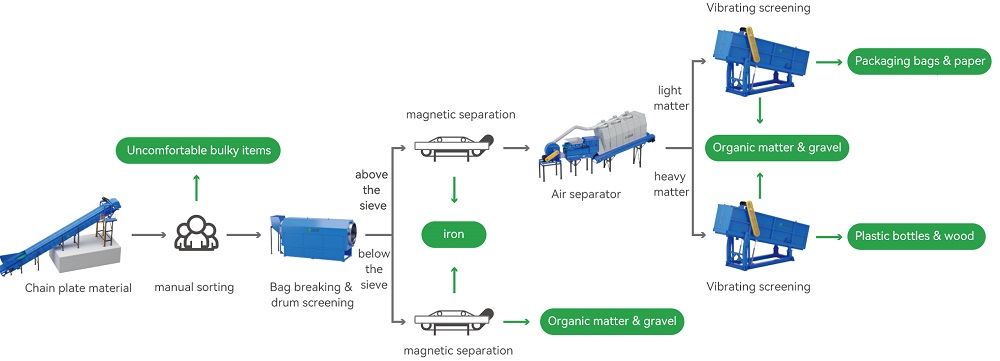

Thailand's domestic waste screening and treatment system primarily provides comprehensive treatment for mixed domestic waste generated in cities and towns. Through a multi-stage process involving crushing, screening, air separation, magnetic separation, and photoelectric separation, the system effectively separates recyclables, organic matter, and inorganic materials from the waste. A drum screen or vibrating screen is used at the front end for particle size classification, removing large particles and fine soil. A wind-powered separator separates light and heavy materials, such as plastic film, paper, glass, and metal, from each other. Magnetic separation and eddy current separation equipment recover metal resources such as iron and aluminum. The organic fraction can be further processed through composting or anaerobic fermentation to produce organic fertilizer or biogas energy. The entire system is automated, minimizing manual intervention and adapting to Thailand's high temperature and high humidity climate. This system not only effectively reduces landfill volume but also promotes resource recycling, aligning with the Thai government's "zero waste" and sustainable development strategies and serving as a crucial component of modern waste management.

| Equipment Name | Typical Power / Motor | Typical Capacity / Throughput | Main Function / Remarks |

|---|---|---|---|

| Trommel / Rotary Screen | 30–80 kW | 20–60 t/h | Coarse screening, removal of large items, size classification |

| Vibrating Screen | 10–40 kW | 5–40 t/h | Fine particle screening and grading |

| Double-shaft Shredder | 50–150 kW | 5–30 t/h | Shredding large waste into smaller pieces for downstream processing |

| Single-shaft Shredder | 30–100 kW | 5–25 t/h | Auxiliary shredding, volume reduction |

| Air Separator / Air Classifier | 20–50 kW | 15–35 t/h | Separates light materials (plastics, paper) from heavier fractions |

| Magnetic Separator | 5–25 kW | 1–10 t/h | Separates ferrous metals from mixed waste |

| Electrostatic Separator | 5–15 kW | 1–5 t/h | Separates non-ferrous metals and plastics based on charge |

| Screw Conveyor / Belt Conveyor | 5–20 kW | — | Transfers materials between units |

| High-speed Centrifuge / Dewatering Unit | 10–50 kW | 1–15 t/h | Dewatering of wet organic fractions |

| Press / Squeezer | 20–80 kW | 1–10 t/h | Pressing wet residues to reduce moisture and weight |

Thailand's domestic waste screening and treatment system boasts significant advantages, including high efficiency, environmental friendliness, and intelligent technology. Its rationally designed structure is suited to Thailand's high temperature and high humidity climate, and its corrosion-resistant and anti-clogging equipment ensures long-term stable operation. Its multi-stage screening and sorting process enables precise sorting of mixed waste, including organics, plastics, metals, paper, glass, and soil, maximizing resource utilization. The modular design of the equipment facilitates transportation, installation, and maintenance, allowing for flexible configuration based on waste composition in different regions. The system utilizes automated control and intelligent monitoring technologies to reduce manual operations and improve processing efficiency and safety. Furthermore, the system effectively reduces landfill volume and leachate generation, minimizing odor and secondary pollution. The separated organic fraction can be composted or anaerobic fermented for energy recovery, while recyclables are recycled. Overall, the system achieves the goals of "reduction, resource utilization, and harmlessness," advancing Thailand's solid waste management towards a circular economy and sustainable development.

Save Time! Get A Detailed Quotation Quickly.