In today's era of increasingly scarce resources and ever-rising environmental protection requirements, the efficient development and comprehensive utilization of mineral resources has become a core issue for industrial development. Magnetic separators, as devices that use magnetic fields to separate materials, play an irreplaceable role in mining, metallurgy, chemical, building materials, and even environmental protection industries due to their high efficiency, low energy consumption, and environmental friendliness. They are not only an important means of improving ore grade but also a key technological equipment for promoting resource regeneration and green manufacturing, with profound significance for achieving energy conservation, emission reduction, and sustainable development.

With the rapid development of modern industrial technology, the comprehensive utilization of mineral resources and environmental protection have become important issues in the mining sector. Magnetic separators, as highly efficient separation equipment, play an irreplaceable role in mineral processing, metallurgy, chemical, building materials, and environmental protection industries due to their unique separation principle and wide applicability. Magnetic separation technology not only improves the utilization rate of ore resources but also effectively reduces resource waste and environmental pollution, making it an important means of achieving green and efficient production.

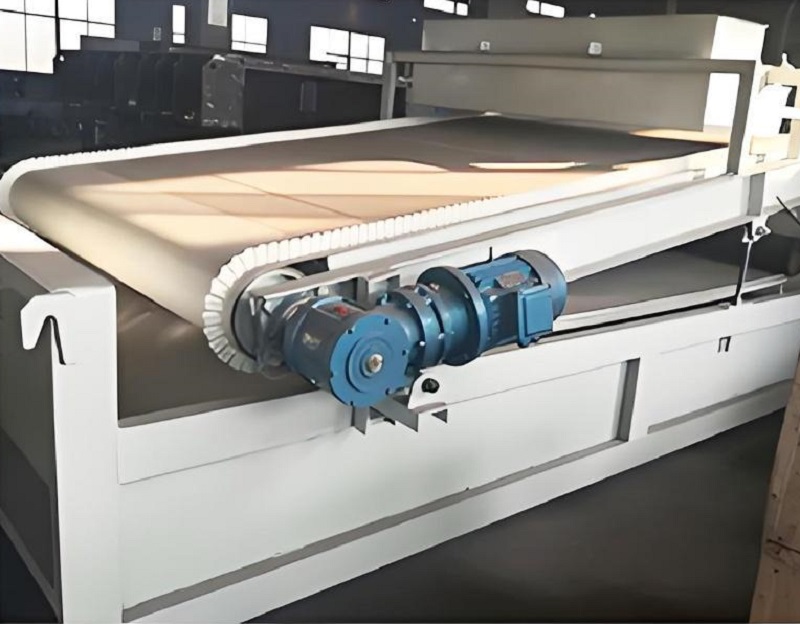

A magnetic separator typically consists of a feeding device, a magnetic system, a cylinder or belt structure, and a discharge system. After the material is evenly fed into the magnetic separation zone by the feeding device, the magnetic particles are adsorbed onto the surface of the magnetic drum or the conveyor belt. As the equipment moves to the non-magnetic zone, they are released from the magnetic field and discharged by the unloading device, thus achieving separation.

Main Functions of Magnetic Separators

1. Improving Ore Grade

The primary function of magnetic separators is to remove impurities from ores and improve the grade of concentrates. In iron ore beneficiation, magnetic separation can effectively separate magnetic minerals with high iron content and reduce the content of non-magnetic gangue minerals, thereby significantly improving ore quality and smelting efficiency.

2. Comprehensive Resource Utilization

For associated minerals, low-grade ores, and tailings resources, magnetic separation technology can effectively recover valuable metals. For example, in copper, nickel, or tungsten beneficiation, magnetic separation is often used to recover iron minerals or other magnetic components, achieving resource reuse and added value enhancement.

3. Iron Removal and Purification

In non-metallic mineral processing, ceramics, glass, chemical, and food industries, magnetic separators are commonly used to remove iron impurities from materials. For example, in the production of quartz sand, feldspar, and kaolin, magnetic separators can effectively remove trace amounts of iron, thereby improving the purity and transparency of the products. This process not only improves product quality but also prevents iron impurities from causing wear and tear on subsequent processing equipment.

