In the field of industrial production and material handling, vibrating screens, as a highly efficient separation device, have become a key piece of equipment connecting various stages of material processing due to their unique vibration principle and flexible structural design. Through the periodic vibration generated by a vibration source, it causes materials to undergo complex trajectories on the screen surface. Utilizing the differences in particle size, density, and shape, it achieves grading, impurity removal, and dewatering of materials of different specifications, widely serving multiple industries such as mining, construction, chemicals, and food. The following will provide a detailed analysis from two aspects: the core function of vibrating screens and typical application scenarios.

The Core Function of Vibrating Screens: From Basic Separation to Fine Processing

The function of vibrating screens revolves around "material processing optimization," covering the entire process from rough processing to refined production. Specifically, it can be divided into five core functions, each corresponding to a key pain point in industrial production, providing a guarantee for the efficient operation of subsequent processes.

1. Material Grading: Achieving Standardized Screening to Meet Differentiated Needs

Material grading is the most basic and widely used function of vibrating screens. In most production scenarios, raw materials or semi-finished products are often mixtures of different particle sizes, requiring grading and screening to separate materials of specific specifications that meet process requirements. Its working logic is as follows: Different screen mesh sizes are used according to production needs. When the mixed material enters the vibrating screen, under the vibration force, particles smaller than the screen mesh size pass through the mesh and fall into the lower receiving device, becoming "undersize material"; particles larger than the mesh size move along the screen surface and are discharged from the outlet, becoming "oversize material".

Taking the processing of building aggregate as an example, natural aggregate raw materials contain various particle sizes, including 0-5mm stone powder, 5-10mm fine sand, 10-20mm medium sand, and 20-30mm coarse sand. Through the grading process of a multi-layer vibrating screen (usually 2-3 layers of screens), different sizes of aggregate can be separated in one step. The 0-5mm stone powder can be used to make dry mortar, the 5-20mm aggregate can be used as concrete aggregate, and the 20-30mm coarse sand is suitable for roadbed filling, achieving "multi-purpose use" and improving raw material utilization. Furthermore, in the coal industry, vibrating screens can grade raw coal into lump coal (greater than 25mm), mixed coal (13-25mm), and fine coal (6-13mm), etc. Different specifications of coal correspond to different application scenarios—lump coal is mostly used for combustion in industrial boilers, while fine coal is suitable for power plant power generation, meeting the needs of different customers.

2. Impurity Removal and Purification: Removing impurities and improving material purity. In fields with extremely high requirements for material purity, such as food processing, pharmaceutical production, and chemical raw material processing, the "impurity removal and purification" function of vibrating screens is particularly crucial. In these scenarios, raw materials or semi-finished products may be mixed with foreign objects (such as metal scraps, dirt, hair, lumps, etc.). If not removed in time, this will not only affect product quality but may also damage subsequent processing equipment (such as crushers and granulators), and even cause safety hazards (such as metal impurities in food potentially harming human health). Vibrating screens remove impurities in two ways: First, they utilize "particle size difference removal." When the particle size of impurities mixed in the material differs significantly from that of the target material, a screen with an appropriate aperture is selected, allowing the target material to pass through the screen while the impurities remain on the screen surface (or vice versa). Second, they combine "density difference removal." Some vibrating screens (such as airflow vibrating screens) introduce airflow assistance, utilizing the density difference between the impurities and the target material. Under the combined action of vibration and airflow, lightweight impurities (such as dust and hair) are separated out.

Taking flour processing as an example, after wheat is ground, the flour may contain impurities such as bran fragments, stones, and metal shavings. In this case, the vibrating screen is equipped with a fine screen of 100-120 mesh (approximately 0.15-0.125mm aperture). Flour particles can pass through the screen smoothly, while bran fragments, stones, and other impurities are trapped due to their larger particle size. At the same time, a suction device is installed above the screen to remove lightweight dust from the flour, ultimately resulting in pure flour. In the pharmaceutical industry, during the production of traditional Chinese medicine powder, vibrating screens remove fibrous impurities and agglomerated particles generated during the grinding of medicinal materials, ensuring that the fineness and purity of the powder meet pharmacopoeia standards and preventing any impact on efficacy or safety issues.

