A magnetic separator is a device that uses a magnetic field to separate materials. It uses permanent magnets or electromagnetics to construct a magnetic field, and can efficiently separate magnetic and non-magnetic materials. It is suitable for ores and waste slag, and is widely used in mine purification and environmentally friendly iron removal.

Magnetic separators are specialized equipment that use magnetic fields to separate magnetic and non-magnetic materials. They are widely used in mining, metallurgy, environmental protection, and building materials industries. They are primarily used for ore purification (such as magnetite enrichment), iron removal from industrial waste (such as iron chips from construction waste), and material purification. They are key equipment for improving resource utilization and product quality.

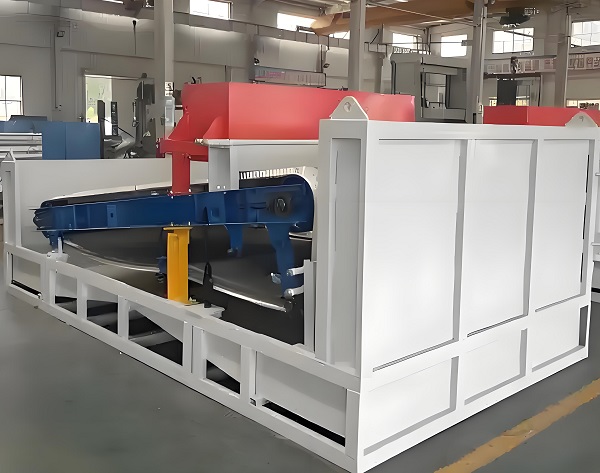

The core structure of a magnetic separator consists of a magnetic system, working components, and a conveying system. The magnetic system can be either permanent magnet (commonly using materials such as neodymium iron boron, which offers low energy consumption and simple maintenance) or electromagnetic (with adjustable magnetic strength to accommodate complex separation requirements). The working components, typically drums, magnetic rollers, or magnetic disks, are the core area of the magnetic field. The conveying system is responsible for evenly feeding the materials to be separated into the magnetic field, ensuring continuous separation.

Based on their application and structural differences, magnetic separators can be categorized as drum-type (suitable for coarse and medium-grained materials, such as ore separation), roller-type (suitable for fine-grained materials, such as iron powder purification), and disc-type (suitable for rare metal separation). During operation, when the material to be sorted enters the magnetic field, magnetic particles are attracted to the surface of the working component and transported to the discharge area, while non-magnetic particles fall directly to the surface, achieving efficient separation.

This equipment combines high sorting accuracy, stable operation, and controllable energy consumption. It can meet the needs of large-scale mining production and is also suitable for refined iron removal operations in the environmental protection field, providing important support for resource recycling and green production.

1. Determine the magnetic system based on the material's magnetic properties: Identify the magnetic strength of the material to be sorted (e.g., strongly magnetic minerals vs. weakly magnetic minerals) and select a permanent magnet or electromagnetic magnetic system. For strongly magnetic materials, choose a conventional permanent magnet, while for weakly magnetic materials, choose a strong magnetic machine.

2. Select the equipment type based on particle size: For coarse-grained materials (e.g., ore lumps), choose a drum magnetic separator; for fine-grained/powdered materials (e.g., iron powder), choose a roller or disc magnetic separator to avoid particle size discrepancies that could affect sorting results.

3. Determine equipment specifications based on production capacity: Based on the actual processing volume of industries like mining and metallurgy, select a machine with a corresponding processing capacity, ensuring that production capacity slightly exceeds demand and accommodates continuous production.

4. Focus on magnetic strength and stability: Select a machine with consistently stable magnetic strength that meets standards to avoid rapid magnetic strength decay. Also, verify the uniformity of the magnetic system distribution to ensure sorting accuracy.

5. Focus on structure and wear resistance: Select a machine with a drum/magnetic roller made of wear-resistant material (e.g., stainless steel) and a stable frame, especially when processing high-hardness materials, to minimize component wear.

6. Refer to the manufacturer's services and case studies: Select a manufacturer with industry-leading application cases and confirm that they offer installation, commissioning, and magnetic system maintenance services to reduce future use and repair risks.

Made of high-quality materials, the magnetic strength lasts and does not decay; the roller/frame is made of wear-resistant materials to resist loss, and the structure is precise and has few faults.

It can be customized as needed, with the magnetic strength adjusted according to the material's magnetism, the equipment type selected according to the particle size, the specifications changed according to production capacity, and protective components added to adapt to different sorting scenarios such as mining and environmental protection.

