The demand for intelligent, efficient, and green material handling in the industrial sector is increasingly urgent, leading to technological innovation in vibrating screens as key equipment. The new generation of vibrating screens launched in 2025 deeply integrates cutting-edge technologies such as AI, ultrasonic resonance, and the Internet of Things, overcoming the limitations of traditional equipment. It achieves breakthroughs in intelligent control, screening efficiency, energy conservation and environmental protection, and scenario adaptability, solving pain points for multiple industries including mining, pharmaceuticals, and chemicals. The following will analyze its features and advantages in detail from four core dimensions.

Driven by both industrial intelligence and green production, vibrating screen technology has achieved a leapfrog development from "mechanical operation" to "intelligent control," and from "single screening" to "system optimization." The new generation of vibrating screens launched in 2025 integrates cutting-edge technologies such as AI algorithms, ultrasonic resonance, and the Internet of Things, achieving comprehensive upgrades in intelligent control, screening efficiency, energy conservation and environmental protection, and adaptability, providing more efficient material handling solutions for multiple industries including mining, pharmaceuticals, and chemicals. The following will analyze its features and advantages from four core dimensions.

1. Intelligent Control: Full-Process Automation, Say Goodbye to Experience-Based Reliance

The latest vibrating screen completely breaks away from the limitations of traditional equipment's "manual adjustment and blind operation," constructing a full-chain intelligent system of "perception - decision-making - execution - traceability," becoming a core support for refined production.

At the operational interaction level, visualization and convenience are standard features. Taking the Aode-200A intelligent vibrating screen as an example, it is equipped with a 7-inch color LCD touchscreen, presenting functions such as "screening mode selection" and "parameter adjustment" in modular form. Operators can quickly get started without professional training, and it also supports one-click switching between Chinese and English interfaces, adapting to the standardized needs of multinational enterprises. Parameter adjustment has been further upgraded to precision, with amplitude steplessly adjustable from 0-3mm and screening time freely set from 0-999 minutes. Combined with a high-frequency vibration of 3000 times/minute, it can accurately match the characteristics of different materials such as lightweight resin powder and high-density metal powder.

The automation level of data processing has been greatly improved. The new generation of equipment is generally equipped with a RS-232 communication interface, enabling real-time communication with electronic balances and computers. After sieving, it automatically collects the weight of residues at each stage, completely eliminating errors from manual readings. The SMART sieving analysis software automatically calculates 12 core data points, including residue and cumulative pass rate, and instantly generates particle size distribution curves. In the pharmaceutical industry, it can directly output D10/D50/D90 characteristic particle size data conforming to pharmacopoeia standards without secondary processing. Simultaneously, the equipment supports unlimited data storage, with each record linked to sample information and operation trajectory. Reports can be exported in Excel and PDF formats via USB, meeting GMP/GLP compliance traceability requirements.

Remote operation and maintenance and predictive management are new highlights. The WFPS series super multi-frequency sieves can be connected to the Fourier Industrial Internet platform, enabling online monitoring of equipment operating status and fault diagnosis, significantly reducing operation and maintenance costs. Some ultrasonic vibrating screens incorporate AI adaptive learning capabilities, enabling them to accumulate a database of material vibration characteristics, predict agglomeration tendencies caused by humidity changes, and adjust parameters in advance, extending the downtime cleaning frequency from once every 8 hours to once every 72 hours.

2. High-Efficiency Screening: Overcoming Material Limitations, Doubling Processing Capacity

Addressing the pain points of traditional equipment such as low screening efficiency, easy clogging, and insufficient precision, the new generation of vibrating screens has achieved a transformation from "general screening" to "precise adaptation" through technological innovation, showing significant advantages, especially in the processing of difficult-to-screen materials.

