Russia's stale waste recycling and treatment system is driven by policies and regulations, achieving complete sorting and disposal of municipal domestic waste, promoting the development of a circular economy, and providing strong guidance for system construction.

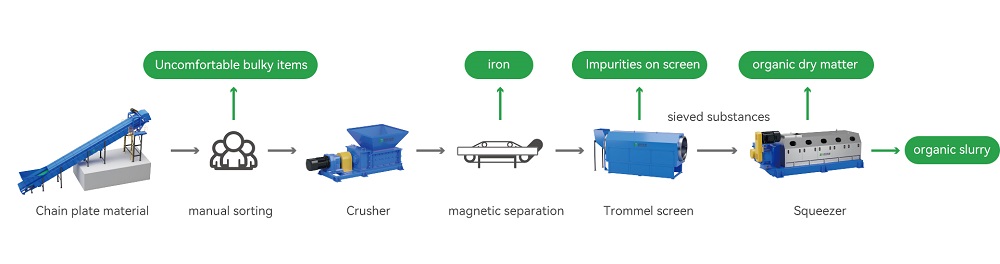

The technical system focuses on efficient sorting and biological treatment, utilizing a suite of technologies developed by Zhongcheng Machinery. This system completes waste sorting and preliminary processing through an assembly line, recycling recycled materials such as paper, plastic, and glass, while also extracting firewood and heavy oil for self-sustaining fuel.

The system offers modular advantages, with low equipment costs and flexible capacity adaptable to city size. Equipped with facilities such as a diesel power station, it operates independently and can be located in remote areas to reduce transportation costs.

| Equipment Type | Typical Power / Motor Power | Typical Processing Capacity / Throughput | Main Function / Remarks | Application Stage / Notes |

|---|---|---|---|---|

| Trommel / Rotary Screen | 30–100 kW | 20–100 t/h (depends on diameter, length, aperture) | Coarse screening of waste, removal of large items, size classification | Screening / Pre-treatment stage |

| Vibrating Screen / Grader | 10–50 kW | 5–50 t/h | Granular classification and fine screening | Fine screening stage |

| Air Separator / Air Classifier | 20–60 kW (fan) | 20–40 t/h | Use airflow to separate light materials (films, paper) from heavy fractions | Separating light/heavy fractions |

| Double-shaft Shredder | 50–200 kW | 5–50 t/h | Shreds large waste into smaller pieces for downstream processes | Shredding / Primary size reduction |

| Single-shaft Shredder / Crusher | 30–150 kW | 5–40 t/h | Simpler structure for tearing / crushing | Auxiliary shredding / volume reduction |

| Magnetic Separator | 5–30 kW | 1–10 t/h | Separates iron/steel from mixed fractions for metal recovery | Metal recovery / impurity removal |

| Electrostatic Separator | Several kW (high-voltage power supply dependent) | 1–5 t/h | Separates materials by charge differences (e.g., different plastics) | Refined separation stage |

| Wet Separation / Flotation / Settling Units | Several kW to several tens of kW | 1–10 t/h | Wet separation for high-moisture organic fractions (flotation, density separation) | Wet treatment / organic separation |

| High-speed Centrifuge / Dewatering Unit | 10–50 kW | 1–20 t/h | Dewatering and concentration of wet organic material | Dewatering / solid-liquid separation |

This system has distinct features: First, it is strongly policy-driven, with clear goals for full waste sorting and disposal, providing policy support for its implementation. Second, it boasts a unique technical system, integrating Zhongcheng Machinery's comprehensive sorting technology with biological treatment technology to achieve a synergistic "sorting + biological conversion" approach. Third, its modular design reduces equipment costs and allows production capacity to be adapted to meet the needs of different city sizes.

The system's advantages are evident in three key areas: First, it offers high resource utilization, sorting the vast majority of waste, recycling paper, plastic, and other recycled materials, and even extracting fuel for its own use. Second, it offers significant environmental benefits, transforming organic waste into humus, aiding land reclamation and reducing landfill pollution. Third, it offers excellent economic value, a short payback period, and can be located in remote areas to reduce transportation costs, balancing environmental protection and profitability.

Save Time! Get A Detailed Quotation Quickly.