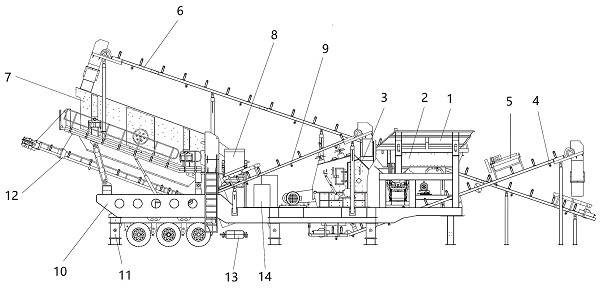

The tire type mobile screening station uses tires as walking components, allowing for flexible transitions. It can efficiently screen materials such as sand, gravel, and ore, adapt to various working conditions, and is widely used in material separation operations in fields such as construction, mining, and road construction.

The tire type mobile screening station is an integrated and movable material screening equipment, which uses a tire chassis as the walking system and is equipped with flexible traction devices. It does not require complex infrastructure and can quickly adapt to site transfer, meeting the needs of alternating construction at multiple work points.

The core screening system of the equipment adopts a multi-layer vibrating screen design, which can flexibly replace the screen according to the material particle size requirements, adapt to various materials such as sand and gravel, ore, coal, construction waste, etc. The screening efficiency can reach 80-150 tons/hour, with high grading accuracy, effectively reducing material waste. At the same time, its intelligent control system can monitor the operating status in real time, and the one click start stop operation is simple, reducing labor costs; The overall structure is compact, occupying small space, and can operate stably in complex environments such as narrow construction sites and mountainous mining areas.

With high mobility, strong adaptability, and efficient screening capabilities, this equipment is widely used in fields such as construction, mining, road construction, and solid waste resource utilization. It provides convenient solutions for material pretreatment and grading operations, helping projects improve construction efficiency and reduce transportation costs.

1. Clarify material and production capacity requirements: Select the screen type based on the particle size and humidity of the materials to be screened (sand/ore, etc.), and determine the suitable production capacity within 80-150 tons/hour according to the daily processing capacity of the project.

2. Evaluate the adaptability of mobility and site: prioritize equipment with flexible traction and strong tire load-bearing capacity to ensure smooth transition and stable parking in complex scenarios such as mountainous areas and narrow construction sites.

3. Pay attention to screening accuracy and efficiency: Look at the number of layers of the vibrating screen (multi-layer is better) and the vibration frequency adjustment function to ensure high grading accuracy, reduce material waste, and match the production rhythm of the project.

4. Evaluate intelligence and operational convenience: Choose an intelligent control system with real-time operation monitoring and one click start stop to reduce the difficulty of manual operation and facilitate timely detection of equipment failures.

5. Verify equipment durability and after-sales service: Check the materials of core components such as screen mesh and chassis (wear-resistant materials are preferred), and confirm whether the manufacturer provides timely maintenance and parts replacement services.

6. Compare energy consumption and environmental indicators: Prioritize low-energy motors. If the project has environmental requirements, it is necessary to confirm whether the equipment meets relevant standards for dust and noise emissions to avoid environmental risks.

The core components are made of wear-resistant materials, and the chassis has strong load-bearing capacity; Compact and stable structure, anti loss vibration system; Sealed design provides excellent fault prevention, long-term stable operation, reduces maintenance frequency, and has a long service life.

Customizable screen specifications to suit different materials as needed; Ability to adjust production capacity to match project requirements; Intelligent monitoring and environmental protection devices can also be added, and the chassis design can be adapted to special work sites.

High screening efficiency, processing capacity up to standard, and precise grading; Stable operation, the vibration system is not prone to failure under complex working conditions; Flexible and fast transition, adaptable to various materials and work scenarios, with timely operational response.

Flexible mobility and adaptability to complex environments; High screening accuracy, strong efficiency, and the ability to handle a variety of materials; Intelligent and convenient operation, good durability, low energy consumption, and compliance with environmental requirements, with a wide range of applicable scenarios.

The tire type mobile screening station is first transferred to the work site through a traction device, and after debugging and stabilizing, the equipment is started. The material to be screened enters through the feeding port and is transported at a constant speed by the conveyor belt to the vibrating screening system.

The vibration system is driven by a motor to rotate an eccentric block, generating directional vibration force that causes the multi-layer screen mesh to continuously vibrate. The material continuously rolls and moves on the sieve due to vibration, and materials smaller than the sieve aperture pass through the sieve and fall into the corresponding hopper in the lower layer; Materials larger than the aperture are discharged along the inclined surface of the sieve, becoming graded materials of different particle sizes.

At the same time, the intelligent control system monitors real-time parameters such as conveyor belt speed and vibration frequency, and can adjust vibration intensity according to material characteristics to ensure screening accuracy. Finally, the graded finished materials are discharged through their respective discharge ports, completing the entire screening process and suitable for efficient separation of various materials such as sand, gravel, and ore.

| No. | Model | Screen Layers | Screen Area (m²) | Capacity (t/h) | Max Feeding Size (mm) | Engine Power (kW) | Travel Speed (km/h) | Dimensions (mm) | Weight (t) | Applicable Materials |

|---|---|---|---|---|---|---|---|---|---|---|

| 1 | YKS-1230T | 2 | 3.6 | 50–150 | ≤150 | 74 | 1.0 | 11500 × 2800 × 3400 | 25 | Construction waste, sand and gravel aggregates |

| 2 | YKS-1540T | 2 | 6.0 | 80–200 | ≤200 | 92 | 1.0 | 12500 × 3000 × 3500 | 29 | Coal, ore, limestone |

| 3 | YKS-1848T | 3 | 8.6 | 100–250 | ≤250 | 110 | 1.0 | 13200 × 3200 × 3600 | 32 | Granite, basalt, river pebbles |

| 4 | YKS-2060T | 3 | 12.0 | 150–350 | ≤300 | 132 | 1.2 | 13800 × 3400 × 3800 | 36 | Quartz sand, manufactured sand, gangue |

| 5 | YKS-2260T | 3 | 13.2 | 180–400 | ≤350 | 160 | 1.2 | 14500 × 3500 × 3900 | 40 | Iron ore, slag, aggregate screening |

| 6 | YKS-2460T | 3 | 14.4 | 200–450 | ≤400 | 185 | 1.3 | 15000 × 3600 × 4000 | 45 | Construction aggregates, recycled concrete |

| 7 | YKS-3060T | 3 | 18.0 | 250–550 | ≤450 | 200 | 1.3 | 15800 × 3800 × 4200 | 50 | Large ores, quarry materials, coal raw materials |

*The output will vary according to different materials, feed particle size and other factors.

Save Time! Get A Detailed Quotation Quickly.