The application of ultrasonic resonance technology has revolutionized the logic of fine screening. The Navigate ultrasonic vibrating screen combines 38kHz-40kHz high-frequency ultrasonic energy with mechanical vibration, forming a microscopic "three-dimensional vibration field" on the screen surface. This instantly destroys the surface tension and electrostatic adsorption between materials, completely solving the clogging problem of easily agglomerated materials such as titanium dioxide and ultrafine powders of traditional Chinese medicine. Compared to traditional equipment, its screening accuracy is improved by over 30%, throughput is increased by 2-5 times, and screen life is extended by 50%. The intelligent adjustment system achieves dynamic adaptation; embedded sensors monitor screen load in real time, and AI algorithms analyze material status. When blockage occurs, a high-frequency pulse mode is automatically triggered; when processing lightweight materials, it switches to a low-frequency vibration mode, balancing efficiency and material protection.

The multi-frequency segmented screening technology significantly improves processing capacity. The WFPS super multi-frequency screen innovatively adopts a three-stage design: the first stage uses high-amplitude, low-frequency vibration to disperse materials for uniform distribution; the second stage flexibly adjusts frequency and amplitude according to material characteristics to promote stratified screening; and the third stage uses low-amplitude, high-frequency vibration for secondary purification. Combined with a multi-section, multi-faceted structure, this significantly increases throughput compared to traditional equipment. This design fully utilizes the material's falling and tumbling process to remove inertia, performing particularly well in high-volume scenarios such as coal mining and other industries, while also improving dehydration rate and surface cleaning effect.

The adaptability to special materials has been comprehensively upgraded. For fine powders of 325 mesh or finer, equipment powered by ultrasonic technology can achieve precise grading, avoiding the "missing" and "mis-grading" problems of traditional equipment. For moist and sticky materials, the intermittent sieving mode effectively prevents screen clogging through a preset cycle of "vibration for 30 seconds - pause for 10 seconds." Some equipment even supports multi-layer stacking design (up to 5 layers), completing multi-level grading in a single run, significantly improving production efficiency.

3. Energy Saving and Environmental Protection: Practicing Green Production and Reducing Costs Throughout the Lifecycle

Driven by the "dual carbon" goal, the new generation of vibrating screens has undergone comprehensive optimization from structural design to energy utilization, achieving a dual reduction in energy consumption and pollution, becoming an important contributor to the green transformation of enterprises.

Energy consumption control reaches a new level. The WFPS series adopts FCD-i energy-saving technology, through the intelligent collaboration of two motors (one main and one auxiliary) and an energy storage battery, using big data algorithms to regulate motor start-up, shutdown, and charging, reducing overall power consumption by 35%-50%, while achieving rapid shutdown to extend equipment life. Through technological optimization, ultrasonic vibrating screens reduce power consumption by 40% compared to traditional models and eliminate the need for screening aids, reducing chemical pollution and further saving costs. Furthermore, the equipment generally adopts a lightweight design; the weight of a single multi-frequency screen is only 30%-40% of that of conventional equipment, resulting in a small vibrating mass and further reducing operating energy consumption.

Pollution control achieves source reduction. The application of static sealing technology prevents the screen box from participating in vibration. Combined with polyester fiber sound-absorbing panels, this reduces noise pollution and lowers dust collection airflow by more than 40%, significantly reducing the energy consumption of the dust collection system. Navigate ultrasonic vibrating screens feature a fully enclosed structure and negative pressure dust collection design. Made of food-grade stainless steel with airtight technology, they achieve zero dust spillage, meeting the clean production requirements of industries such as pharmaceuticals and lithium batteries. Some multi-frequency screens are even equipped with a dust collection system that eliminates the need for additional dust collection pipelines, achieving zero dust emissions while reducing user infrastructure costs and dust collection power consumption.

The environmental friendliness of the equipment throughout its lifecycle is significantly improved. The core components are designed for long lifespan; for example, the core components of the ultrasonic vibrating screen have a lifespan exceeding 100,000 hours, reducing equipment replacement frequency. The extensive use of recyclable materials further reduces waste generation, aligning with sustainable development principles.

4. Flexible Adaptability: Modular Design Covers Diverse Scenarios

The new generation of vibrating screens breaks the limitation of "one machine for one use" through modular and scalable structural innovation. It can flexibly adapt to the production needs of different industries and capacities, significantly improving equipment utilization and return on investment.