It has high sorting accuracy and can efficiently separate magnetic materials; it is suitable for strong and weak magnetic minerals, operates stably without jamming, and can sustainably meet the purification needs of mining, metallurgy and other fields.

It can efficiently separate magnetic and non-magnetic materials, the magnetic strength can be adjusted to suit different minerals, it operates stably and has low energy consumption, and is widely used for material purification in mining, metallurgy, environmental protection and other fields.

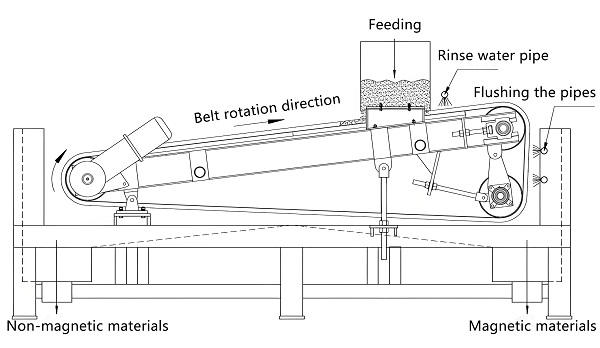

The operating principle of a magnetic separator is centered around "magnetic field action + mechanical conveying." It utilizes the difference in force exerted on magnetic and non-magnetic materials in a magnetic field to achieve efficient separation. The specific process can be divided into three steps:

First, magnetic field generation and material conveying. The equipment uses permanent magnets or electromagnets to generate a stable magnetic field (magnetic strength can be adjusted as needed). The magnetic field is primarily concentrated on the surfaces of core working components, such as drums and magnetic rollers. The material to be separated (such as ore or waste residue) is evenly conveyed above the working components through a feeder and then, as the components rotate, enters the magnetic field.

Second, magnetic material adsorption and separation occurs. Once in the magnetic field, magnetic particles (such as iron filings or magnetite) in the material are attracted by the magnetic field and firmly adhere to the working components. As the components rotate, they are transported to the discharge area outside the magnetic field. Non-magnetic particles (such as sand and gravel, waste residue) are not affected by the magnetic field and are discharged directly from the lower discharge port under the action of gravity, completing the initial separation.

Finally, the magnetic material is discharged and collected. When the working component that attracts magnetic particles moves out of the magnetic field, the magnetic field's attraction disappears, and the magnetic particles fall off under the influence of gravity or the help of scrapers, falling into the magnetic material collection channel, ultimately achieving complete separation of magnetic and non-magnetic materials. This principle is suitable for materials with different magnetic strengths and weaknesses and is widely used in scenarios such as mine purification and environmentally friendly iron removal.

| No. | Model | Drum Diameter (mm) | Drum Length (mm) | Capacity (t/h) | Magnetic Induction (mT) | Motor Power (kW) | Rotation Speed (r/min) | Dimensions (mm) | Weight (kg) | Applicable Materials |

|---|---|---|---|---|---|---|---|---|---|---|

| 1 | CTB-600×900 | 600 | 900 | 8–15 | 120–180 | 1.1 | 35 | 1500 × 1200 × 1100 | 850 | Iron ore, hematite, magnetite |

| 2 | CTB-750×1200 | 750 | 1200 | 10–25 | 150–200 | 1.5 | 35 | 1800 × 1350 × 1200 | 1100 | Iron powder, ferric oxide, slag powder |

| 3 | CTB-900×1800 | 900 | 1800 | 20–45 | 160–220 | 2.2 | 30 | 2400 × 1500 × 1250 | 1450 | Iron sand, magnetic minerals, metal ore |

| 4 | CTB-1050×2100 | 1050 | 2100 | 30–60 | 180–250 | 3.0 | 28 | 2800 × 1600 × 1300 | 1800 | Iron concentrate, quartz sand, manganese ore |

| 5 | CTB-1200×2400 | 1200 | 2400 | 40–75 | 200–300 | 4.0 | 25 | 3100 × 1750 × 1400 | 2300 | Iron ore, ilmenite, limonite |

| 6 | CTB-1500×3000 | 1500 | 3000 | 60–100 | 220–350 | 5.5 | 22 | 3800 × 1900 × 1500 | 3100 | Iron sand, magnetic ore, garnet |

| 7 | CTB-1800×3600 | 1800 | 3600 | 80–150 | 250–400 | 7.5 | 20 | 4500 × 2200 × 1600 | 3900 | High-grade iron ore, rare metal ore, beneficiation line |

*The output will vary according to different materials, feed particle size and other factors.

Save Time! Get A Detailed Quotation Quickly.