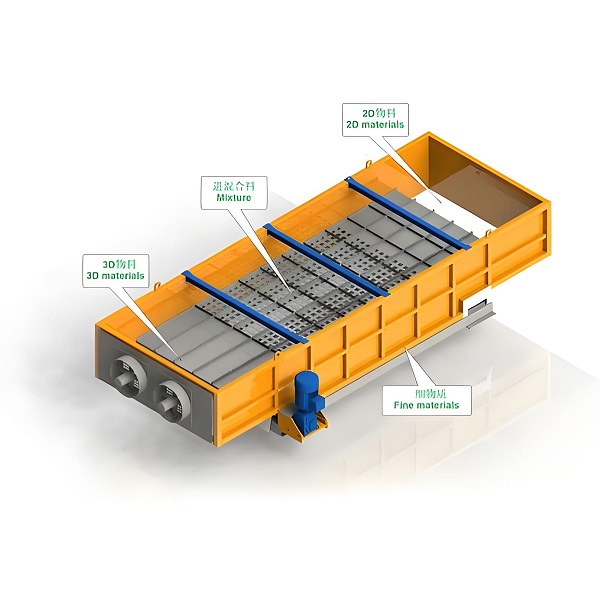

The ballistic screen is a highly efficient sorting device that utilizes the varying bouncing characteristics of different materials. Its screen plates are inclined or stepped and vibrate at high frequencies. It can separate plastic, paper, and masonry from waste, is suitable for wet and sticky solid waste, and offers excellent blockage resistance.

The ballistic screen is a highly efficient device designed for solid waste sorting. Its core operating principle is to separate materials by leveraging differences in density and elasticity. When materials fall onto a high-frequency vibrating inclined or stepped screen, low-density, high-elasticity materials (such as plastics and paper) are bounced upward along the screen's slope to the designated outlet. High-density, low-elasticity materials (such as bricks and metal blocks) bounce off the screen at a lower height, sliding down the screen to another channel, achieving precise separation of light and heavy materials.

The structural design is highly targeted: the inclined or stepped screen increases the contact area between the material and the screen surface. Combined with high-frequency, low-amplitude vibration, it promotes orderly material movement while preventing wet and sticky materials (such as kitchen scraps in household waste and wet soil in construction waste) from clogging the screen apertures. Its anti-clogging performance significantly outperforms traditional screening equipment.

In terms of application scenarios, the ballistic screen is widely used in construction waste recycling (separating concrete blocks from light impurities), household waste sorting (separating recyclables from inert waste), and the resource utilization of aged waste. The equipment can also adjust parameters such as the screen plate inclination angle and vibration frequency according to the characteristics of the processed material to adapt to different solid waste treatment needs, help improve solid waste recycling efficiency, and promote the process of environmental protection and resource utilization.

Select based on the characteristics of the material to be sorted: Identify the heavy and light components (e.g., plastics/bricks) and moisture content of the material, and choose a machine model with appropriate screen plate spacing and vibration parameters to avoid impacts on sorting accuracy due to material variations.

Focus on screen plate design and material: Prefer inclined/stepped screen plates made of wear-resistant stainless steel or polyurethane to ensure blockage resistance and durability, extending the equipment's service life in wet and sticky solid waste processing.

Determine specifications based on production capacity and application scenarios: Choose a heavy-duty machine for construction waste and a small- to medium-sized machine for domestic waste, ensuring that the equipment's processing capacity slightly exceeds actual needs and is suitable for continuous operation.

Check the stability of the vibration system: Choose a machine with high-frequency, low-amplitude vibration and adjustable parameters to facilitate adjustments based on the material, ensuring stable sorting results and minimizing malfunctions during long-term operation.

Focus on auxiliary functions and environmental protection: Prefer models with dust removal and noise reduction devices, especially for domestic waste processing, to reduce pollution and meet environmental requirements.

Refer to manufacturer cases and after-sales service: Select manufacturers with solid waste treatment industry cases, and confirm that they provide trial operation, installation training and supply of wearing parts to reduce the risk of subsequent use.

The screen plate is made of wear-resistant material, with a stable structure and impact resistance; the vibration system is precise and durable, and the sorting accuracy is long-lasting and stable; the accessories are of high quality, the failure rate is low, and good performance is maintained during long-term operation.

