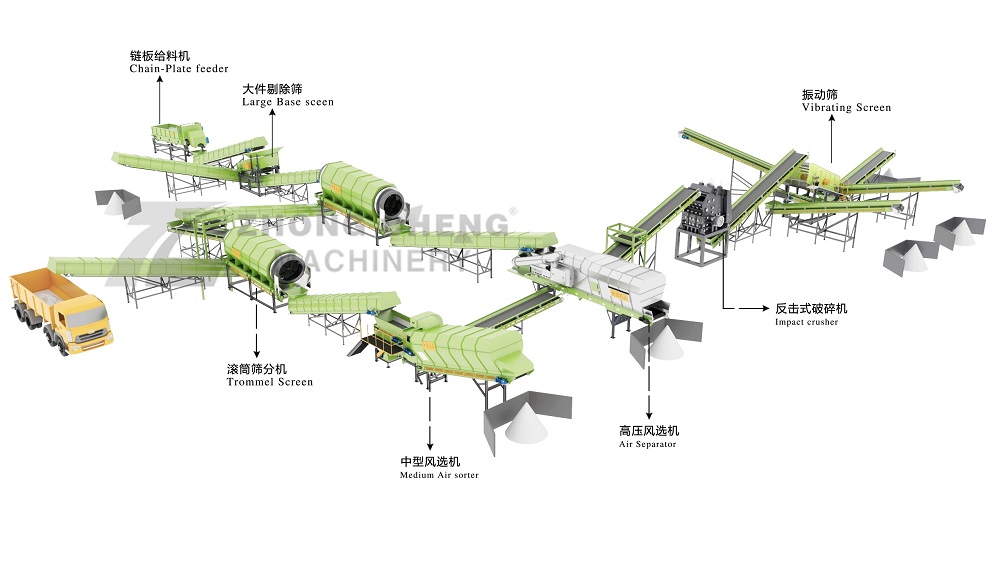

The renovation waste crushing and screening system is an integrated device designed specifically for processing renovation waste. Its core components include a crushing module, a screening module, a sorting module, and a conveying module. It is suitable for a variety of renovation waste types, including tiles, cement blocks, wood, and metal.

During operation, the waste is first crushed to a uniform particle size by a jaw or impact crusher. A vibrating screen then separates the material according to particle size. A magnetic separator separates metal impurities, and an air separator separates lightweight combustibles. The system can flexibly adjust the crushing size and screening accuracy to meet different recycling needs, such as converting crushed stone into concrete aggregate or pulverizing wood for fuel.

The system's compact footprint and portability make it suitable for small and medium-sized processing locations, such as residential areas and renovation sites. It reduces waste collection costs and achieves a recycled aggregate recovery rate of over 80%, alleviating landfill pressure while promoting the resource utilization of renovation waste, aligning with environmental protection and the circular economy.

| Equipment Name | Typical Power / Motor | Typical Capacity / Throughput | Main Function / Remarks |

|---|---|---|---|

| Jaw Crusher / Single-shaft Crusher | 50–150 kW | 10–50 t/h | Primary crushing of concrete, bricks, tiles, and other large construction debris |

| Impact Crusher / Hammer Crusher | 75–200 kW | 15–60 t/h | Secondary crushing and shaping of concrete, stones, tiles |

| Mobile Shredder / Double-shaft Shredder | 50–200 kW | 5–40 t/h | Shredding mixed debris, wood, plastics, and gypsum boards |

| Trommel / Rotary Screen | 30–100 kW | 20–80 t/h | Screening by particle size, separating fine and coarse fractions |

| Vibrating Screen | 10–50 kW | 5–40 t/h | Further particle grading for sorting recycled aggregates |

| Magnetic Separator | 5–30 kW | 1–10 t/h | Separation of ferrous metals from construction debris |

| Air Separator / Air Classifier | 20–60 kW | 10–30 t/h | Separation of light materials like plastics, paper, insulation |

| Screw Conveyor / Belt Conveyor | 5–20 kW | — | Transport of materials between equipment units |

| High-speed Centrifuge / Dewatering Unit | 10–50 kW | 1–15 t/h | Dewatering wet construction sludge or mixed residues |

| Dust Collector / Air Filtration Unit | 10–50 kW | — | Reduce dust emissions during crushing and screening |

This system has distinct features: First, its integrated design combines four core modules: crushing, screening, sorting, and conveying. This eliminates the need for additional equipment, enabling one-stop processing of renovation waste and streamlining the workflow. Second, it offers high flexibility, enabling the crushing size to be controlled by adjusting crusher parameters, and the vibrating screen accuracy to be adjusted on demand, adapting to diverse recycling needs, such as aggregate processing and fuel production. Third, its wide adaptability allows for a wide range of scenarios. Its compact design occupies a small footprint and supports mobile operation, allowing it to be deployed within residential areas or directly at renovation sites, reducing waste transfer.

The system's advantages are evident in three key areas: First, its high resource recovery rate. Utilizing magnetic separation and air separation technologies, it precisely separates metals and lightweight combustibles, achieving a recycled aggregate recovery rate exceeding 80%, significantly improving resource recycling. Second, its cost-effectiveness is excellent, as on-site processing reduces waste collection and landfill costs, and the equipment's low operating energy consumption lowers overall costs over the long term. Third, its significant environmental impact reduces the amount of renovation waste landfilled and mitigates soil and environmental pollution risks. This system aligns with environmental protection policies and the demands of the circular economy, contributing to the development of green cities.

Save Time! Get A Detailed Quotation Quickly.