3. Dehydration and Media Removal: Reducing Material Moisture Content and Separating Auxiliary Media

In industries such as mining, coal, and environmental protection, materials often contain large amounts of moisture or auxiliary processing media (such as magnetite powder used in mineral processing and coal washing water used in coal washing). If not treated promptly, this increases material transportation costs, affects subsequent processing efficiency (e.g., damp materials easily agglomerate, making it difficult to enter the dryer), and can even cause environmental pollution. The "dehydration and media removal" function of vibrating screens accelerates the separation of moisture or media from materials through vibration, reducing the material's moisture content and recovering recyclable media.

Taking coal washing processes as an example, after raw coal is washed by a coal washing machine, it carries a large amount of coal washing water and magnetite powder (i.e., the "media") used to adsorb impurities. At this stage, the vibrating screen (usually a "dewatering screen") employs a double-layer screen design: the upper screen (approximately 1mm aperture) separates large coal pieces, while the lower screen (approximately 0.5mm aperture) separates fine coal. Simultaneously, a water spray device and a media recovery tank are installed below the screen. The water spray washes away residual magnetite powder from the coal surface; the resulting mixture of water and media flows into the recovery tank, where a magnetic separator separates the magnetite powder for reuse in the coal washing process. After vibration and washing, the coal's moisture content can be reduced from over 30% to below 15%, facilitating subsequent drying, storage, and transportation. In the environmental protection industry, during the dewatering process of sludge after wastewater treatment, vibrating screens (such as "dewatering vibrating screens") can separate free water from the sludge, reducing its moisture content from over 80% to around 60%, forming a low-moisture sludge cake. This reduces sludge volume and lowers the cost of subsequent landfill or incineration.

4. Material Conveying: Assisting in Short-Distance Material Transfer and Connecting Production Processes

Besides its separation function, vibrating screens also possess a certain "material conveying" function. While separating materials, they can simultaneously achieve short-distance (typically 1-5 meters) material transfer, reducing the number of conveying devices on the production line and simplifying the process. The conveying principle is as follows: the screen surface of the vibrating screen is designed with a certain inclination angle (usually 5°-15°). Under the action of the vibration source, the material moves along the inclined screen surface in a jumping or sliding motion, moving from the feed end to the discharge end, ultimately completing the dual tasks of separation and conveying.

In modern industrial production systems, material handling efficiency directly affects overall production capacity. As a high-efficiency separation device, the vibrating screen, with its flexible vibration principle and multi-dimensional structural design, has become the "material handling hub" in many industries such as mining, construction, and food. It can complete key processes such as grading, impurity removal, and dewatering based on the differences in material particle size, solving the pain point of chaotic mixed material specifications and building a solid quality defense line for subsequent processing. This article will delve into the five core functions of vibrating screens and, through six typical industry scenarios, demonstrate their irreplaceable role in industrial production.

This function is particularly useful in small and medium-sized production lines. For example, in the feed processing industry, raw materials such as soybean meal and corn flour, after being crushed, need to be screened through a vibrating screen to obtain powder of the required fineness before being conveyed to a mixer for batching and mixing. In this case, the feed end of the vibrating screen is connected to the discharge port of the crusher, and the discharge end is directly connected to the feed port of the mixer. The screen surface inclination angle is set to 8°-10°. The material naturally moves towards the mixer during the screening process, eliminating the need for an additional belt conveyor, thus saving equipment investment and reducing the floor space required for the production line. In the ceramics industry, ceramic raw materials (such as kaolin and quartz sand) are ground in a ball mill and then screened through a vibrating screen to obtain fine particles. Simultaneously, these particles are conveyed along the inclined screen surface to the slip casting equipment, preventing waste and improving production continuity.

5. Inspection and Screening: Verifying Material Quality and Controlling Production Precision

In the "finished product inspection" or "intermediate process inspection" stages of industrial production, the "inspection and screening" function of vibrating screens is crucial for ensuring product quality. Its core purpose is to check whether the particle size distribution of the material meets production standards through screening. If non-compliant materials are found (e.g., too many oversized particles), feedback is promptly sent to the preceding process (e.g., adjusting the grinding gap of the crusher or the speed of the classifier) to prevent unqualified materials from entering the next process and causing batch quality problems.