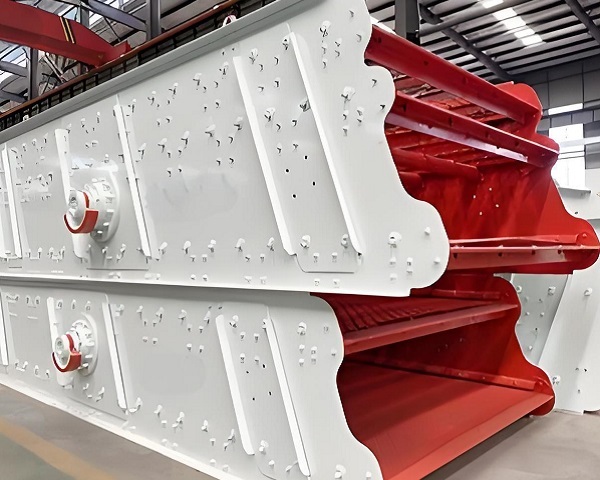

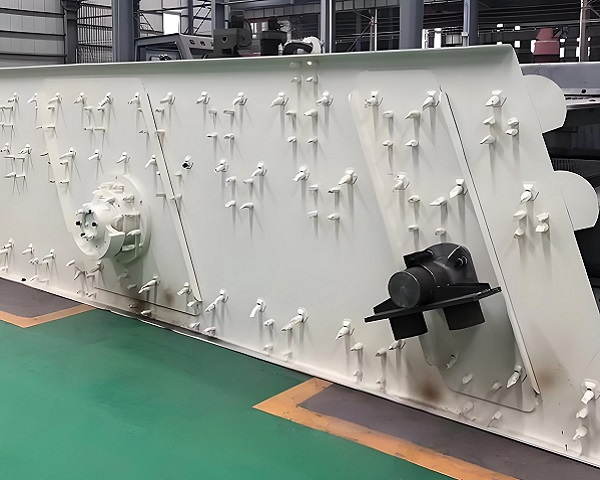

Modular design simplifies installation and maintenance. The multi-frequency screen adopts a segmented design, which not only reduces the requirements for steel strength but also makes disassembly and hoisting more convenient, especially suitable for mining and construction industries that require frequent site relocation, significantly reducing relocation costs. The application of quick-disassembly modules shortens screen replacement time to within 5 minutes, and combined with an automatic lubrication system, significantly reduces the labor intensity of operators.

Functional expandability meets personalized needs. The equipment can be flexibly equipped with auxiliary systems according to scenario requirements, such as adding a dust collection system for dust control, adding an ultrasonic module for fine screening, and connecting to a PLC control system for automated production lines. In terms of mode adaptation, the device has multiple built-in preset programs. The Aode-200A sieve analyzer covers three basic modes: "continuous sieve," "intermittent sieve," and "timed sieve," and also supports a custom workgroup mode, storing industry-standard sieve sequences for easy later recall.

Its multi-industry adaptability is comprehensively enhanced. In the mining sector, the multi-frequency sieve can process large-diameter ores, meeting the production capacity demand of hundreds of tons per hour; in the pharmaceutical industry, the intelligent sieve analyzer's compliant design adapts to pharmacopoeia standards; in the chemical industry, corrosion-resistant materials and explosion-proof design can handle corrosive, flammable, and explosive materials; in the food industry, its clean structure and easy-to-clean characteristics meet food safety requirements. This all-scenario adaptability makes the new generation of vibrating screens a universal solution for cross-industry material handling.

The latest vibrating screen in 2025, with its four major advantages—intelligent control, high-efficiency sieve, energy saving and environmental protection, and flexible adaptability—has become a new choice for industrial material handling. It not only improves production efficiency and reduces costs but also aligns with the trend of green production. As technology continues to evolve, it will become more adaptable to more complex scenarios, providing strong support for various industries to optimize production processes and achieve sustainable development, thus propelling the field of industrial material handling to new heights.

Save Time! Get A Detailed Quotation Quickly.