4. Environmental Protection and Waste Treatment

Magnetic separators play an important role in the resource utilization of solid waste. For example, in the treatment of solid waste such as steel slag, waste electrical appliances, and discarded automobiles, magnetic separators can recover iron materials, realizing "turning waste into treasure." Simultaneously, in urban solid waste treatment systems, magnetic separators can be used to separate ferromagnetic metals from waste, reducing landfill volume and promoting the development of a circular economy.

5. Automation and Efficiency of the Separation Process

Modern magnetic separators are compact in structure, easy to operate, and readily automated. By adjusting the magnetic field strength, magnetic system structure, and feed rate, fine separation can be performed according to the material properties, thereby improving separation efficiency and economic benefits.

Main Application Areas of Magnetic Separators

1. Metallurgical and Mining Industry

This is the most traditional and widespread application area of magnetic separators. In iron ore beneficiation, magnetic separators are used to process magnetite, hematite, and limonite, increasing the iron content of the concentrate. Magnetic separation technology also plays a crucial role in the beneficiation of ilmenite, manganese ore, tungsten ore, and tin ore. Furthermore, in non-ferrous metal ores, magnetic separation is commonly used to remove impurities and improve concentrate purity.

2. Building Materials and Chemical Industry

In building materials production, such as cement, ceramics, and glass, the purity requirements for raw materials are extremely high. Magnetic separators can effectively remove iron impurities from raw materials, preventing the finished product from blackening, discoloration, or deterioration of mechanical properties. In the chemical industry, magnetic separators are used to purify quartz sand, talc powder, phosphate rock powder, limestone powder, etc., ensuring stable product quality.

3. Food and Pharmaceutical Industry

In food processing and pharmaceutical production, to prevent metal impurities from contaminating products and causing safety hazards or equipment damage, magnetic separators are used to remove iron filings, iron powder, and metal fragments from raw materials. For example, installing small permanent magnet separators in flour, sugar, tea, and grain processing lines can significantly improve product safety and hygiene standards.

4. Recycling Resources and Environmental Protection Industry

Magnetic separators are widely used in scrap steel recycling, automobile dismantling, electrical appliance recycling, and municipal waste sorting. They can quickly separate ferrous materials for remelting or reuse. Simultaneously, in the treatment of industrial waste such as steel slag and fly ash, magnetic separators can separate iron particles or magnetic micropowder, achieving the dual goals of resource recycling and environmental protection.

5. Scientific Research and Experimental Applications

In universities, research institutes, and materials laboratories, magnetic separators are used to study the magnetic differences and separation performance of different minerals, providing a theoretical basis for optimizing mineral processing technologies. Experimental magnetic separators can precisely control magnetic field strength and separation parameters to meet the high-precision requirements of scientific research experiments.

With technological advancements, magnetic separators are developing towards higher efficiency, energy saving, and intelligence. The application of new permanent magnet materials (such as rare earth neodymium iron boron) has significantly improved the magnetic field strength of magnetic separation equipment and greatly reduced energy consumption. Meanwhile, intelligent magnetic separation systems combining sensor technology and artificial intelligence algorithms can achieve online detection and automatic adjustment, improving sorting accuracy and production efficiency. Furthermore, the emergence of new processes such as dry high-intensity magnetic separation, superconducting magnetic separation, and pulsed high-gradient magnetic separation has opened up new prospects for the application of magnetic separators in complex ore processing.

As a highly efficient and environmentally friendly sorting device, magnetic separators play an increasingly important role in mineral resource development, raw material purification, waste recycling, and environmental governance. In the future, with the development of materials science and intelligent control technology, magnetic separators will inevitably continue to evolve towards higher magnetic fields, lower energy consumption, and higher levels of automation, making greater contributions to achieving efficient resource utilization and green sustainable development.

The development and application of magnetic separators mark a shift in modern sorting technology from traditional physical separation to intelligent and refined processes. With continuous breakthroughs in permanent magnet materials, automatic control, and information technology, magnetic separation equipment is gradually achieving a balance between high magnetic field strength, low energy consumption, and intelligent control. In the future, magnetic separators will demonstrate greater potential and value in areas such as deep development of mineral resources, recycling of solid waste, and environmental governance, becoming an important driving force for promoting industrial upgrading and green development.

Save Time! Get A Detailed Quotation Quickly.