Taking cement production as an example, after cement clinker is ground, it needs to be inspected and screened using a vibrating screen: If the proportion of oversize material (particles larger than 0.08mm) exceeds 5%, it indicates that the cement fineness does not meet the standard (usually, the 0.08mm sieve residue should not exceed 10%). The grinding time of the ball mill or the steel ball gradation needs to be adjusted to ensure the cement fineness meets the standard. If the proportion of oversize material is acceptable, the cement can enter the homogenization silo for subsequent packaging or bulk distribution. In the electronics industry, during the production of epoxy resin powder for chip packaging, vibrating screens use a 200-mesh sieve (approximately 0.075mm aperture) for inspection and sieving. If clumps or coarse particles are found on the sieve, it indicates poor dispersion of the epoxy resin powder, requiring re-grinding or the addition of a dispersant to avoid affecting the sealing and conductivity of the chip packaging.

Typical Application Scenarios of Vibrating Screens: Covering Customized Needs Across Multiple Industries

The wide range of applications for vibrating screens stems from their customizable structure based on the material characteristics and process requirements of different industries (e.g., adjusting the sieve material, vibration frequency, number of sieve layers, and whether auxiliary devices are included). This allows them to adapt to diverse processing needs, from coarse and heavy materials to fine powders, and from high-temperature materials to flammable and explosive materials. The following is an analysis of application scenarios in six typical industries:

1. Mining Industry: Full-Process Adaptation from Ore Extraction to Mineral Processing

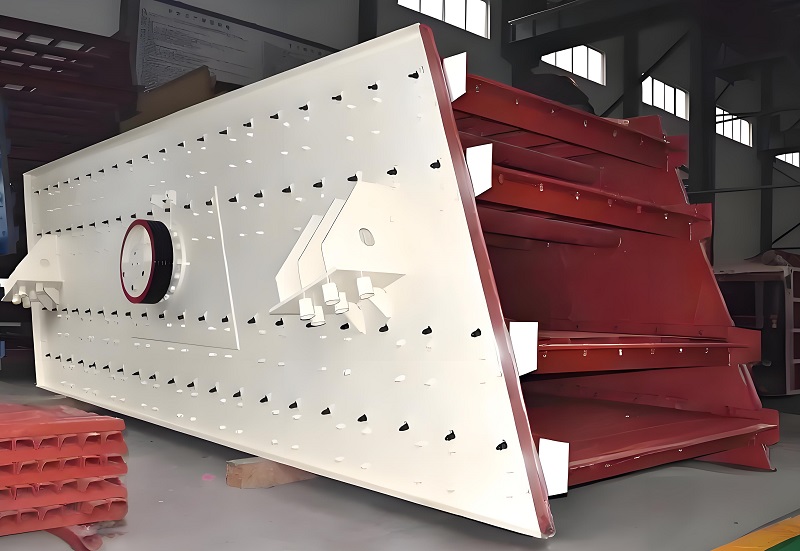

The mining industry is the "core application area" for vibrating screens, covering almost every stage of ore extraction, crushing, mineral processing, and tailings treatment. The materials to be processed are characterized by "high hardness, large particle size, and high output requirements." Therefore, vibrating screens used in mining typically employ a "heavy-duty structural design," with screen materials primarily made of wear-resistant manganese steel and polyurethane. The vibration source power is relatively high (usually 5-22kW) to meet the processing capacity requirements of tens to hundreds of tons per hour.

In the ore extraction stage, vibrating screens are mainly used for "pre-screening before coarse crushing": The raw ore extracted from open-pit mines may contain a large amount of gravel with a particle size less than 50mm (which does not require coarse crushing). If directly fed into a jaw crusher, it would increase the crusher's load and reduce crushing efficiency. At this stage, the vibrating screen (usually a "heavy-duty vibrating screen") is equipped with a 50mm aperture screen to separate gravel smaller than 50mm, which then directly enters the medium crushing stage. Ore larger than 50mm enters the jaw crusher for coarse crushing, improving the overall efficiency of the crushing production line. In mineral processing, the application of vibrating screens is more specialized: in gold ore beneficiation, in the combined "screening-gravity separation" process, vibrating screens can classify the ground gold ore powder into sizes such as 0-0.1mm and 0.1-0.3mm. Different sizes of gold ore powder correspond to different gravity separation equipment (such as shaking tables and jigs), improving gold recovery rates. In iron ore beneficiation, vibrating screens ("demagnetizing screens") can remove magnetic impurities from iron concentrate, avoiding affecting the separation effect of magnetic separators. In tailings treatment, vibrating screens can separate coarse particles (such as stones larger than 1mm) from the tailings. These coarse particles can be used for mine road paving, while fine tailings are stored in tailings ponds, realizing the resource utilization of tailings. 2. Building Materials Industry: Ensuring the Quality of Sand, Gravel, Cement, and Ceramic Raw Materials