The ballistic screen can be customized as needed, and the screen plate spacing and vibration parameters can be adjusted according to the material characteristics; the equipment specifications can be changed according to production capacity, and dust removal and noise reduction functions can be added to adapt to different processing scenarios such as garbage and construction waste.

It has high sorting accuracy and can quickly separate light and heavy materials; it is suitable for wet and sticky solid waste without clogging, has stable operation and low energy consumption, and can operate continuously and efficiently to meet the needs of garbage and construction waste treatment.

The screen plate is anti-blocking and wear-resistant; it is suitable for wet and sticky solid waste and has high sorting accuracy; the parameters are adjustable, and it can also be equipped with dust removal and noise reduction to help protect the environment, and is suitable for garbage and construction waste treatment.

The core operating principle of a ballistic screen is to utilize the differences in density and elasticity of different materials, combined with a special screen plate structure and vibration, to achieve precise separation of light and heavy materials. The overall process can be divided into three key steps:

First, material feeding and initial contact. The material to be processed (such as domestic waste and construction waste) is evenly conveyed to the screen surface through a feed device. The screen surface is often designed with an inclined or stepped shape, and driven by an exciter to generate high-frequency, low-amplitude vibrations, providing the driving force for material separation and ensuring orderly movement along the screen surface to prevent accumulation.

Second, the core sorting step occurs. When materials land on the vibrating screen surface, they exhibit different motion states due to their varying physical properties. Light materials with low density and good elasticity (such as plastics and paper) are subjected to the vibration force of the screen surface and bounce high and move forward quickly. They move upward along the inclined direction of the screen surface and eventually enter the light material collection channel. Heavy materials with high density and low elasticity (such as bricks and metal blocks) bounce low and move slowly. Due to gravity, they slide along the screen surface and enter the heavy material outlet, completing the initial separation of light and heavy materials. Finally, there's sorting optimization and auxiliary support. Some models adjust parameters like the screen's tilt angle and vibration frequency to suit different material characteristics (for example, wet and sticky materials require enhanced vibration to prevent clogging). Furthermore, special screen surface patterns or spacing can further reduce clogging with wet and sticky materials, ensuring continuous and stable operation of the equipment and ultimately achieving efficient and accurate solid waste sorting.

| No. | Model | Screen Size (mm) | Screen Area (m²) | Layers | Capacity (t/h) | Vibration Frequency (Hz) | Motor Power (kW) | Dimensions (mm) | Weight (kg) | Applicable Materials |

|---|---|---|---|---|---|---|---|---|---|---|

| 1 | TQ-800 | 800 × 2000 | 1.6 | 1 | 2–8 | 14–16 | 1.5 | 2200 × 1000 × 1200 | 450 | Flour, chemical powder, pharmaceutical powder |

| 2 | TQ-1000 | 1000 × 2500 | 2.5 | 1 | 3–10 | 14–16 | 2.2 | 2700 × 1200 × 1300 | 620 | Food powder, resin powder, ceramic powder |

| 3 | TQ-1200 | 1200 × 3000 | 3.6 | 1 | 5–15 | 14–16 | 3.0 | 3200 × 1400 × 1400 | 850 | Sand, mineral powder, plastic granules |

| 4 | TQ-1500 | 1500 × 3500 | 5.3 | 1 | 8–20 | 14–16 | 4.0 | 3800 × 1700 × 1500 | 1100 | Quartz sand, carbon powder, abrasives |

| 5 | TQ-1800 | 1800 × 4000 | 7.2 | 1 | 10–25 | 14–16 | 5.5 | 4300 × 2000 × 1600 | 1450 | Fertilizer, coal powder, building materials |

| 6 | TQ-2000 | 2000 × 4500 | 9.0 | 1 | 15–30 | 14–16 | 7.5 | 4800 × 2200 × 1700 | 1800 | Lime powder, cement, metallurgical powder |

| 7 | TQ-2400 | 2400 × 5000 | 12.0 | 1 | 20–40 | 14–16 | 11 | 5200 × 2500 × 1800 | 2200 | Ore, coal, sand and gravel powder |

*The output will vary according to different materials, feed particle size and other factors.

Save Time! Get A Detailed Quotation Quickly.