The building materials industry has extremely high requirements for the "uniformity of specifications" of materials (e.g., the particle size uniformity of sand and gravel directly affects the strength of concrete). Vibrating screens are mainly used in this industry for "material grading" and "impurity removal." The equipment is mostly medium-sized with a moderate processing capacity (10-50 tons per hour). The screen material is selected according to the characteristics of the material (e.g., manganese steel screens are used for sand and gravel screening, and stainless steel screens are used for cement screening). In the sand and gravel processing industry, in addition to the natural sand and gravel grading mentioned earlier, vibrating screens are key equipment for "post-shaping screening" in artificial sand production lines. After granite, basalt, and other ores are shaped by a sand making machine, artificial sand of different particle sizes is produced. The vibrating screen uses 2-3 layers of screens (with apertures of 20mm, 10mm, and 5mm) to grade the artificial sand into four specifications: 20-30mm, 10-20mm, 5-10mm, and 0-5mm. Among them, the 5-20mm artificial sand can be directly used in commercial concrete, and the 0-5mm stone powder can be used in dry mortar, achieving "full particle size utilization." In the cement industry, in addition to being used for inspecting and screening cement powder, vibrating screens can also be used for "impurity removal from cement raw materials." Before cement raw materials (composed of limestone, clay, and iron powder) enter the rotary kiln for calcination, they may contain large pieces of limestone and metal impurities. Vibrating screens can separate these impurities, preventing blockage of the rotary kiln feed inlet or damage to the refractory bricks inside the kiln. In the ceramics industry, vibrating screens are used for the "fine screening" of ceramic raw materials: after grinding materials such as kaolin and feldspar in a ball mill, they need to pass through a 120-200 mesh vibrating screen to remove insufficiently ground coarse particles and impurities, ensuring uniform fineness of the ceramic raw materials and preventing defects such as spots and cracks in the fired ceramic products.

3. Food Industry: Refined Processing Balancing Safety and Efficiency The core requirements for vibrating screens in the food industry are "hygiene and safety" and "fine separation." Therefore, the equipment is mostly made of 304/316 stainless steel (corrosion-resistant and easy to clean), and the screens are mainly nylon or stainless steel woven screens (to avoid metal contamination). Some equipment is also equipped with "explosion-proof motors" (for flammable and explosive materials, such as flour) and "cleaning devices" (such as CIP online cleaning systems), complying with the GMP (Good Manufacturing Practice) standards of the food industry. In the grain processing industry, vibrating screens can be used for "grain cleaning" and "flour grading": After harvesting grains such as wheat and rice, impurities such as weeds, stones, and soil will be mixed in. The vibrating screen ("grain cleaning screen") will first separate the weeds and stones (by utilizing the difference in particle size) through multiple layers of screens and a suction device, and then suck away the light dust to obtain clean grains. In flour processing, vibrating screens can grade different grades of flour (such as grade 1 flour, grade 2 flour, and standard flour). Grade 1 flour needs to pass through a 120-mesh screen, and grade 2 flour needs to pass through a 100-mesh screen to meet the needs of different food production (such as grade 1 flour for pastries and standard flour for steamed buns). In the fruit and vegetable processing industry, vibrating screens can be used for "dehydration after fruit and vegetable washing" and "sieving of fruit and vegetable powders": After washing, berries such as strawberries and blueberries have a lot of water adhering to their surface. Vibrating screens ("fruit and vegetable dehydration screens") can quickly remove surface water through high-frequency, low-amplitude vibration, preventing the berries from rotting. In the production of fruit and vegetable powders such as carrot powder and apple powder, vibrating screens can remove lumps of particles from the powder, ensuring the flowability of the powder and facilitating subsequent packaging and reconstitution. In the confectionery and chocolate industry, vibrating screens are used for "sugar granule grading" and "cocoa powder impurity removal": In confectionery production, vibrating screens can grade sugar granules after boiling into different sizes for making different specifications of hard candy; in cocoa powder processing, vibrating screens can remove the shells and residues produced during cocoa bean grinding, ensuring the purity and taste of the cocoa powder.

4. Chemical Industry:

Adaptable to the Special Needs of Corrosive, Flammable, and Explosive Materials

The materials used in the chemical industry are often characterized by corrosivity, flammability, explosiveness, and toxicity, placing extremely high demands on the corrosion resistance and safety of vibrating screens. Therefore, chemical vibrating screens are mostly made entirely of stainless steel (316L stainless steel, resistant to strong acids and alkalis), with a tightly sealed structure (to prevent material leakage and environmental pollution). Some equipment is also equipped with anti-static devices and explosion-proof motors (e.g., when handling flammable and explosive materials such as flour and plastic granules). The screen body is also designed for easy disassembly and cleaning, meeting the clean production requirements of the chemical industry.

In the fine chemical field, vibrating screens can be used for the screening of pigments and dyes: In the production of pigments such as titanium dioxide and lithopone, the ground pigment powder may contain agglomerated particles. Vibrating screens ("fine vibrating screens") are equipped with 200-300 mesh screens to separate these agglomerated particles, ensuring uniform pigment fineness and preventing interference with the coloring effect of coatings and plastics. In dye production, vibrating screens can remove impurities from dyes, ensuring dye purity and preventing color spots during dyeing. In the field of polymer materials, vibrating screens are used for "grading plastic and rubber granules": In the production of plastic granules such as polyethylene and polypropylene, vibrating screens can grade plastic granules of different sizes (e.g., 2-3mm, 3-4mm), ensuring uniform particle size and facilitating subsequent injection molding (uneven particle size leads to inconsistent thickness of injection molded parts). In rubber granule production, vibrating screens can remove metallic impurities (such as steel wire mixed in during vulcanization) from rubber granules, preventing them from affecting the elasticity and service life of rubber products. In the fertilizer industry, vibrating screens are used for "screening fertilizer granules": In the production of granular fertilizers such as urea and compound fertilizers, vibrating screens can separate unqualified small particles (particle size less than 1mm) and agglomerated particles (particle size greater than 5mm). Qualified particles (1-5mm) enter the packaging stage, while small particles can be re-granulated, improving raw material utilization. In addition, vibrating screens can also be used for "raw material impurity removal" in fertilizer production, such as removing stones and soil from potassium chloride to ensure fertilizer purity.

5. Environmental Protection Industry: Facilitating the Green Transformation of Solid Waste and Wastewater Treatment

With increasingly stringent environmental requirements, vibrating screens are finding wider application in the environmental protection industry, primarily for "solid waste treatment" and "wastewater treatment." The core objectives are to achieve "resource recovery" and "compliant emissions." These devices are characterized by "wear resistance, easy cleaning, and adaptability to various waste materials." Some equipment is also equipped with "dust covers" and "sound insulation devices" to reduce secondary pollution.

In the field of solid waste treatment, vibrating screens can be used for "resource recovery of construction waste" and "sorting of municipal solid waste": After construction waste (such as concrete blocks and bricks) is crushed by a crusher, the vibrating screen can classify the crushed material into specifications such as 0-5mm, 5-20mm, and 20-50mm. Among them, the 0-5mm material can be used to make recycled mortar, the 5-20mm material can be used to make recycled concrete aggregate, and the 20-50mm material can be used for roadbed filling, realizing the "reduction and resource recovery" of construction waste; In the sorting of municipal solid waste (such as pretreatment before incineration), the vibrating screen can separate inorganic matter (such as stones and glass) and organic matter (such as kitchen waste) from municipal solid waste. Inorganic matter can be landfilled, and organic matter can be used for composting or incineration power generation, improving the treatment efficiency of municipal solid waste. In the field of wastewater treatment, vibrating screens can be used for both wastewater pretreatment and sludge dewatering. Industrial wastewater (such as dyeing and printing wastewater, and papermaking wastewater) often contains a large amount of suspended solids (such as fibers and dye particles). Vibrating screens ("wastewater screening machines") can separate these suspended solids before the wastewater enters the sedimentation tank, reducing the load on subsequent wastewater treatment. During the sludge dewatering process after wastewater treatment, vibrating screens ("sludge dewatering screens") can separate free water from the sludge, reducing its moisture content and facilitating subsequent disposal.

With its core functions of grading, impurity removal, and dewatering, vibrating screens are suitable for diverse scenarios such as heavy-duty operations in mining and fine processing in food, becoming a key piece of equipment connecting various stages of industrial production. With increasing environmental protection requirements and the development of automation technology, vibrating screens are upgrading towards high efficiency, energy saving, and intelligent control. In the future, they will play a more important role in resource recycling and green production, providing strong support for cost reduction, efficiency improvement, and sustainable development in various industries, continuously consolidating their core position in the material handling field.

Save Time! Get A Detailed Quotation Quickly.